Continuous spring end face grinding machine and rhombic spring production process applying same

A mill and sliding connection technology, applied in the field of spring processing, can solve problems such as low production efficiency, waste of production time, discontinuity, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

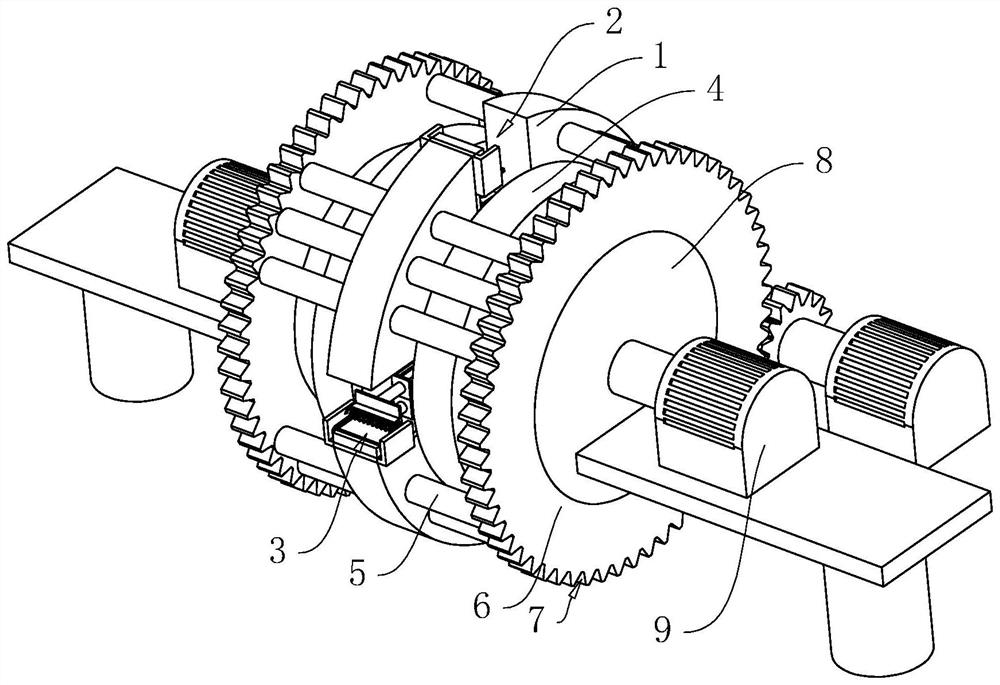

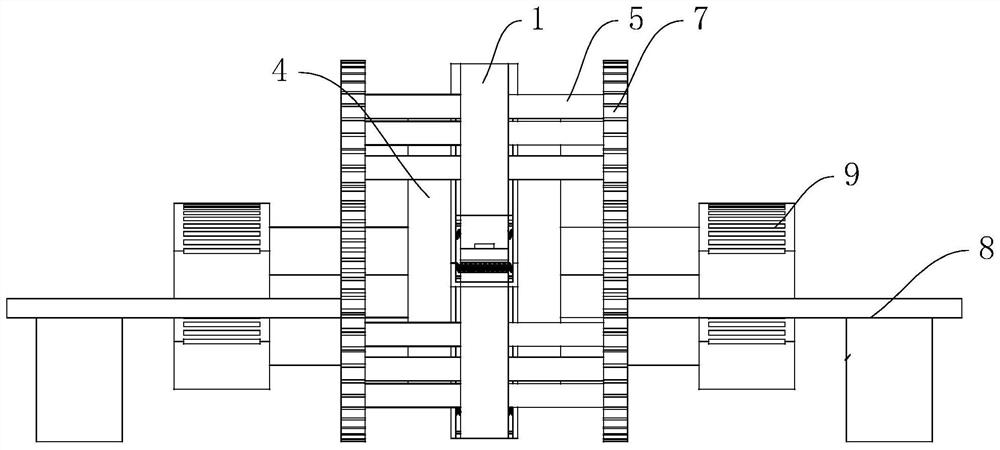

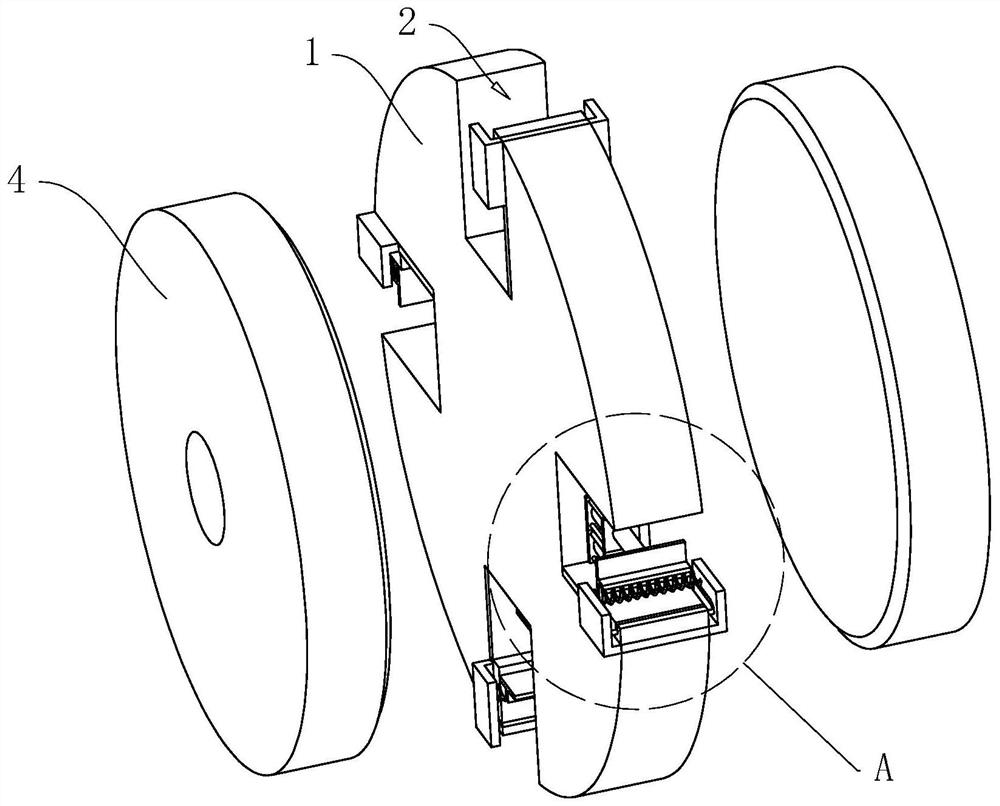

[0041] The following is attached Figure 1-5 The application is described in further detail.

[0042] The embodiment of the present application discloses a continuous spring end face grinding machine. refer to figure 1 with figure 2 , the continuous spring end face grinding machine includes a runner 1 with the axis horizontally arranged, and four installation through grooves 2 with rectangular openings are provided equidistantly along the circumference of the runner 1, and the installation through grooves 2 are opened along the axial direction of the runner 1 , and set on the outer opening of the runner 1, a limit mechanism 3 for the limit spring is installed in each installation through groove 2, the spring is limited on the limit mechanism 3 in the same direction as the drum spool, and the length of the spring is longer than that of the runner 1, and the two ends of the spring all exceed the same length of the two end surfaces of the runner 1, and both axial sides of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com