Combustion device and volatile organic compound treatment method

A technology of combustion device and combustion chamber, which is applied in the direction of combustion method, burner, combustion type, etc., can solve the problem of high energy consumption of regenerative thermal oxidation furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

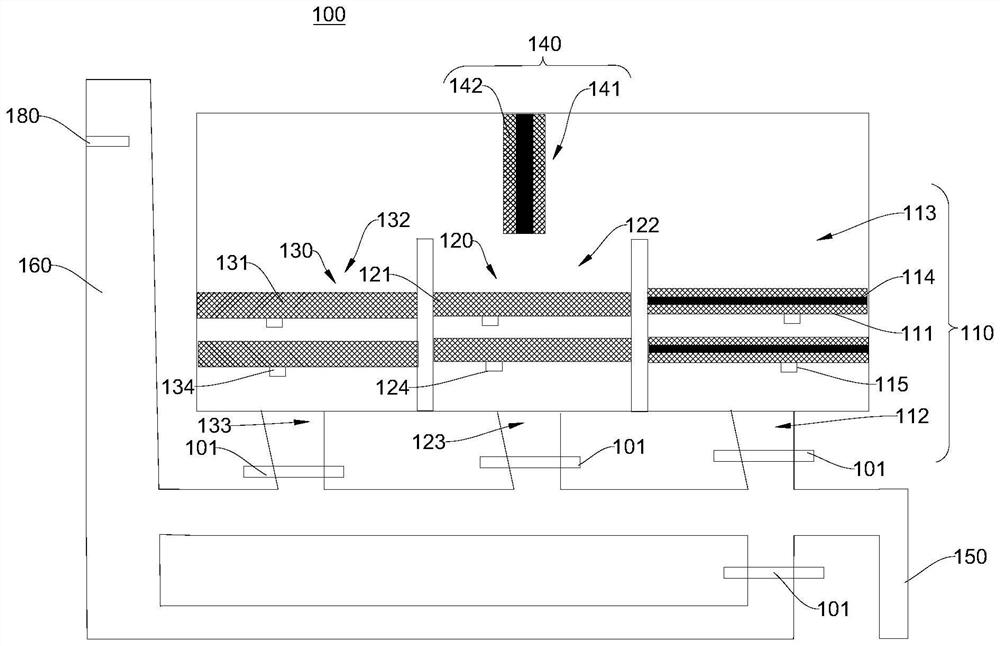

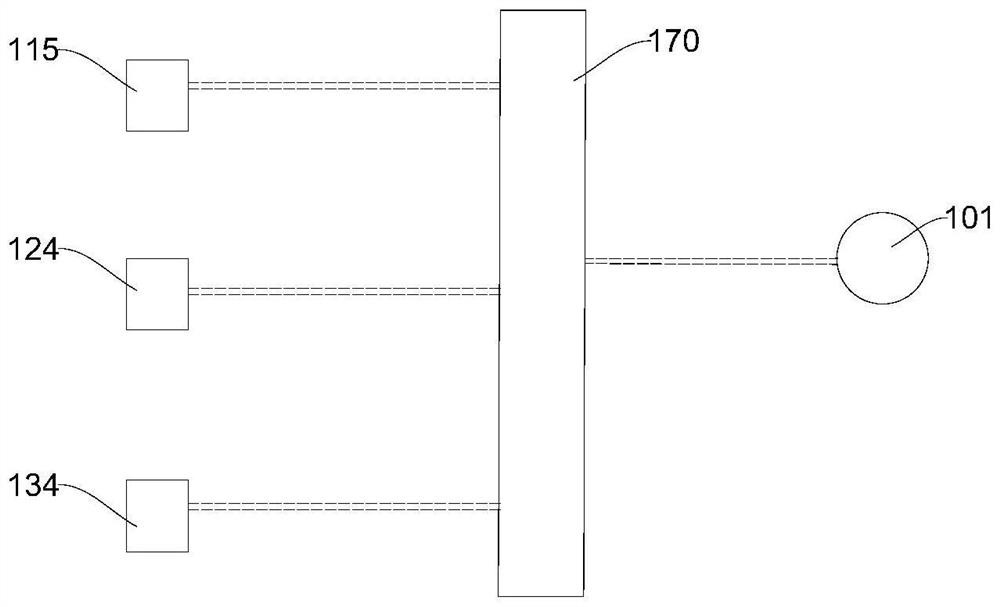

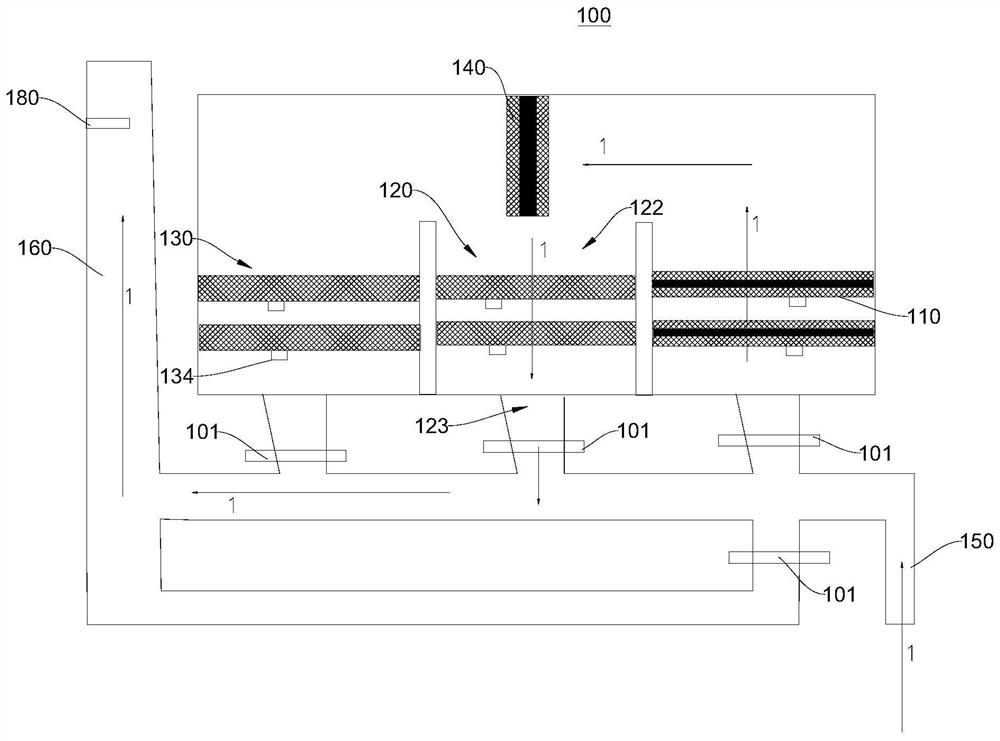

[0039] figure 1 Shows a schematic diagram of the internal structure of the combustion device 100 provided by the embodiment of the present application, please refer to figure 1 , this embodiment provides a combustion device 100, the combustion device 100 includes a first heat exchange assembly 110, a second heat exchange assembly 120, a third heat exchange assembly 130, a combustion assembly 140, an air intake pipe 150 and a flue gas pipe 160; The first heat exchange assembly 110, the second heat exchange assembly 120, and the third heat exchange assembly 130 are all connected to the combustion assembly 140, so that the heat of the combustion assembly 140 can be transferred to the first heat exchange assembly 110, the second heat exchange assembly 120 And the third heat exchanging component 130 . The first heat exchange assembly 110, the second heat exchange assembly 120, and the third heat exchange assembly 130 are all connected to the intake pipe 150, and the first heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com