Multifunctional electric four-wheel-drive operation platform

A work platform and multi-functional technology, applied in electric vehicles, agriculture, vehicle energy storage, etc., can solve the problems of difficult turning, human health hazards, single function, etc., and achieve the effect of convenient operation and walking, and convenient and fast steering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

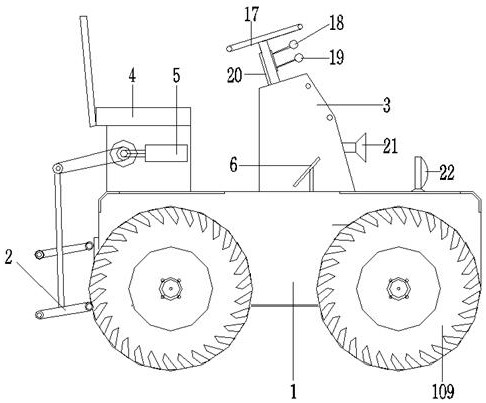

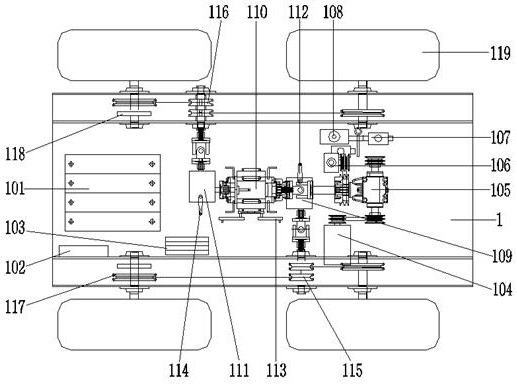

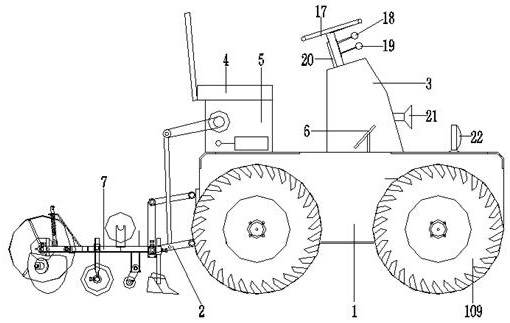

[0036] Example 1 as image 3 , 4 , 5, 6, 7, according to the needs of field operations, the film spreading mechanism 7, the seeding mechanism 8, the spraying mechanism 9, the fertilizer spreading mechanism 10, and the weeding mechanism 11 are respectively connected to the three-point suspension mechanism 2 through the mounting frame, and the hydraulic pressure is used to After the oil cylinder 5 is connected to the three-point suspension mechanism 2 through the lifting link, the assembly work of the group of electric film spreading machine, electric seeder, electric spraying machine, electric fertilizer spreader, and electric herbicide is completed. When working, the operator passes Operate the control pedal 6 and the shifting operating handle 18, and control the motor 104 to work through the controller 103. The kinetic energy is transmitted through the right-angle gear box 105, and the left side unilaterally locks the steering gearbox 109, the reverse gear conversion gear box...

Embodiment 2

[0037] Example 2 as Figure 8 , 9 , 10. According to the needs of mechanized operations, fix the loading and unloading linkage arm 12 on the connecting arm fixing table 3, then install the telescopic oil cylinder 13 on the loading and unloading linkage arm 12, and connect the telescopic oil cylinder 13 with the controller 103, and then separate the loading and unloading The end of the linkage arm 12 is connected to the fork piece 14, the shovel head piece 15, and the head piece 16 according to the requirements, that is, the assembly of the electric forklift, electric forklift or electric grass catcher is completed. Control the telescopic oil cylinder 13 to make the loading and unloading linkage arm 12 rise to walk. During the walking process, the operator controls the motor 104 to work through the controller 103 by operating the control pedal 6 and the gear shifting handle 18. After the side unilateral lock steering gearbox 109, the reverse gear conversion gear box 110, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com