Material weighing major data detection and packaging intelligent control system

An intelligent control system and data detection technology, applied in electric controllers, controllers with specific characteristics, etc., can solve the problem of strong interference and large lag, accurate weighing and reliable packaging, and affect the accurate operation and reliability of material weighing and packaging processes. management and other issues, to achieve the effect of uniform movement, accurate weighing, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

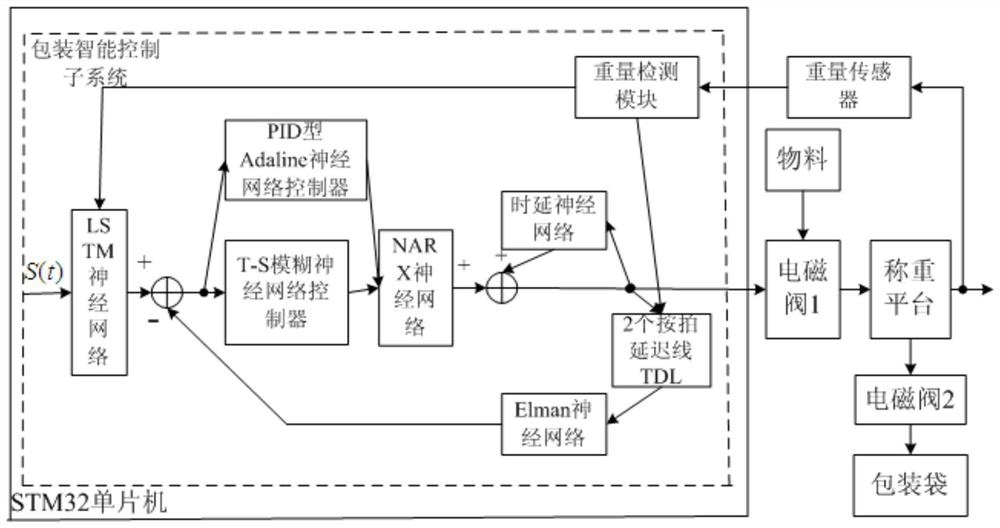

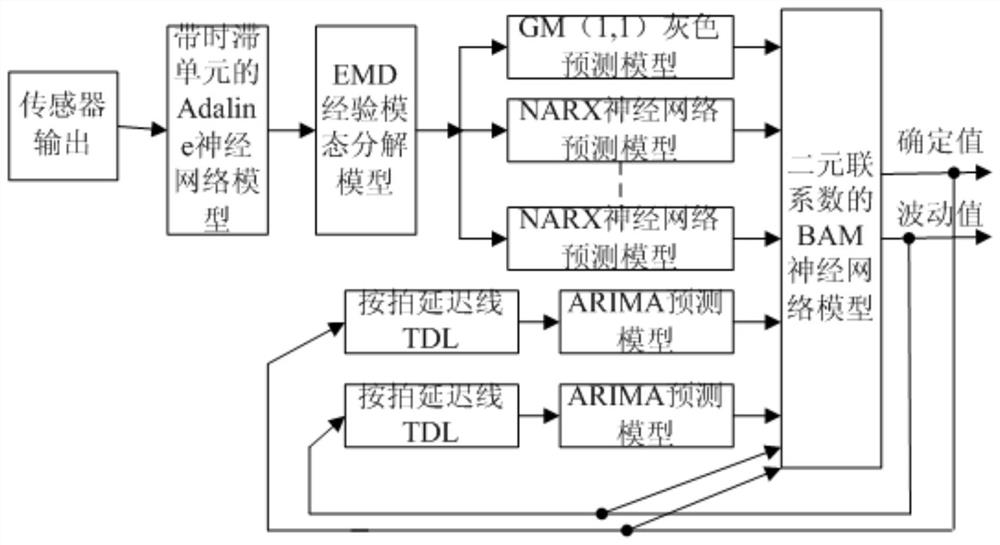

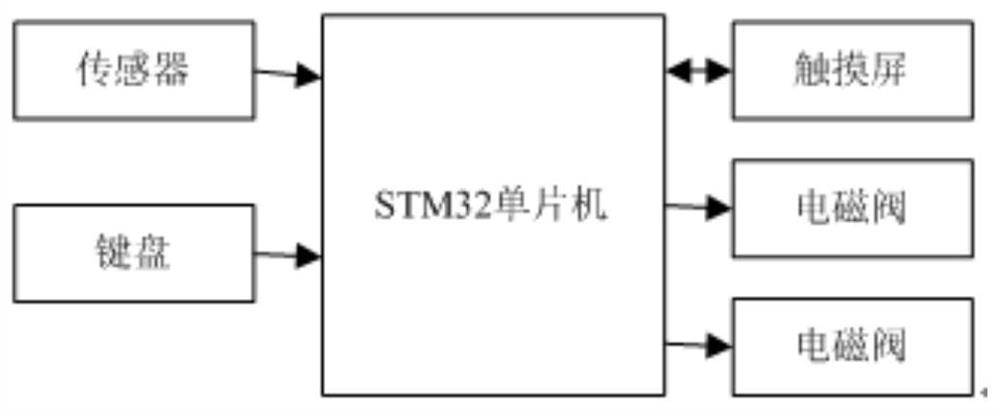

[0026] combined with Figure 1-3 , further describe the technical solution of the present invention:

[0027] 1. Design of the overall function of the system

[0028] The invention realizes automatic control of the weighing and packaging process of materials, and the system is composed of a parameter acquisition and control platform and a packaging intelligent control subsystem. The parameter acquisition and control platform consists of STM32 single-chip microcomputer, weight sensor, material, 2 solenoid valves, weighing platform and packaging bag. The weight sensor collects the weight of the material on the weighing platform and inputs it into the STM single-chip microcomputer. The output adjustment of the packaging intelligent control subsystem corresponds to The opening of the solenoid valve makes the material drop onto the weighing platform in a balanced manner and meet the expected value of the material set by the system. When the weight of the material on the weighing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com