Method for preparing 1-chloroacetaldehyde oxime

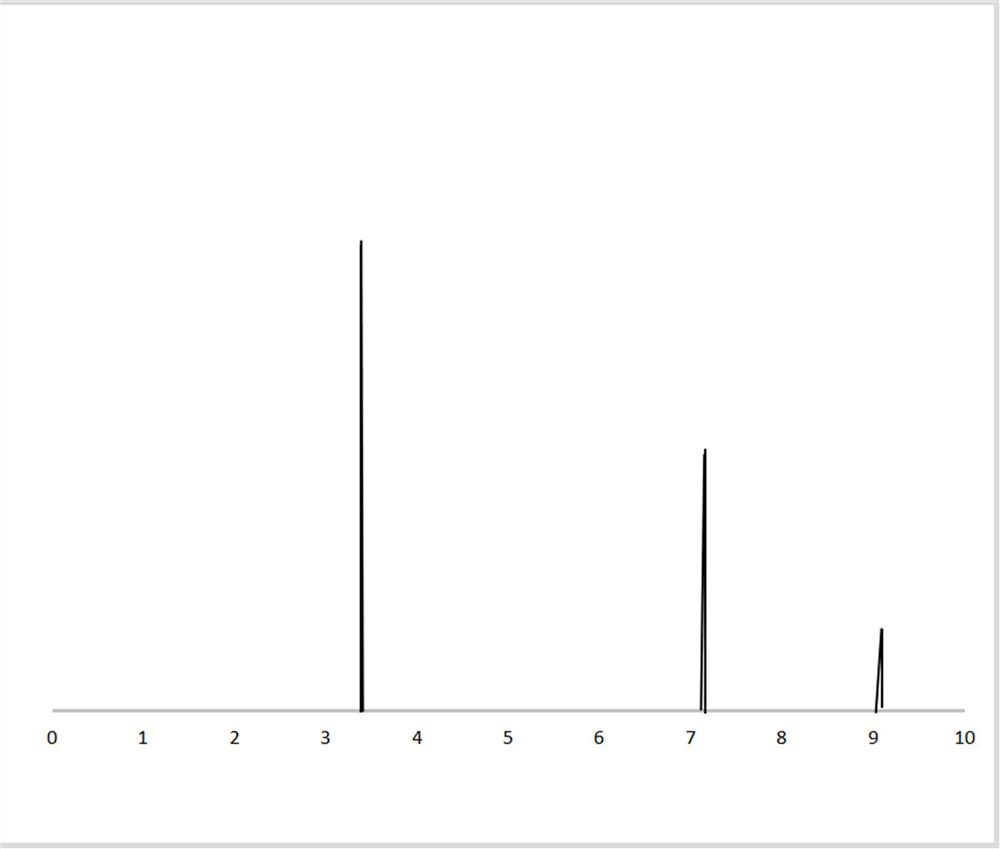

A technology for chloroacetaldehyde oxime and acetaldehyde oxime is applied in the field of preparation of 1-chloroacetaldoxime, which can solve problems such as poor compatibility, explosion of chlorinated products, influence on the yield of chlorination reaction, etc., so as to ensure efficiency and improve yield. The effect of rate and product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

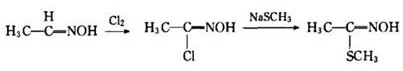

[0039] A method for preparing 1-chloroacetaldoxime, is characterized in that comprising the following steps:

[0040] Put 40g of acetaldehyde oxime into the chlorination kettle after metering, add 150g of chlorinating agent into the chlorination kettle after metering, cool the inside of the kettle with frozen brine, and keep it warm for a certain period of time. At this time, the solution gradually changes from colorless to transparent. Light green, then turn to sea blue, the obtained sea blue transparent solution is 1-chloroacetaldoxime;

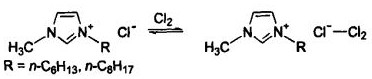

[0041] Described chlorinating agent is polychlorinated chlorine addition ionic liquid, and its preparation scheme is as follows:

[0042] S1: Mercapto-Michael addition reaction: under nitrogen atmosphere, add solvent to polytetrafluoroethylene reaction vessel, then add 30g 1-allyl-3-ethylimidazolium chloride salt, stir and add 2g catalyst, then add 20g ( 2-mercaptoethyl)trimethylammonium chloride, stirred and reacted for a certain period o...

Embodiment 2

[0051] A method for preparing 1-chloroacetaldoxime, is characterized in that comprising the following steps:

[0052] Put 45g of acetaldehyde oxime into the chlorination kettle after metering, add 160g of chlorinating agent into the chlorination kettle after metering, cool down the inside of the kettle with frozen brine, and keep it warm for a certain period of time. At this time, the solution gradually changes from colorless to transparent. Light green, then turn to sea blue, the obtained sea blue transparent solution is 1-chloroacetaldoxime;

[0053] Described chlorinating agent is polychlorinated chlorine addition ionic liquid, and its preparation scheme is as follows:

[0054] S1: Mercapto-Michael addition reaction: under nitrogen atmosphere, add solvent to polytetrafluoroethylene reaction vessel, then add 35g 1-allyl-3-ethylimidazolium chloride salt, stir and add 2g catalyst, then add 22g ( 2-mercaptoethyl)trimethylammonium chloride, stirred and reacted for a certain per...

Embodiment 3

[0063] A method for preparing 1-chloroacetaldoxime, is characterized in that comprising the following steps:

[0064] Put 50g of acetaldehyde oxime into the chlorination kettle after metering, add 170g of chlorinating agent into the chlorination kettle after metering, cool the inside of the kettle by passing frozen brine, and keep it warm for a certain period of time. At this time, the solution gradually changes from colorless to transparent. Light green, then turn to sea blue, the obtained sea blue transparent solution is 1-chloroacetaldoxime;

[0065] Described chlorinating agent is polychlorinated chlorine addition ionic liquid, and its preparation scheme is as follows:

[0066] S1: Mercapto-Michael addition reaction: under nitrogen atmosphere, add solvent to polytetrafluoroethylene reaction vessel, then add 40g 1-allyl-3-ethylimidazolium chloride salt, stir and add 3g catalyst, then add 24g ( 2-mercaptoethyl)trimethylammonium chloride, stirred and reacted for a certain pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com