Preparation method of semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device preparation, can solve the problems of reducing the breakdown resistance of semiconductor devices, reducing the gate oxide layer, and damaging the gate oxide layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

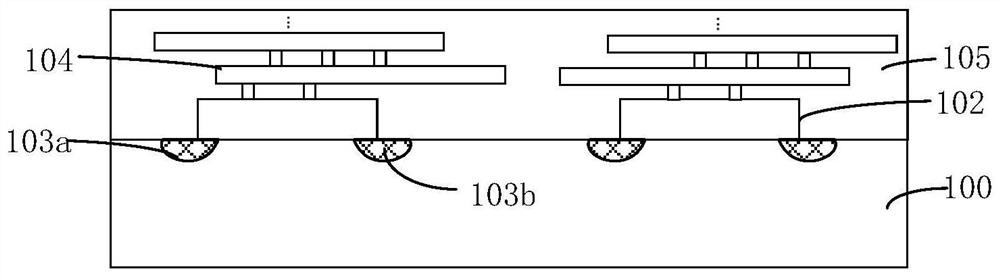

[0028] Figure 1~3 It is a structural schematic diagram corresponding to corresponding steps of a method for preparing a semiconductor device, such as figure 1 As shown, a substrate 100 is provided, and a plurality of gate structures 102 arranged in an array are formed on the substrate 100, and an active region 103a and a drain region 103b are formed in the substrate 100 on both sides of the gate structure 102; A first dielectric layer 105 is formed on the substrate 100, the first dielectric layer 105 covers the substrate 100 and the gate structure 102, and the first dielectric layer 105 has a plurality of stacked metal interconnections An interconnection layer 104, the metal interconnection layer 104 is electrically connected to at least one of the gate structure 102, the source region 103a or the drain region 103b.

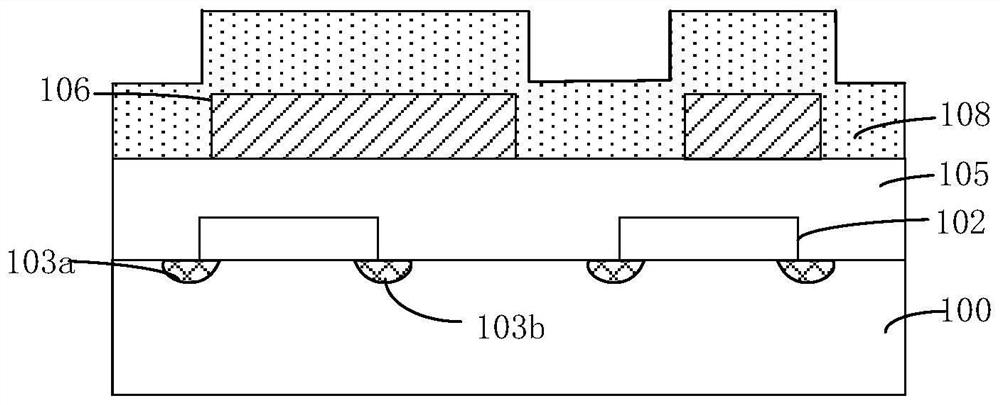

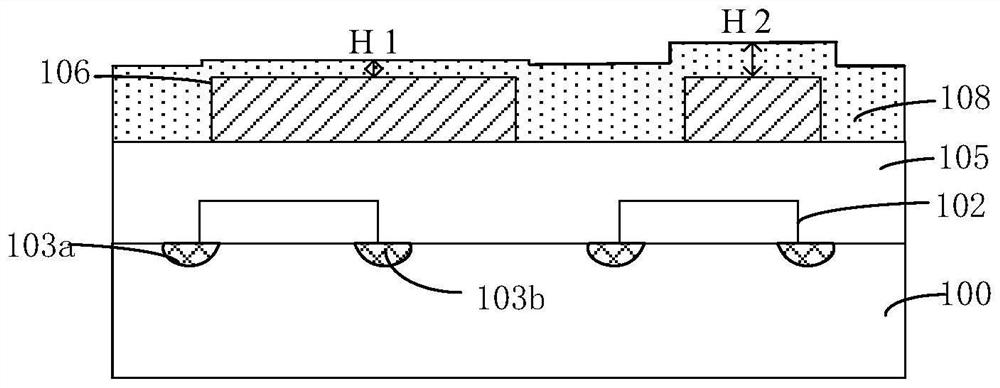

[0029] Such as figure 2 As shown, a patterned top metal layer 106 is formed on the first dielectric layer 105, and the top metal layer 106 communicates with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com