Energy recovery turbine blade material for low-temperature and high-acidity working conditions and preparation method of energy recovery turbine blade material

An energy recovery, turbine blade technology, applied in metal processing equipment, blade supporting elements, mechanical equipment, etc., can solve the problems of poor corrosion resistance and high cost of low temperature and high acid substances, optimize the manufacturing process, solve the corrosion resistance problem The effect of poor performance, good welding performance and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

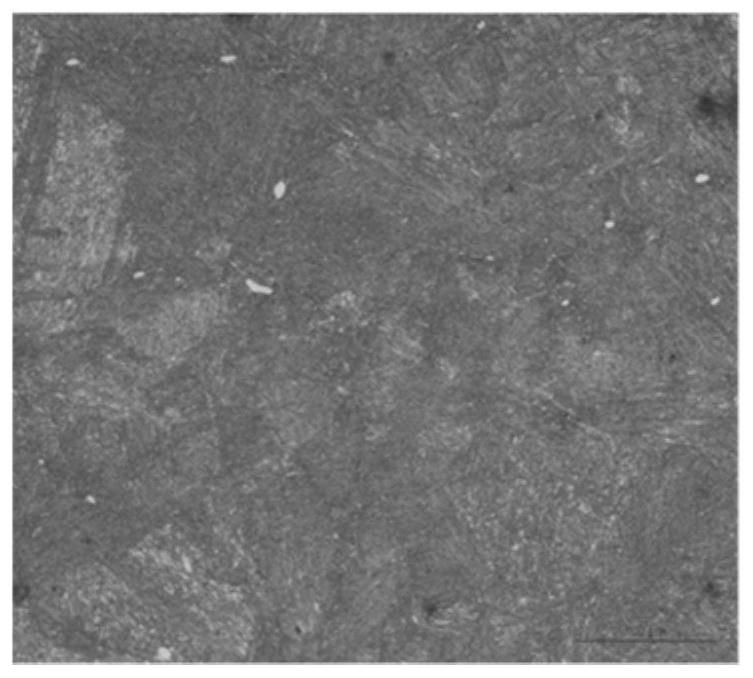

Examples

Embodiment 1

[0057] 1. According to the following composition, the ingredients are calculated in weight percentage:

[0058] C: 0.03%, Si: 0.7%, Mn: 1%, P: 0.01%, S: 0.001%, Cr: 11.5%, Ni: 4%, Mo: 1.2%, Cu: 2%, Nb: 0.3%, V: 0.045%, Al: 0.05%, Co: 0.02%, Nb+Ti+V: 0.35%, N: 0.02%, and the rest is Fe.

[0059] The mixed raw materials are smelted and cast in an electric furnace to obtain a primary steel ingot, and the primary steel ingot is subjected to secondary smelting and pouring in a vacuum state to obtain a secondary steel ingot as a billet. The smelting, casting and pouring processes for obtaining primary steel ingots and secondary steel ingots can be adjusted according to actual conditions.

[0060] 2. Forging and heat treatment after forging

[0061] The forging can be obtained by forging the secondary steel ingot as a blank in the austenite single-phase region, and air cooling to room temperature after forging. Among them, the initial forging temperature of the austenite single-ph...

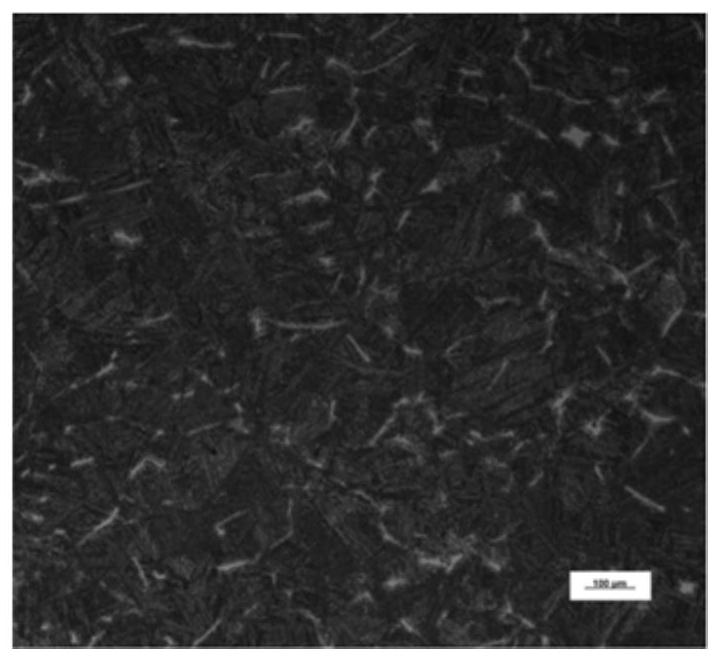

Embodiment 2

[0066] 1. According to the following composition, the ingredients are calculated in weight percentage:

[0067] C: 0.055%, Si: 0.3%, Mn: 0.55%, P: 0.02%, S: 0.003%, Cr: 14%, Ni: 4%, Mo: 1.5%, Cu: 1.5%, Nb: 0.35%, V: 0.05%, Al: 0.1%, Co: 0.1%, Nb+Ti+V: 0.45%, N: 0.06%, and the rest is Fe.

[0068] 2. Forging and heat treatment after forging

[0069] The forging can be obtained by forging the secondary steel ingot as a blank in the austenite single-phase region, and air cooling to room temperature after forging. Among them, the initial forging temperature in the austenite single-phase region is 1180°C, the final forging temperature is 900°C, at least three times of upsetting and three times of elongation are carried out, and the secondary deformation of the final fire is 52%, and the forging ratio is 7. Recrystallization cooling at 660°C was carried out.

[0070] 3. Performance heat treatment

[0071] The forgings are subjected to solution heat treatment, adjustment heat tre...

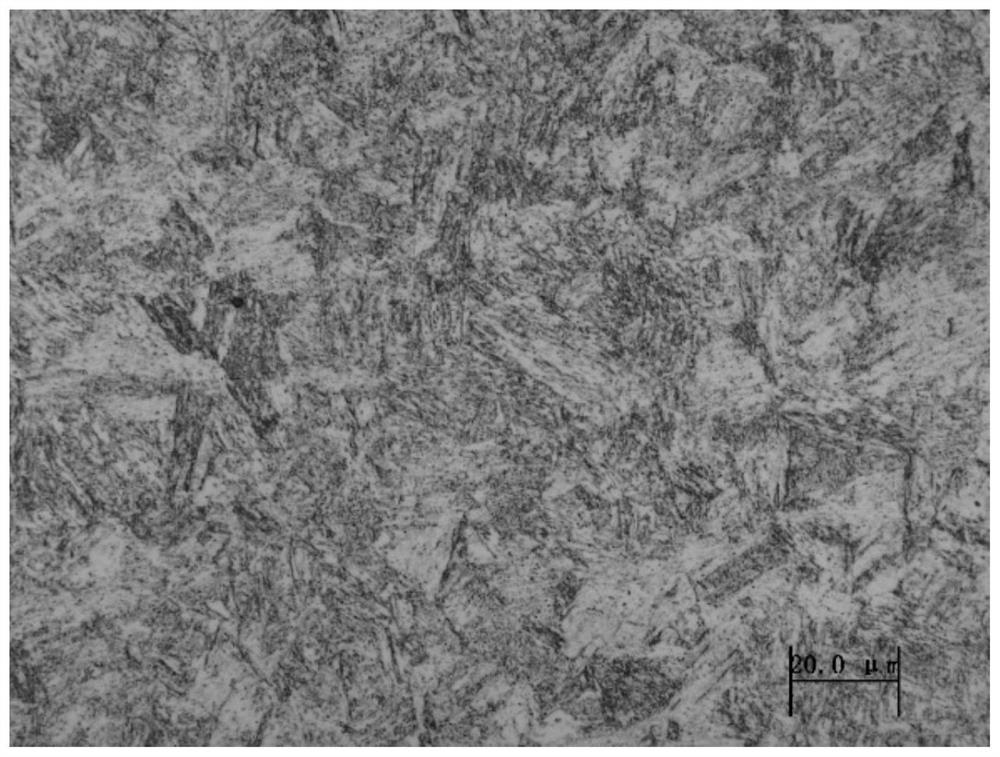

Embodiment 3

[0074] 1. According to the following composition, the ingredients are calculated in weight percentage:

[0075] C: 0.045%, Si: 0.2%, Mn: 0.6%, P: 0.02%, S: 0.005%, Cr: 12.5%, Ni: 3.5%, Mo: 1.6%, Cu: 2.2%, Nb: 0.15%, V: 0.04%, Al: 0.08%, Co: 0.03%, Nb+Ti+V: 0.3%, N: 0.05%, and the rest is Fe.

[0076] 2. Forging and heat treatment after forging

[0077] The forging can be obtained by forging the secondary steel ingot as a blank in the austenite single-phase region, and air cooling to room temperature after forging. Among them, the initial forging temperature of the austenite single-phase region is 1150°C, the final forging temperature is 880°C, at least three times of upsetting and three times of elongation are carried out, and the secondary deformation of the final fire is 48%, and the forging ratio is 6. Recrystallization cooling at 650°C was performed.

[0078] 3. Performance heat treatment

[0079] The forgings are subjected to solution heat treatment, adjustment heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com