Graphene and preparation method thereof

A technology of graphene and graphite powder, which is applied in the field of graphene and its preparation, can solve the problems of graphene product ratio to be improved and low grinding disc efficiency, and achieve the effects of improving stripping efficiency, reducing wear and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

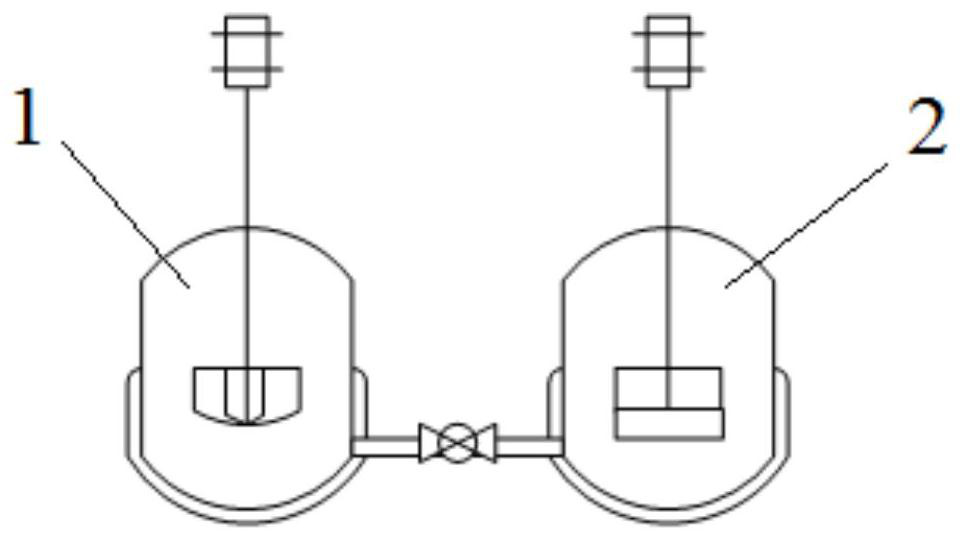

[0061] use figure 1 The shown kettle 1 (emulsifying machine) and kettle 2 (with a grinding disc and a closed device inside) are connected in series, and 100 g of 32-mesh flake graphite powder (purchased from Qingdao Jintao Graphite Co., Ltd.) is ultrasonically cleaned (washed once with water, ethanol wash 2 times) to remove heterogeneous substances and impurity elements, then place the flake graphite in kettle 1, seal kettle 1 well, heat the temperature in kettle 1 to 55°C, and pump 2.5kg of CO 2 Raise the pressure in kettle 1 to 12.0 MPa, set the stirring speed of kettle 1 at 2800 rpm, and stir for 4 hours. Use the pressure difference to transfer the mixture in kettle 1 to kettle 2, control the temperature in kettle 2 to 55°C, and supplement CO 2 Make the pressure inside the kettle 2 be 12.0 MPa, set the rotational speed of the grinding disc at 1500 rpm, and grind for 8 hours. Then use the pressure difference to transfer the mixture in kettle 2 to kettle 1, control the temp...

Embodiment 2

[0064] Using a device connected in series between kettle 1 (emulsifier) and kettle 2 (with a grinding disc and closed equipment inside), 200 g of 32-mesh flake graphite powder was ultrasonically cleaned (washed once with water, washed twice with ethanol) to remove heterogeneous substances and impurities element, then place the flake graphite in kettle 1, seal kettle 1 well, heat the temperature inside kettle 1 to 40°C, and pump 2.8kg of CO 2 Raise the pressure in Kettle 1 to 10.0 MPa, set the stirring speed of Kettle 1 to 1500 rpm, and stir for 8 hours. Use the pressure difference to transfer the mixture in kettle 1 to kettle 2, control the temperature in kettle 2 to 40°C, and supplement CO 2 Make the pressure in the kettle 2 be 10.0 MPa, set the rotational speed of the grinding disc at 1000 rpm, and grind for 10 hours. Then use the pressure difference to transfer the mixture in kettle 2 to kettle 1, control the temperature in kettle 1 to 40°C, and supplement CO 2 Make the...

Embodiment 3

[0067] Using a device connected in series between kettle 1 (emulsifier) and kettle 2 (with a grinding disc inside and a closed device), 400 g of 32-mesh flake graphite powder was ultrasonically cleaned (washed once with water, washed twice with ethanol) to remove heterogeneous substances and impurities element, then place the flake graphite in kettle 1, seal kettle 1 well, heat the temperature in kettle 1 to 70°C, and pump 2.2kg of CO 2 Raise the pressure in Kettle 1 to 16.0 MPa, set the stirring speed of Kettle 1 to 3500 rpm, and stir for 2 hours. Use the pressure difference to transfer the mixture in kettle 1 to kettle 2, control the temperature in kettle 2 to 70°C, and supplement CO 2 Make the pressure inside the kettle 2 be 16.0 MPa, set the rotational speed of the grinding disc at 2000 rpm, and grind for 4 hours. Then use the pressure difference to transfer the mixture in kettle 2 to kettle 1, control the temperature in kettle 1 to 70°C, and supplement CO 2 Make the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com