Hydrofining method of crude 2, 6-naphthalic acid

A naphthalene dicarboxylic acid, hydrogenation refining technology, applied in the direction of carboxylate preparation, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of high naphthalene production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

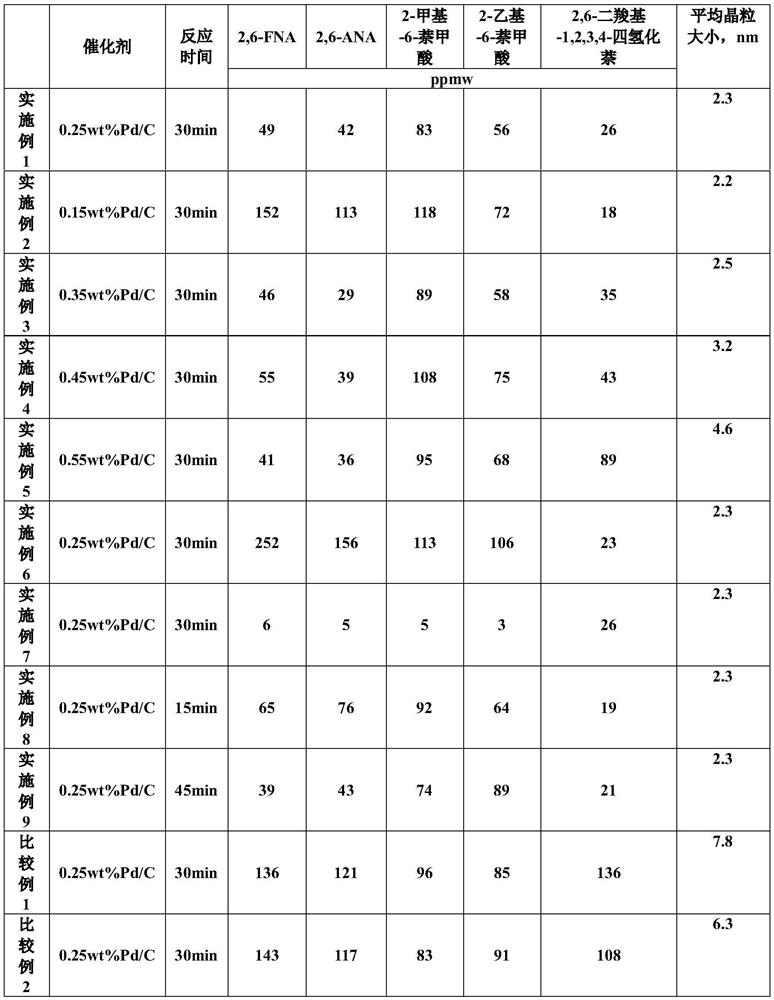

Examples

Embodiment 1

[0033] 1. Preparation of crude 2,6-naphthalenedicarboxylic acid samples

[0034] 311.25g Co(OAc) 2 ·4H 2 O, 306.25g Mn(OAc) 2 ·4H 2 O, 297.5g KBr, 367.5g CH 3 COOK and 7760g acetic acid are mixed and added in the reactor, then open and stir and be warming up to 185 ℃, the reactor pressure is controlled at 2.75MPa, 1000g 2,6-diisopropylnaphthalene is first warming up to molten state, then with 6g / min The speed enters the reaction kettle, and at the same time, a sufficient amount of air is introduced for the reaction. After the feeding is completed, the reaction temperature and pressure are maintained to continue the reaction for 1 h. Filter, and respectively adopt 60 ℃ of acetic acid washing, 80 ℃ of water washing, the consumption of washing acetic acid is 1000g, and the consumption of washing water is 1000g, after sampling and drying, analyze the impurities 2-formyl-6-naphthoic acid and 2-acetyl- 6-naphthoic acid content. After analysis, the content of 2-formyl-6-naphtho...

Embodiment 2

[0041] 1. Preparation of crude 2,6-naphthalenedicarboxylic acid samples

[0042] 311.25g Co(OAc) 2 ·4H 2 O, 306.25g Mn(OAc) 2 ·4H 2 O, 297.5g KBr, 367.5g CH 3 COOK and 7760g acetic acid are mixed and added in the reactor, then open and stir and be warming up to 185 ℃, the reactor pressure is controlled at 2.75MPa, 1000g 2,6-diisopropylnaphthalene is first warming up to molten state, then with 6g / min The rate enters the reaction kettle, and at the same time, a sufficient amount of air is introduced for the reaction. After the feeding is completed, the reaction temperature and pressure are maintained to continue the reaction for 1 h. Filter, and adopt 60 ℃ of acetic acid washing respectively, 80 ℃ of water washing, the consumption of washing acetic acid is 1000g, the consumption of washing water is 1000g, after sampling and drying, analyze the impurities 2-formyl-6-naphthoic acid and 2-acetyl- 6-naphthoic acid content. After analysis, the content of 2-formyl-6-naphthoic ac...

Embodiment 3

[0049] 1. Preparation of crude 2,6-naphthalenedicarboxylic acid samples

[0050] 311.25g Co(OAc) 2 ·4H 2 O, 306.25g Mn(OAc) 2 ·4H 2 O, 297.5g KBr, 367.5g CH 3 COOK and 7760g acetic acid are mixed and added in the reactor, then open and stir and be warming up to 185 ℃, the reactor pressure is controlled at 2.75MPa, 1000g 2,6-diisopropylnaphthalene is first warming up to molten state, then with 6g / min The rate enters the reaction kettle, and at the same time, a sufficient amount of air is introduced for the reaction. After the feeding is completed, the reaction temperature and pressure are maintained to continue the reaction for 1 h. Filter, and adopt 60 ℃ of acetic acid washing respectively, 80 ℃ of water washing, the consumption of washing acetic acid is 1000g, the consumption of washing water is 1000g, after sampling and drying, analyze the impurities 2-formyl-6-naphthoic acid and 2-acetyl- 6-naphthoic acid content. After analysis, the content of 2-formyl-6-naphthoic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com