High-selectivity production process for preparing butanedioic anhydride through maleic anhydride liquid-phase hydrogenation

A maleic anhydride liquid-phase method and succinic anhydride technology, applied in the direction of organic chemistry, can solve the problem of succinic anhydride not being able to balance selectivity and large-scale industrial production, and achieve increased heat capacity, small filling volume, and reduced temperature rise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

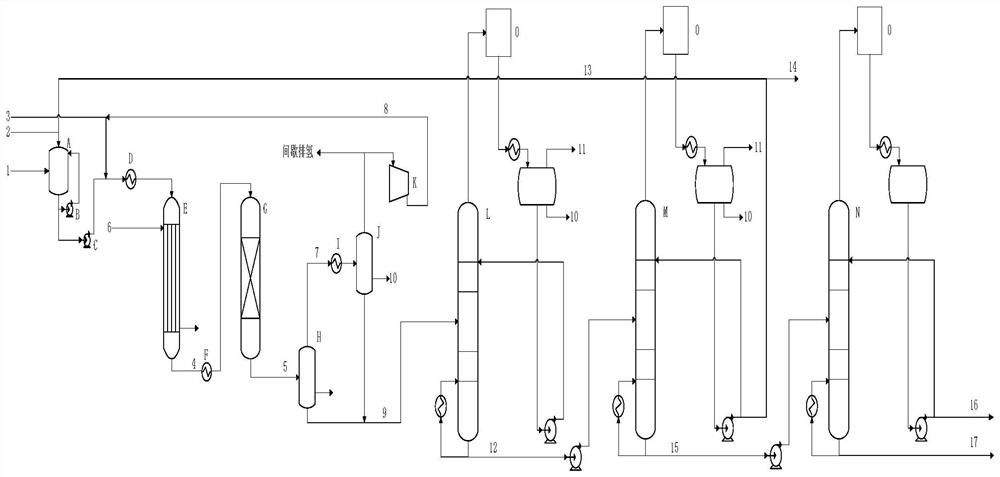

Image

Examples

Embodiment 1

[0034] 5. 15t / h raw material maleic anhydride 1, supplemented butyrolactone solvent 2, and circulating butyrolactone solvent 13 are mixed in the mixing tank A at a volume ratio of 1:10, and a circulating pump B is installed at the bottom of the mixing tank A to continuously Feed liquid is pumped back to the top of mixing tank A. The mixed material liquid is pressurized by the raw material pump C and mixed with the new hydrogen 3 and the circulating hydrogen 13 of the 3.5MPaG pipe network outside the boundary. The volume ratio of maleic anhydride to hydrogen is 1:2. The temperature of the material in the mixture M is 82°C. The mixed material is cooled to 60°C by the water cooler D, and enters the non-adiabatic reactor E from top to bottom for liquid phase hydrogenation reaction.

[0035] The mixed material enters the non-adiabatic reactor E from top to bottom, the inlet temperature is 60°C, and the operating pressure of the reactor is 3.0MPa. The inner diameter of a single tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com