Hand sanitizer powder as well as preparation process and use method thereof

A preparation process and technology of hand sanitizer, applied in the field of hand sanitizer, can solve the problems of reducing carrying volume and weight, liquid hand sanitizer is large in size, and inconvenient to carry, and achieves the effects of rich application forms, simple preparation process, and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

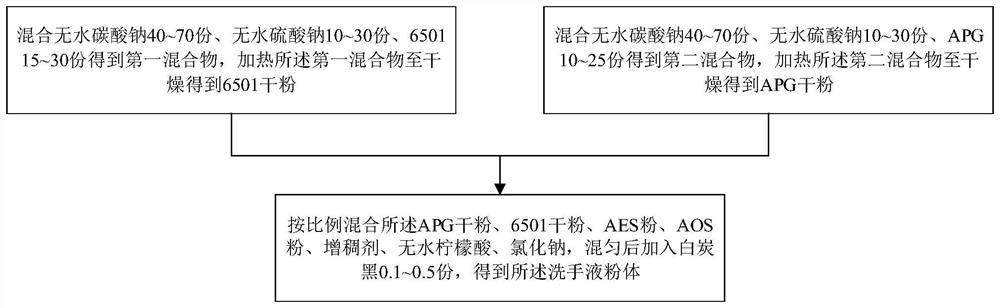

Method used

Image

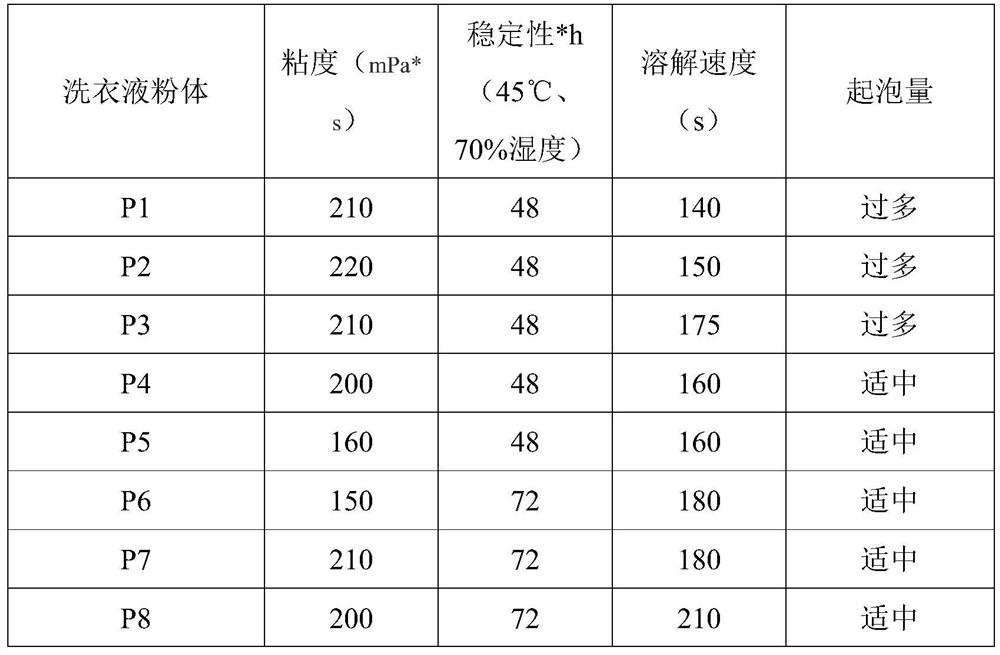

Examples

Embodiment 1

[0042] Weigh 60 parts of anhydrous sodium carbonate, 20 parts of anhydrous sodium sulfate, and 15 parts of 6501. After the three components are mixed uniformly by a mixer, they are heated to dryness to obtain 6501 dry powder. Weigh 60 parts of anhydrous sodium carbonate, 20 parts of anhydrous sodium sulfate, and 20 parts of APG. After the three components are mixed uniformly by a mixer, they are heated to dryness to obtain APG dry powder.

[0043] Mix 20 parts of AES powder, 20 parts of AOS powder, 5 parts of SNF-SH, 10 parts of 6501 dry powder, 15 parts of APG dry powder, 20 parts of anhydrous citric acid, and 45 parts of sodium chloride to obtain hand sanitizer powder P1.

Embodiment 2

[0045] Weigh 60 parts of anhydrous sodium carbonate, 20 parts of anhydrous sodium sulfate, and 15 parts of 6501. After the three components are mixed uniformly by a mixer, they are heated to dryness to obtain 6501 dry powder. Weigh 60 parts of anhydrous sodium carbonate, 20 parts of anhydrous sodium sulfate, and 20 parts of APG. After the three components are mixed uniformly by a mixer, they are heated to dryness to obtain APG dry powder.

[0046] Mix 20 parts of AES powder, 20 parts of AOS powder, 5 parts of 40-mesh CMC, 10 parts of 6501 dry powder, 15 parts of APG dry powder, 20 parts of anhydrous citric acid, and 45 parts of sodium chloride to obtain hand sanitizer powder P2.

Embodiment 3

[0048] Weigh 60 parts of anhydrous sodium carbonate, 20 parts of anhydrous sodium sulfate, and 15 parts of 6501. After the three components are mixed uniformly by a mixer, they are heated to dryness to obtain 6501 dry powder. Weigh 60 parts of anhydrous sodium carbonate, 20 parts of anhydrous sodium sulfate, and 20 parts of APG. After the three components are mixed uniformly by a mixer, they are heated to dryness to obtain APG dry powder.

[0049] Mix 15 parts of AES powder, 20 parts of AOS powder, 5 parts of 40-mesh CMC, 7 parts of 6501 dry powder, 15 parts of APG dry powder, 20 parts of anhydrous citric acid, and 45 parts of sodium chloride to obtain hand sanitizer powder P3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com