Additive for improving performance of calcium-based desulfurizer and application thereof

A desulfurization agent and additive technology, applied in the field of desulfurization, can solve the problems of low sulfur capacity, low desulfurization efficiency, and low Ca utilization rate, and achieve the effects of increasing specific surface area, improving desulfurization efficiency, and enhancing capture capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

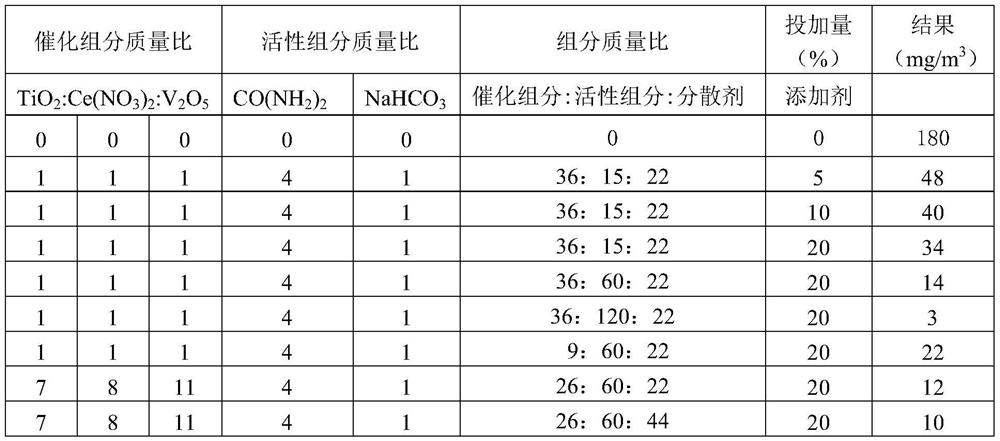

Embodiment 1

[0035] In the laboratory, the desulfurization performance of the desulfurizer is evaluated by using a suspension reaction furnace: the feeding amount of the desulfurizer is 1g, SO 2 The initial concentration is 250mg / m 3 , using unmodified Ca(OH) 2 , the flue gas concentration at the outlet of the reactor was detected to be 180mg / m 3 , cannot meet ultra-low emission standards.

Embodiment 2

[0037] Additives are prepared according to the following mass ratios: TiO 2 :Ce(NO 3 ) 2 :V 2 o 5 =1:1:1, CO(NH 2 ) 2 :NaHCO 3 =4:1, catalytic component: active component: dispersant = 36:15:22.

[0038] In the laboratory, the desulfurization performance of the desulfurizer is evaluated by using a suspension reaction furnace: the feeding amount of the desulfurizer is 1g, SO 2 The initial concentration is 250mg / m 3 , the above additives are added to Ca(OH) according to the mass ratio of 5% 2 In, mixed with additive modified Ca(OH) 2 , the flue gas concentration at the outlet of the reactor was detected to be 48mg / m 3 , to meet emission standards.

Embodiment 3

[0040] Additives are prepared according to the following mass ratios: TiO 2 :Ce(NO 3 ) 2 :V 2 o 5 =1:1:1, CO(NH 2 ) 2 :NaHCO 3 =4:1, catalytic component: active component: dispersant = 36:15:22.

[0041] In the laboratory, the desulfurization performance of the desulfurizer is evaluated by using a suspension reaction furnace: the feeding amount of the desulfurizer is 1g, SO 2 The initial concentration is 250mg / m 3 , the above additives are added to Ca(OH) according to the mass ratio of 10% 2 In, mixed with additive modified Ca(OH) 2 , the flue gas concentration at the outlet of the reactor was detected to be 40mg / m 3 , which can meet the over-discharge standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com