High-temperature gas reverse double-rotation efficient mixer matched with acetylene furnace

A technology of gas mixing and acetylene furnace, applied in chemical instruments and methods, detailed information of chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc., can solve the specific structure and realization method of the mixer without disclosure and other problems, to achieve the effect of improving mixing efficiency, increasing air intake speed, and high mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

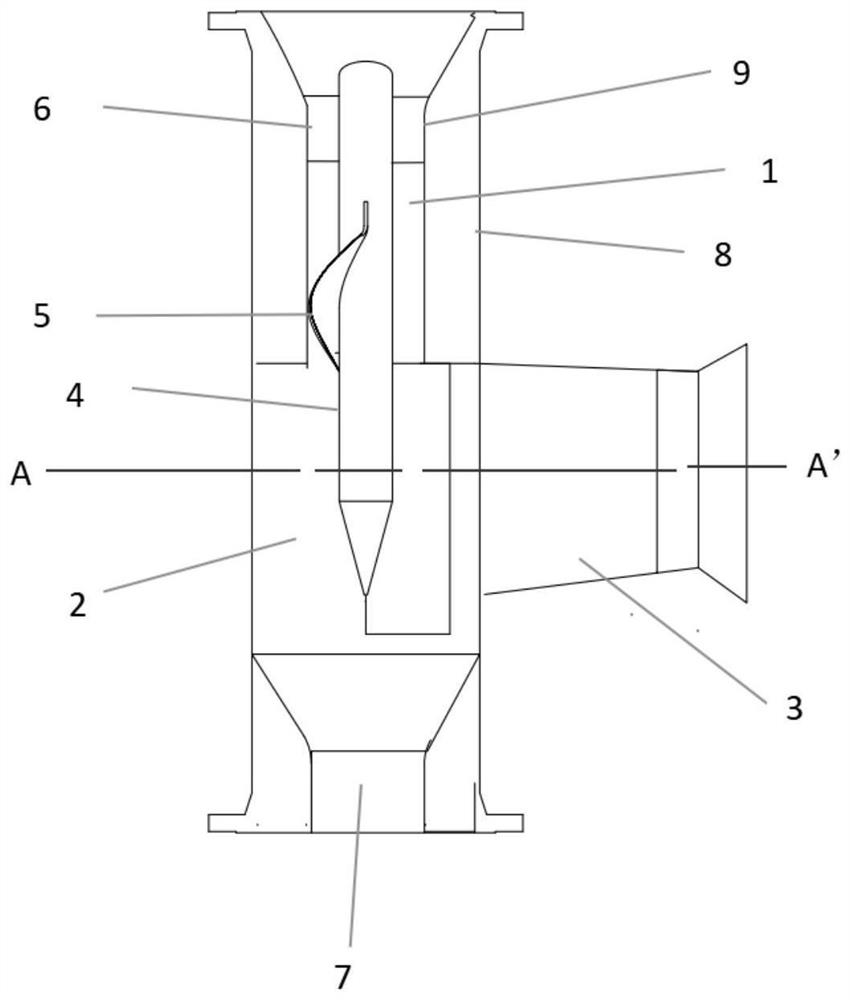

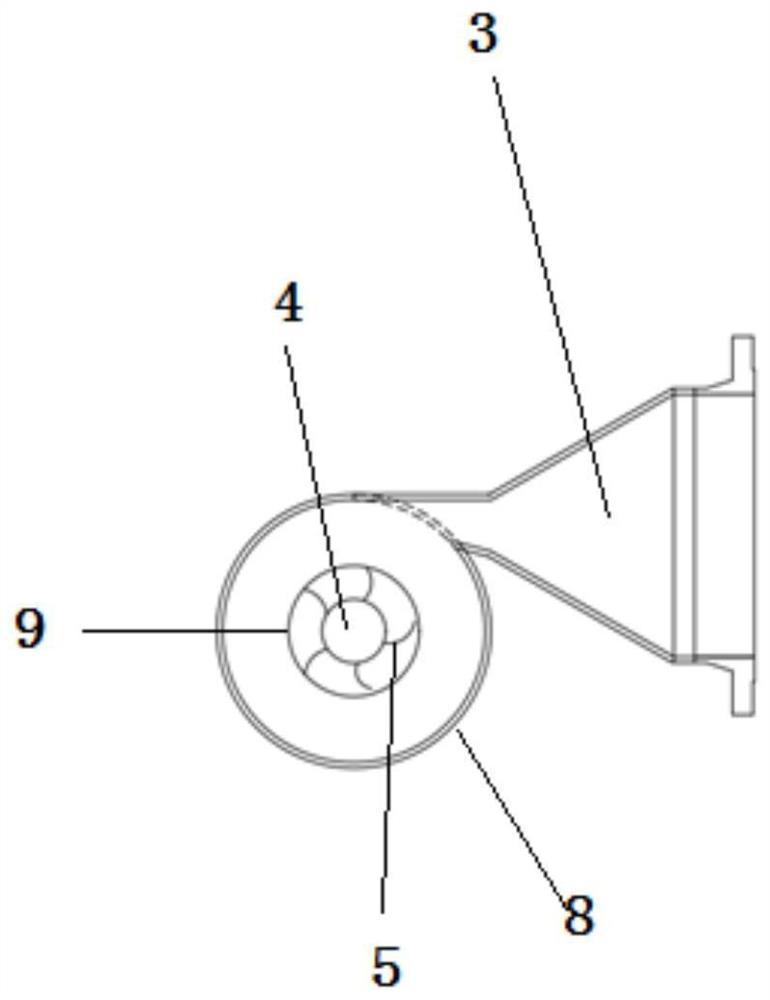

[0040] A gas reverse double-rotation mixer matched with the acetylene furnace, its structure is as follows figure 1 As shown, it includes a first air inlet 1, a gas mixing area 2 and a second air inlet 3; the first air inlet 1 is a port of a shell 8 with a cylindrical structure, and the lower part of the first air inlet 1 The area inside the housing 8 is the gas mixing zone 2, and the first air inlet 1 is used to send the first gas into the gas mixing zone 2; the second air inlet 3 communicates with the housing 8 at the position of the gas mixing zone 2, and uses Then send the second gas into the gas mixing zone 2.

[0041] The specific and preferred structure of the first air inlet 1 is as follows: the center of the first air inlet 1 is provided with an inner sleeve 9, positioning fins 6 and cone columns 4; the inner sleeve 9 has the same outer diameter as the inner diameter of the housing 8 1. The inner diameter is a funnel-shaped closed structure, which is arranged in the ...

Embodiment 2

[0046] A raw material gas mixing process in the process of producing acetylene from natural gas, it uses the gas inverse double-rotation mixer matched with the acetylene furnace in embodiment 1, comprising the following steps:

[0047] Send one of oxygen or hydrocarbon gas into the inner sleeve 9 from the mouth of the first air inlet 1;

[0048] The other one of oxygen or hydrocarbon gas is sent into the shell from the mouth of the second air inlet 3;

[0049] The two gases are mixed in the gas mixing zone 2 .

[0050] Preferably, the gas velocity entering the gas mixing area 2 from the first air inlet 1 is 120-320m / s; the gas velocity entering the gas mixing area 2 from the first air inlet 1 is 120-280m / s; The mixing time of the mixing zone is 0.001-0.01S, and then enters the acetylene reaction furnace from the exhaust part 7; the gas entering the gas mixing zone in the shell 8 from the mouth of the second air inlet 3 is natural gas raw material gas; the gas mixing The temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com