Drum-type cleaning alloy tooth polishing machine and polishing method thereof

An alloy tooth and drum type technology is applied in the field of alloy tooth polishing, which can solve the problems of surface corrosion of alloy teeth, affecting the service life of alloy teeth, affecting the geometric strength of alloy teeth, etc., so as to reduce labor intensity, improve service life and facilitate feeding. and the effect of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

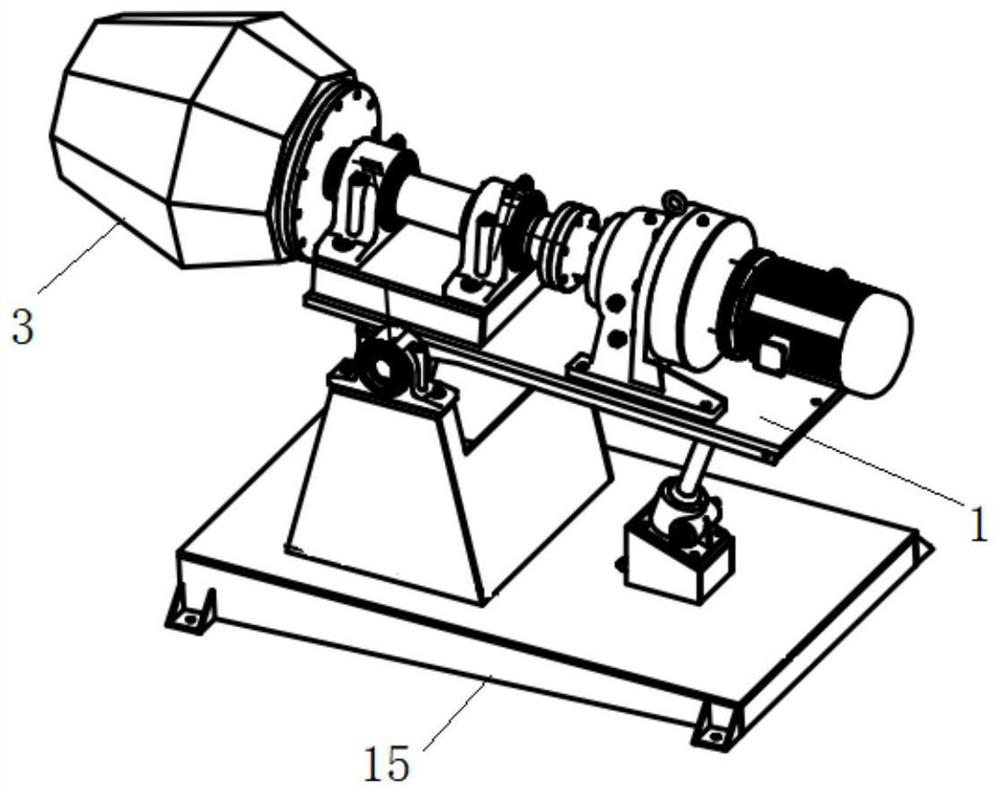

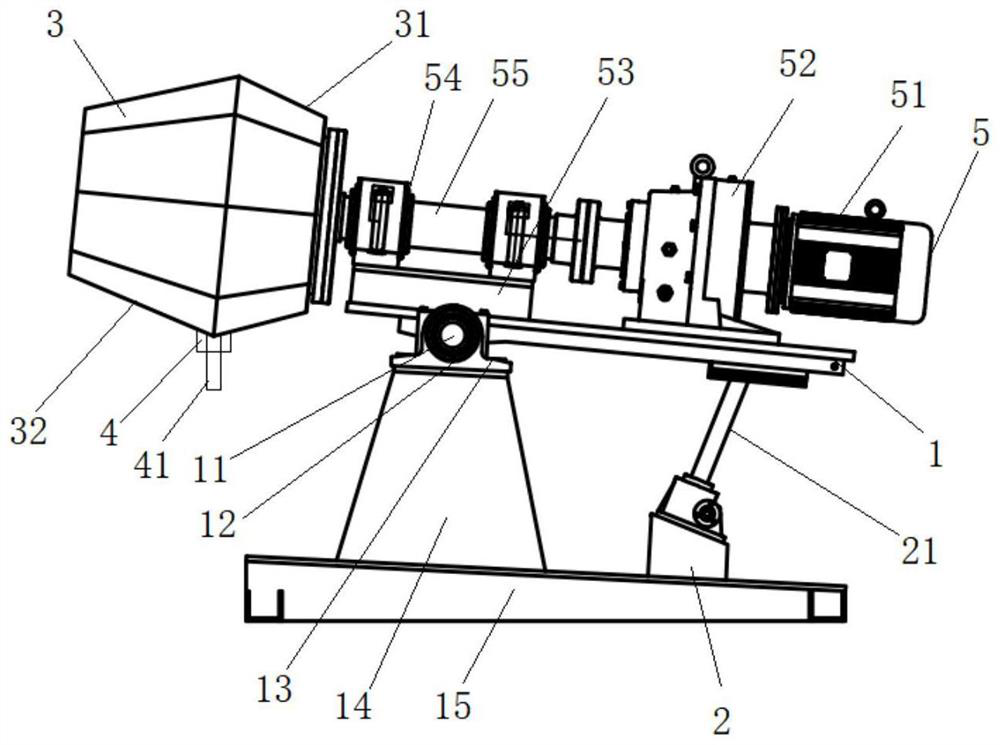

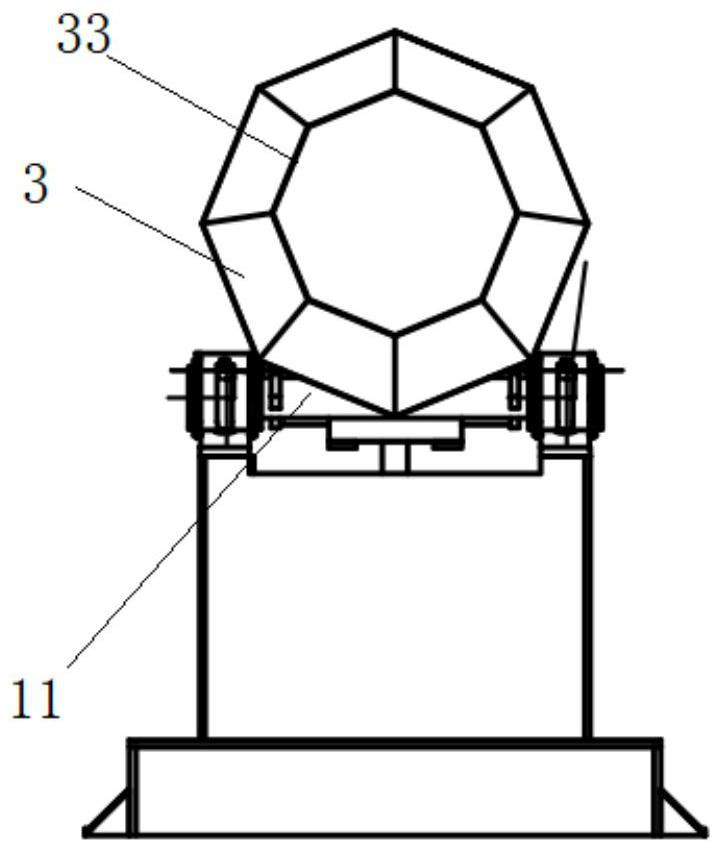

[0029] refer to Figure 1-3 As shown, this embodiment is a drum-type cleaning alloy tooth polishing machine, including a support plate 1, a first drive device 2 that drives the support plate 1 to tilt and rotate relative to the horizontal direction, and a rotating device that is horizontally arranged on the support plate 1. The cleaning drum 3 and the drainage assembly 4 arranged on the outer wall of the cleaning drum 3; the cleaning drum 3 includes a first cylinder 31 close to the driving end, a second cylinder 32 connecting the first cylinder 31 and forming a washing chamber, and the cleaning drum 3 is coated with a resin coating in the inner wall.

[0030] The support plate 1 is a rectangular plate body, the bottom of the support plate 1 is provided with a bearing mandrel 11 arranged in the horizontal direction, the two sides below the support plate 1 are symmetrically provided with bearing sleeves 12 sleeved on the bearing mandrel 11, and the bearing sleeves 12 It can be ...

Embodiment 2

[0036] The present embodiment is a drum-type cleaning alloy tooth polishing method, comprising the following steps:

[0037] Grinding the alloy teeth by machining with a centerless grinder;

[0038] The polished batches of alloy teeth are put into the cleaning drum 3, an appropriate amount is located in the washing chamber, and the support plate 1 is in a horizontal state, so that the batches of alloy teeth can enter through the feeding port 33;

[0039] The control panel sets the operating parameters of the cleaning drum 3, starts the feeding mode, and the first driving device 2 controls the tilting state of the support plate 1, so that the feeding port 33 is set upward;

[0040] Clean water is injected into the cleaning drum 3, and the level of the clean water is lower than the feeding port 33;

[0041] The control panel starts the second driving device 5 according to the set parameters, starts the polishing mode, and the cleaning drum 3 rotates to perform stirring and poli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com