Preparation method of red bean water

A technology of red bean and raw material, applied in the field of beverage processing, can solve the problems of perishability, harm to health, short shelf life, etc., and achieve the effects of safe ingredients, fresh flavor and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

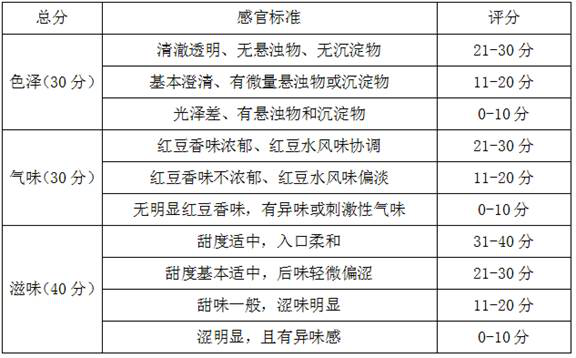

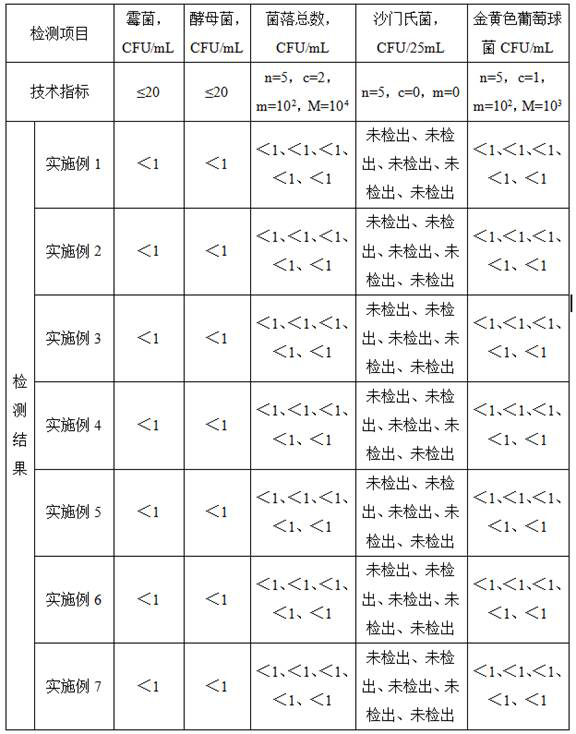

Examples

Embodiment 1

[0031] The application provides a kind of preparation method of red bean water, adopts following technical scheme:

[0032] A preparation method of red bean water, specifically comprising the following steps:

[0033] S1. Wash the red beans, white fungus, shiitake mushrooms and Gorgon fruit respectively, and then dry them at 58°C until the water content is 7%. In parts by weight, the preferred raw materials are 50 parts of red beans, 20 parts of white fungus, 8 parts of shiitake mushrooms and 10 parts of Gorgon fruit, the above-mentioned raw materials are jointly added in the pulverizer, and the pulverization is uniform to obtain a mixed micropowder with a particle size of 10 μm;

[0034] S2. The ratio of material to liquid is 1:9, and the mixed micropowder is added to deionized water. At a temperature of 50°C, ultrasonic-microwave extraction is performed for 20 minutes. The ultrasonic power is controlled to 200W and the microwave power is 300W, and then the temperature is rai...

Embodiment 2

[0038] The application provides a kind of preparation method of red bean water, adopts following technical scheme:

[0039] A preparation method of red bean water, specifically comprising the following steps:

[0040] S1. Wash red beans, white fungus, shiitake mushrooms and Gorgon fruit respectively, and then dry them at 60°C until the water content is 6%. In parts by weight, the preferred raw materials are 55 parts of red beans, 22 parts of white fungus, 9 parts of shiitake mushrooms and 12 parts of Gorgon fruit, the above-mentioned raw materials are jointly added in the pulverizer, and pulverized evenly to obtain a mixed micropowder with a particle size of 30 μm;

[0041]S2. The ratio of material to liquid is 1:10, and the mixed micropowder is added to deionized water. At a temperature of 55°C, ultrasonic-microwave extraction is performed for 25 minutes. The ultrasonic power is controlled to 250W and the microwave power is 350W, and then the temperature is raised to 92°C for...

Embodiment 3

[0045] The application provides a kind of preparation method of red bean water, adopts following technical scheme:

[0046] A preparation method of red bean water, specifically comprising the following steps:

[0047] S1. Wash red beans, white fungus, shiitake mushrooms and Gorgon fruit respectively, and then dry them at 64°C until the water content is 5%. In parts by weight, the preferred raw materials are 60 parts of red beans, 24 parts of white fungus, 10 parts of shiitake mushrooms and 15 parts of Gorgon fruit, the above-mentioned raw materials are jointly added in the pulverizer, and pulverized evenly to obtain a mixed micropowder with a particle size of 50 μm;

[0048] S2. The ratio of material to liquid is 1:11, and the mixed micropowder is added to deionized water. At 60°C, conduct ultrasonic-microwave extraction for 30 minutes, control the ultrasonic power to 300W, and the microwave power to 400W, then raise the temperature to 95°C, and heat-preserve for 4 hours. Col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com