High-permeability intercalation toughening material and preparation method thereof

A high-permeability and permeable layer technology, applied in the field of high-permeability intercalation toughening materials and their preparation, can solve the problem of not being able to have high permeability and high toughness at the same time, and improve the interlayer damage resistance and material length. Unlimited, the effect of reducing the difficulty of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of a high-permeability intercalated toughening material composited by polyurethane and aramid fiber comprises the following steps:

[0034] Step 1, prepare a layer of fiber permeable layer, the surface density of the fiber permeable layer is 10g / m 2 , the fiber permeable layer is a chopped fiber mat, made of aramid fiber, and the fiber length in the chopped fiber mat is 6mm;

[0035] Step 2, put the polyurethane pellets into the melting equipment, and melt them to a fluid at a high temperature of 220°C;

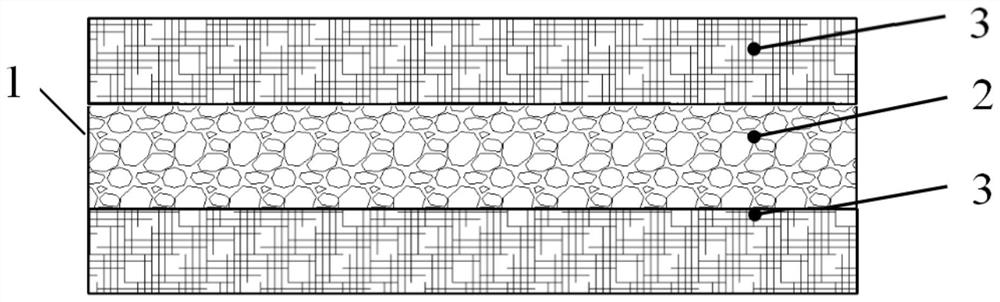

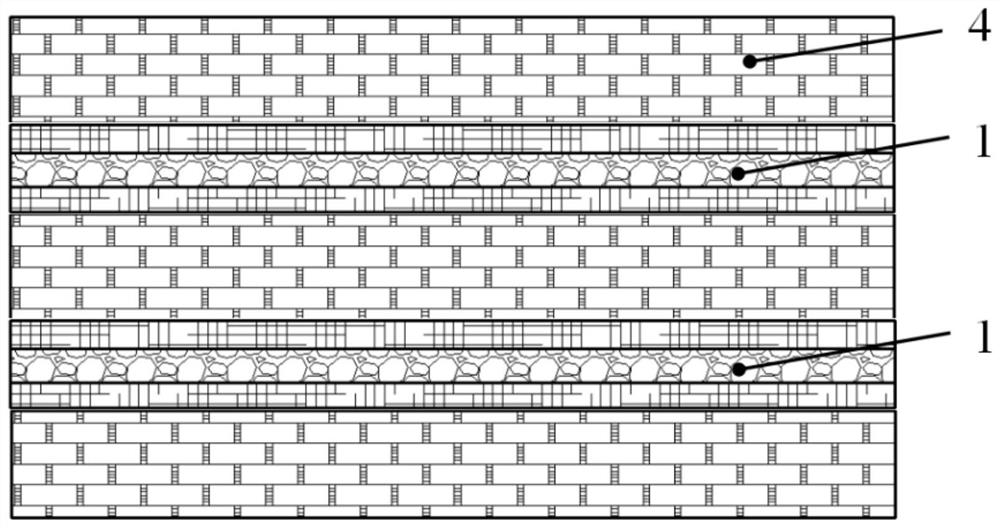

[0036] Step 3, spray the melted polyurethane through a high-speed hot air nozzle, and the surface density of the fiber permeable layer prepared in step 1 is 40g / m 2 The uniform network-shaped toughening layer is conveyed to the position of the paving roller by the roller; the viscous filamentous toughening material in the molten state only bonds the floating fibers on the surface of the chopped fiber permeable layer, and will not infiltrate into the pe...

Embodiment 2

[0040] The preparation of a high-permeability intercalation toughening material composited by polyamide and glass fiber comprises the following steps:

[0041] Step 1, prepare one layer of fiber permeable layer, the surface density of fiber permeable layer is 8g / m 2 , the fiber permeable layer is chopped fiber mat, made of glass fiber, the glass fiber length in the chopped fiber mat is 5mm;

[0042]Step 2, put the polyamide pellets into the melting equipment, and melt them to a fluid at a high temperature of 250°C;

[0043] Step 3, the melted polyamide is sprayed through a high-speed hot air nozzle, and the surface density of the fiber permeable layer prepared in step 1 is 60g / m 2 The mesh toughening layer is conveyed to the position of the laying roller through the roll roller;

[0044] Step 4, laying and bonding a layer of chopped glass fiber permeable layer on the surface of the uncooled network toughening layer, and after cooling down on the production line, a high-stren...

Embodiment 3

[0047] The preparation of a high-permeability intercalation toughening material composited by polyethersulfone and carbon fiber comprises the following steps:

[0048] Step 1, prepare a layer of fiber permeable layer, the surface density of the fiber permeable layer is 10g / m 2 , the fiber permeation layer is chopped fiber mat, made of carbon fiber, the length of carbon fiber in the chopped fiber mat is 6mm;

[0049] Step 2, put the polyethersulfone pellets into a melting device, and melt it to a fluid at a high temperature of 400°C;

[0050] Step 3, spray the melted polyethersulfone through a high-speed hot air nozzle, and spray on the upper surface of the fiber permeable layer prepared in step 1. The surface density is 80g / m 2 The mesh toughening layer is conveyed to the position of the laying roller through the roll roller;

[0051] Step 4: Lay and bond a layer of chopped carbon fiber permeable layer on the surface of the uncooled network toughening layer. After cooling do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com