Steel pipe inner wall cleaning device

A technology for cleaning device and inner wall of steel pipe, applied in metal processing equipment, milling machine equipment, grinder and other directions, can solve the problems of insufficient cleaning force and unsatisfactory inner wall cleaning effect, and achieve high production efficiency, ingenious structural design, and thorough cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be clearly and completely described below in conjunction with specific embodiments.

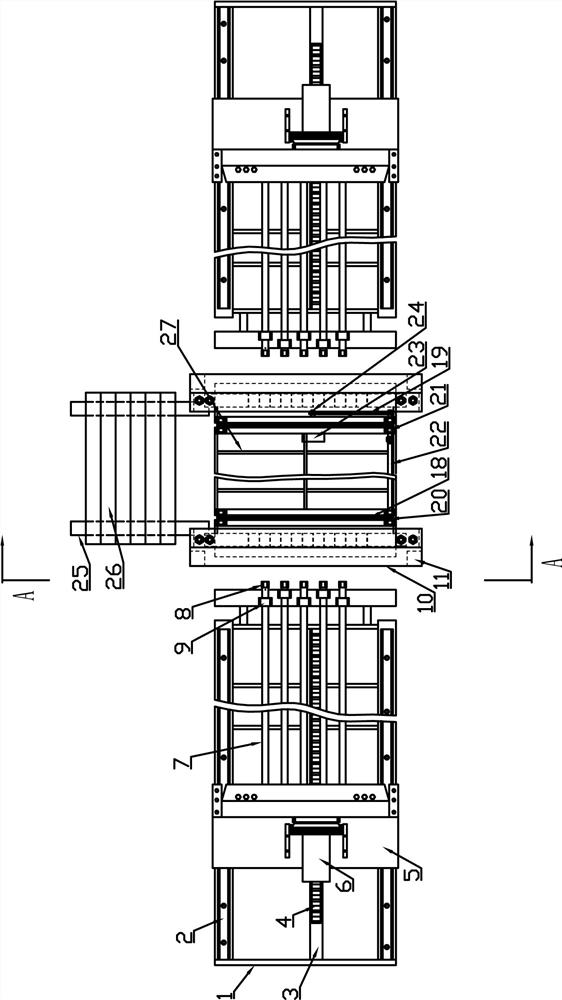

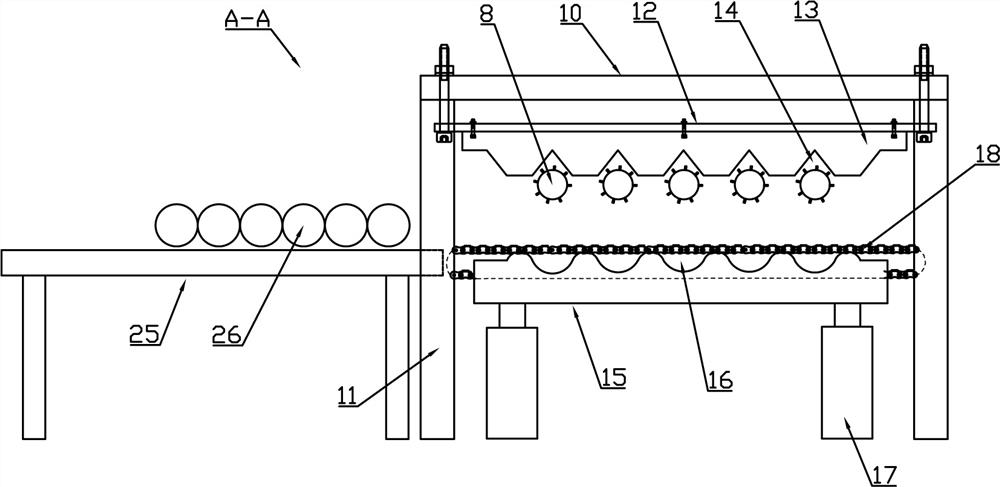

[0032] like Figure 1-Figure 3 Shown is a steel pipe inner wall cleaning device, which includes:

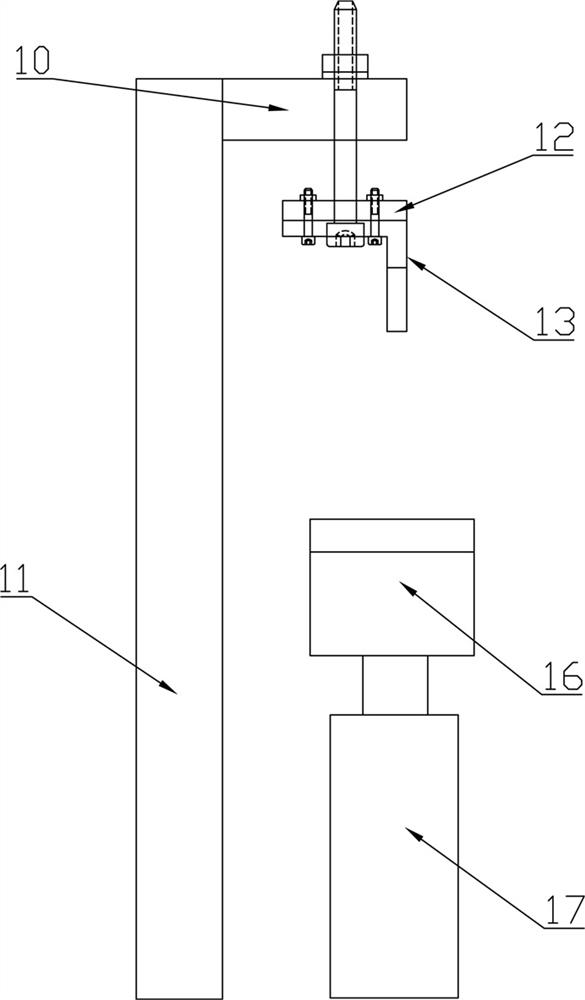

[0033] The slide rail trolley 5, which can move left and right is arranged on the slide rail frame 1, and the right side of the slide rail trolley 5 is horizontally equipped with several milling cutter bars 7, and the left end of the milling cutter bar 7 is connected with the rotary driving device. The right end is fixed with a milling head 8; the rotary drive device is used to drive a number of milling cutter bars 7 to rotate, which is a plurality of drive motors, or drives all milling cutter bars 7 to rotate through a drive motor and chain sprocket drive assembly, The setting method is a conventional technical means in the mechanical field, and will not be repeated here....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap