A combined cooling, heating and power supply system based on PVT components and its operation method

A combined cooling, heating and power supply and cooling system technology, applied in the field of solar energy utilization, can solve problems such as the collector temperature exceeding the safe use range, the system cannot operate in rainy days, and hot water cannot be generated in time, so as to achieve a significant increase in power generation efficiency, Reduce the unevenness of heat transfer temperature and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

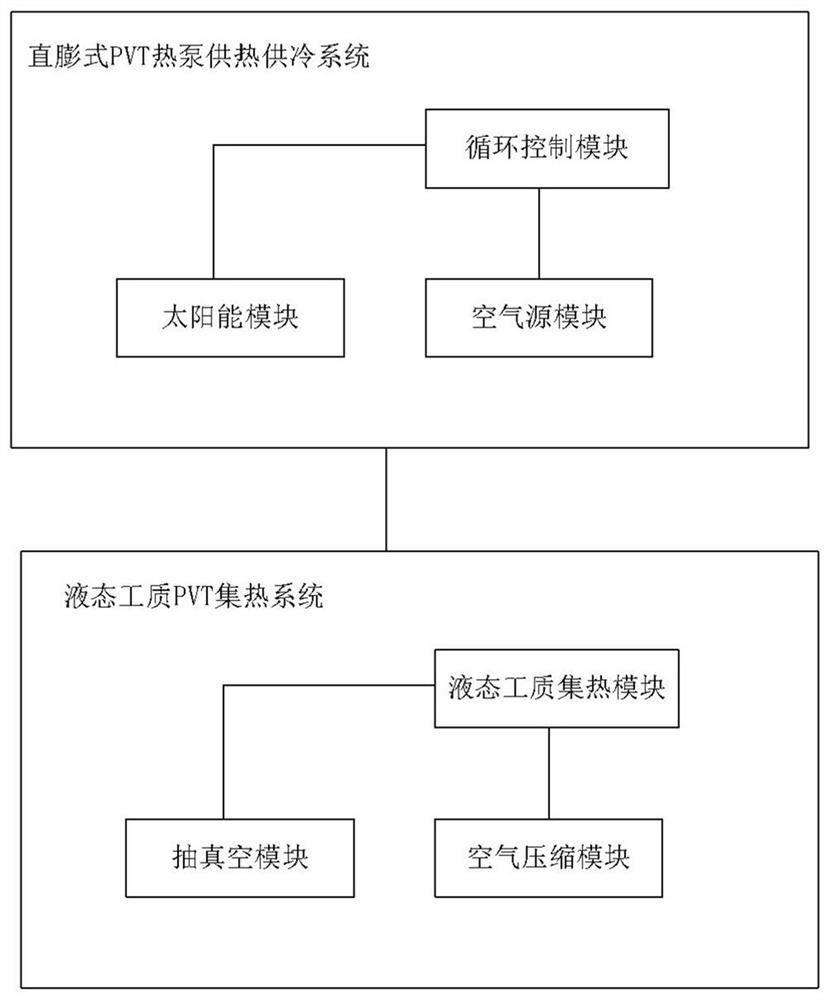

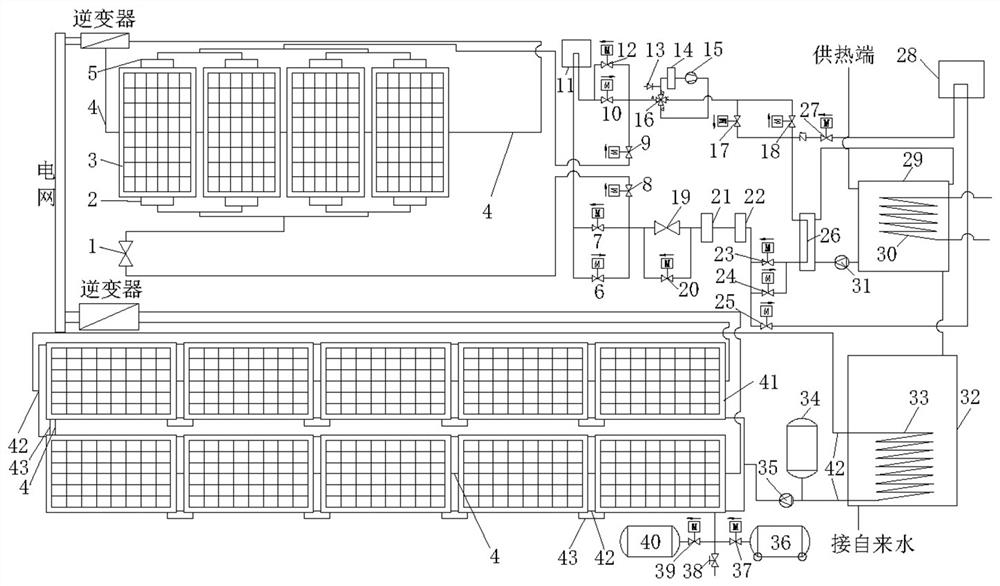

[0070] like figure 1 and figure 2 As shown, the combined cooling, heating and power system based on PVT components includes: liquid working fluid PVT heat collection system and direct expansion PVT heat pump heating and cooling system, liquid working fluid PVT heat collecting system and direct expansion PVT heat pump heating interconnection between cooling systems;

[0071] The liquid working fluid PVT heat collecting system includes an air compression module, a vacuum pumping module and a liquid working fluid heat collecting module; the air compression module and the vacuum pumping module are all connected with the liquid working fluid heat collecting module;

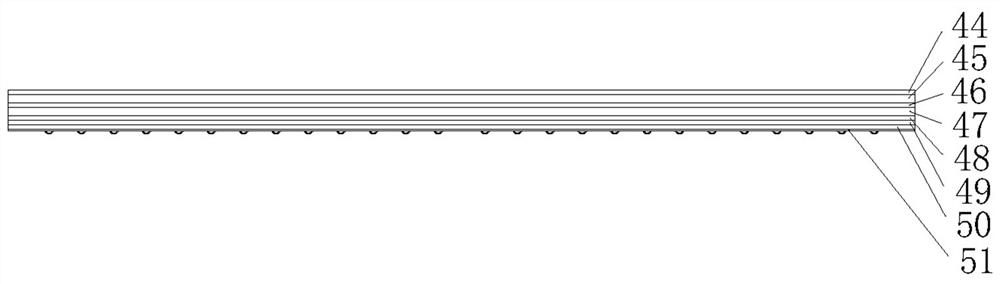

[0072] The air compression module includes an air compression unit 36 and a fourteenth electric valve 37; the vacuuming module includes a fifteenth electric valve 39 and a vacuuming unit 40; the liquid working medium heat collecting module includes a hot water tank 32, a first heat exchanger 33. Expansion tank 34,...

Embodiment 2

[0081] A method for operating a combined cooling, heating and power supply system based on PVT components, which is operated by a combined cooling, heating and power supply system based on PVT components. The PVT heat pump heating and cooling system has solar water heating mode, solar hot water defrosting mode, air source hot water heating mode, air source heating water defrosting mode and cooling mode.

[0082] The solar collector operation mode specifically includes the following steps:

[0083] Step 1. Open the fourteenth electric valve 37, and the air compression unit 36 inflates the inflatable insulation layer 72;

[0084] Step 2. After the gas-filled insulating layer 72 fills the space between the liquid working fluid heat exchanger 71 and the insulating layer 73, the fourteenth electric valve 37 is closed;

[0085] After step 2 is performed, the liquid working fluid PVT heat collector 41 has good heat preservation performance.

[0086] Step 3, turn on the second cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com