High-strength tear-resistant fabric structure

A tear-resistant, high-strength technology, applied in the field of clothing fabrics, can solve the problems of poor breathability and water absorption, low comfort, and low flame retardancy of polyamide fibers, and achieves increased thermal performance, improved flame retardancy, and excellent flame retardancy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

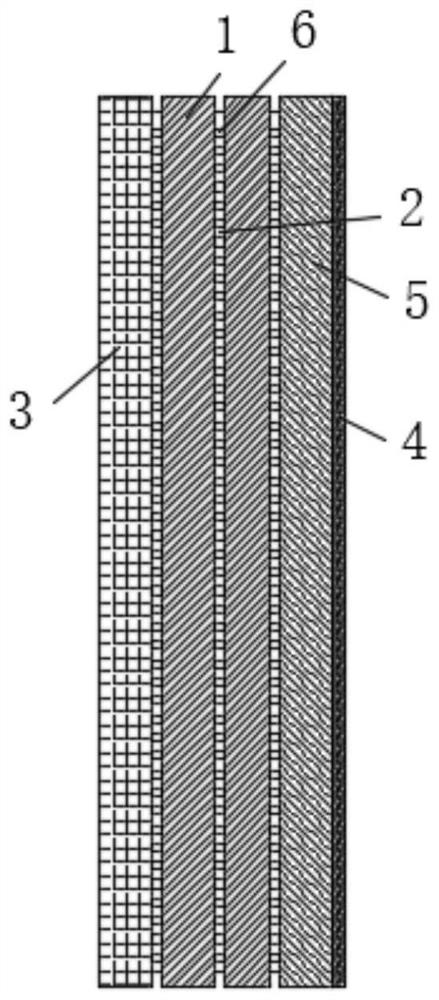

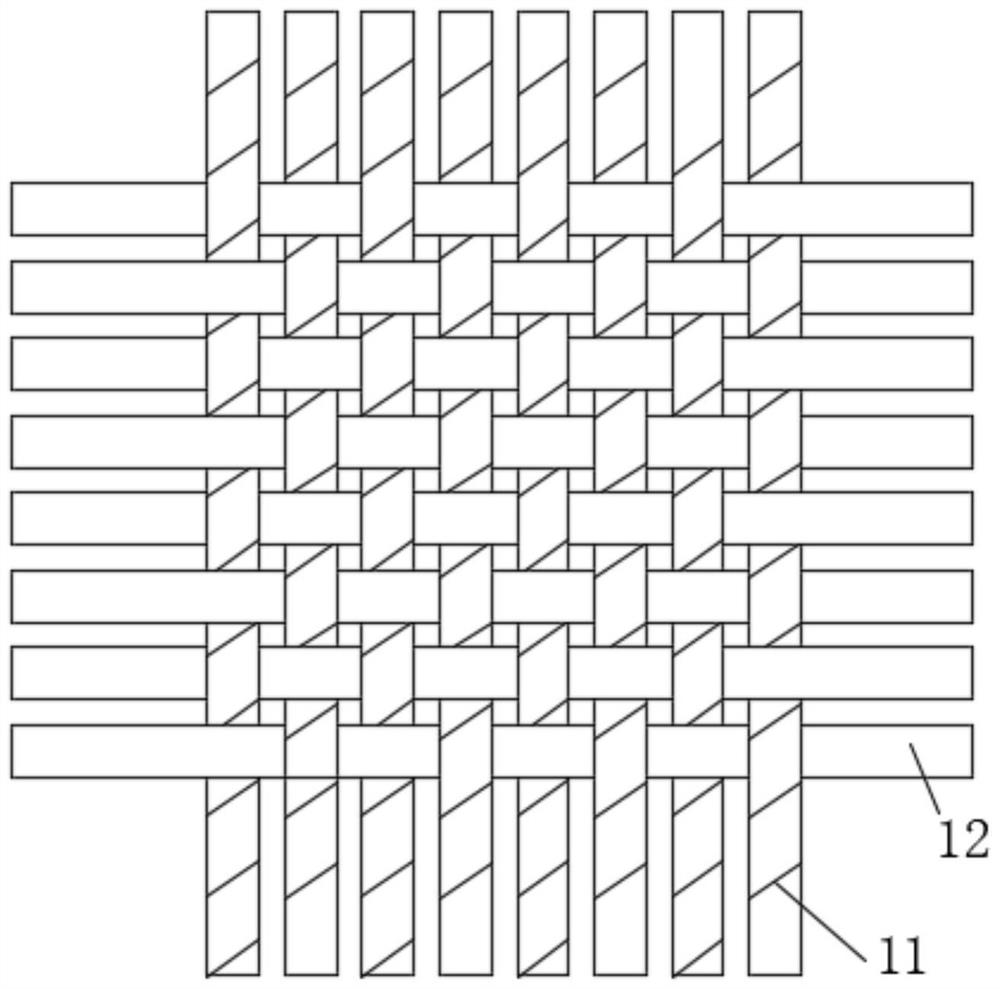

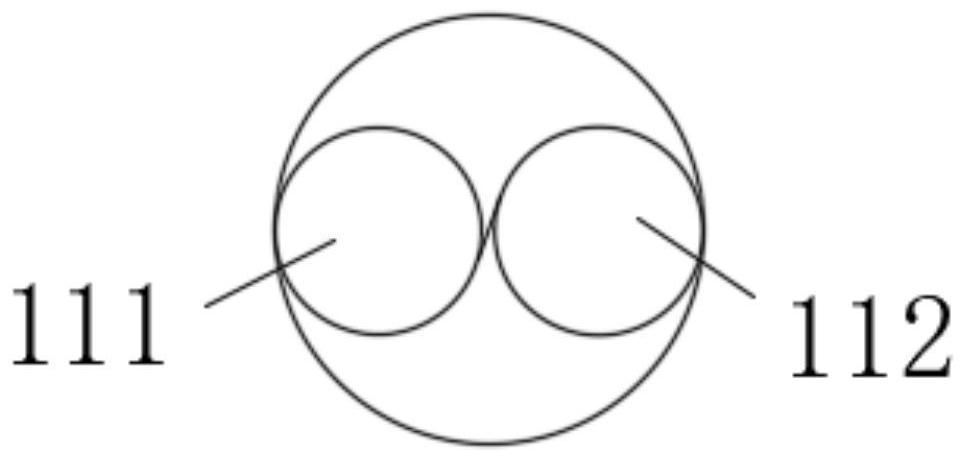

[0024] Such as Figure 1-3 As shown, a high-strength tear-resistant fabric structure includes a base fabric. The base fabric is obtained by thermocompression bonding of two layers of base fabric 1 through an adhesive layer 2. The base fabric 1 uses the base yarn 11 as a warp and is flame-retardant The polyester yarn 12 is formed by weaving interlaced weft threads, the warps of the two layers of basic fabric 1 are perpendicular to each other, and the basic yarn 11 is formed by parallel twisting of polyamide fibers 111 and polyvinyl formal fibers 112;

[0025] The inner and outer sides of the base fabric are respectively bonded with the inner layer fabric 5 and the surface layer fabric 3 through the adhesive layer 2 to obtain a tear-resistant fabric. The inner surface of the inner layer fabric 5 is coated with a heat reflective layer 4, and the adhesive layer 2 is distributed with Uneven ventilation holes6.

[0026] Polyamide fiber 111 provides high tear resistance and pull res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com