Water-based asphalt coating and preparation method thereof

A technology of asphalt coating and modified asphalt, applied in asphalt coatings, chloroprene homopolymer coatings, coatings, etc., can solve problems such as insufficient anti-slip ability, and achieve improved anti-slip ability and high mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

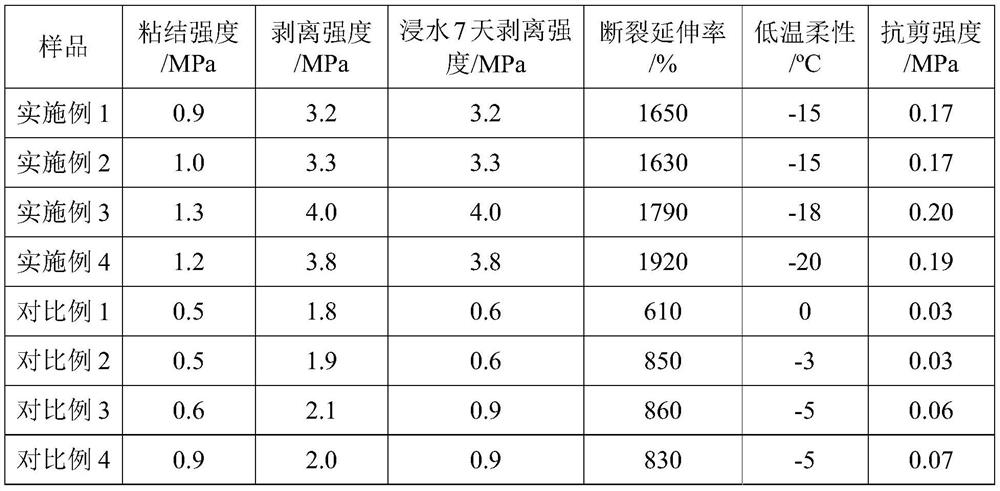

Examples

Embodiment 1

[0060] This embodiment provides a cross-linked water-based asphalt coating and a preparation method thereof.

[0061] Preparation of emulsified modified asphalt: (1) Take 260g Zhonghai 90 # Heat the asphalt to 145°C and stir evenly; (2) Add 10g of succinic anhydride and 30g of hydrogenated C5 petroleum resin to the asphalt simultaneously at a stirring speed of 300rpm, and stir for 1.5h after the addition to obtain modified asphalt; (3) Add 191g Add 0.12g NaOH to the water, after the dissolution is complete, add 9g lignosulfonate emulsifier, heat to 50°C, stir evenly to obtain soap liquid, pH is 12; (4) Pour 50°C soap liquid into the colloid mill, Turn on the colloid mill, slowly pour in the modified asphalt at 145°C, keep the colloid mill running for 30 seconds after pouring, and then close the colloid mill to obtain emulsified modified asphalt.

[0062] Preparation of aminosilane solution: (1) Add 0.03g of water dropwise to 1g of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilan...

Embodiment 2

[0065] This embodiment provides a cross-linked water-based asphalt coating and a preparation method thereof.

[0066] Preparation of emulsified modified asphalt: (1) 254g Zhonghai 70 # Heat the asphalt to 140°C and stir evenly; (2) Add 6g of maleic anhydride, 20g of C9 petroleum resin and 20g of rosin resin to the asphalt simultaneously at a stirring speed of 200rpm, and stir for 2 hours to obtain modified asphalt; (3) Add 0.16g NaOH to 189g water, after dissolving completely, add 11g fatty acid salt emulsifier, heat to 45°C, stir evenly to obtain soap liquid, pH is 12; (4) Pour the soap liquid at 45°C into the colloid mill , open the colloid mill, slowly pour in the modified asphalt at 140°C, keep the colloid mill running for 30 seconds after pouring, and then close the colloid mill to obtain emulsified modified asphalt.

[0067] Preparation of aminosilane solution: (1) Add 0.08g of water dropwise to 2g of bis(γ-trimethoxysilylpropyl)amine, and ultrasonically disperse for 20...

Embodiment 3

[0070] This embodiment provides a cross-linked water-based asphalt coating and a preparation method thereof.

[0071] Preparation of emulsified modified asphalt: (1) 235g Shell 90 # Heat the asphalt to 150°C and stir evenly; (2) Add 15g of glutaric anhydride and 50g of hydrogenated terpene resin to the asphalt simultaneously at a stirring speed of 400rpm, and stir for 3 hours after the addition to obtain modified asphalt; (3) Add 187g of water to the asphalt Add 0.2g NaOH, after the dissolution is complete, add 13g fatty acid salt emulsifier, heat to 50°C, stir evenly to obtain soap liquid, pH is 12; (4) Pour 50°C soap liquid into the colloid mill, open the colloid mill , slowly pour the modified asphalt at 150°C, keep the colloid mill running for 30s after pouring, and then close the colloid mill to obtain emulsified modified asphalt.

[0072] Preparation of aminosilane solution: (1) Drop 0.02g of water into 1g of N-β-(aminoethyl)-γ-aminopropyltriethoxysilane, ultrasonically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com