Rotor assembly, motor and vehicle

A rotor and assembly technology, applied in the field of vehicles, can solve the problems of inability to meet high-performance motors, low cooling and lubrication efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions herein will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific embodiments described here are only used for explaining the text, rather than limiting the text.

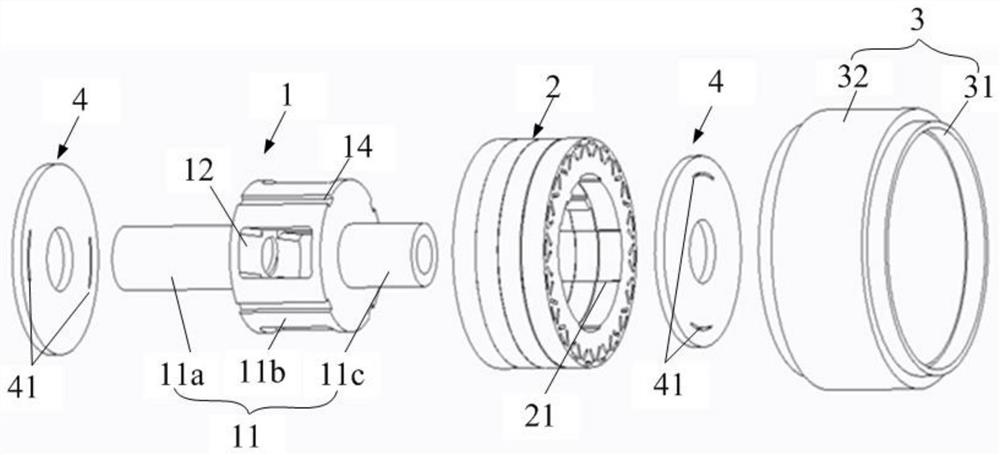

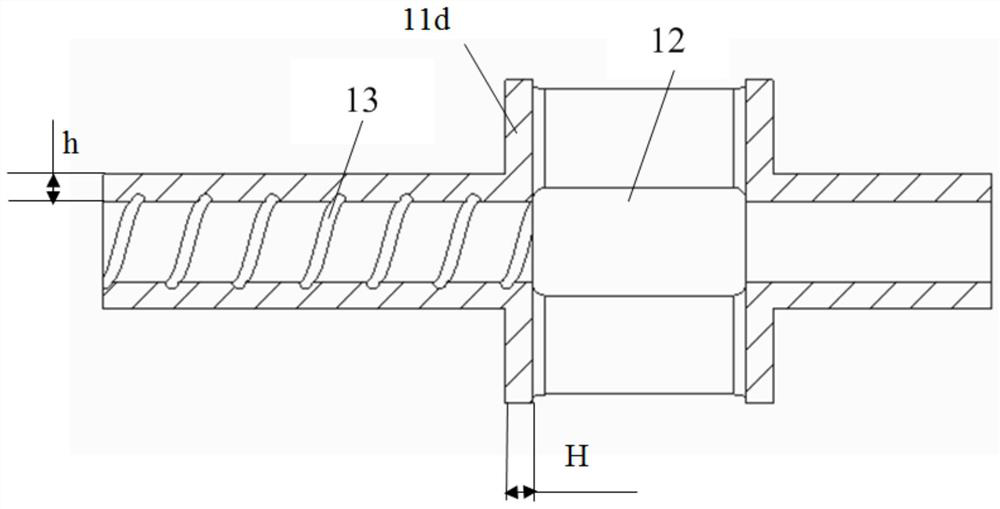

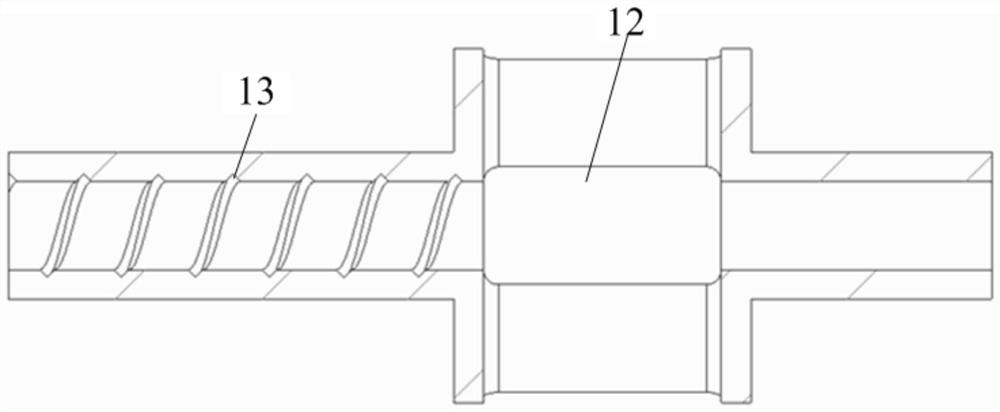

[0041] In one embodiment of this application, as Figure 1 to Figure 4 As shown, a rotor assembly is provided. The rotor assembly includes a rotor core 2 and a rotor shaft 1 , and the rotor core 2 is sleeved on the outer periphery of the rotor shaft 1 . The rotor shaft 1 includes a shaft body 11 and an oil passage groove 12 disposed on the shaft body 11 . The shaft section of the shaft body 11 is provided with an oil inlet channel, and the shaft body 11 can be set as a hollow shaft as a whole. The shaft body 11 can also be a part of the hollow shaft section processed in the partial shaft section of the solid shaft, and the passage in the part of the hollow shaft section is used as an oil inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com