Injection molding heat exchanger device

A technology of injection molding and injection molding technology, which is applied in the direction of heat exchanger sealing device, indirect heat exchanger, heat exchanger type, etc., can solve the problems of high skill level requirements, limited production capacity improvement, and difficult processing, etc. Achieve the effect of simplifying the processing procedure, improving production efficiency and reducing the difficulty of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

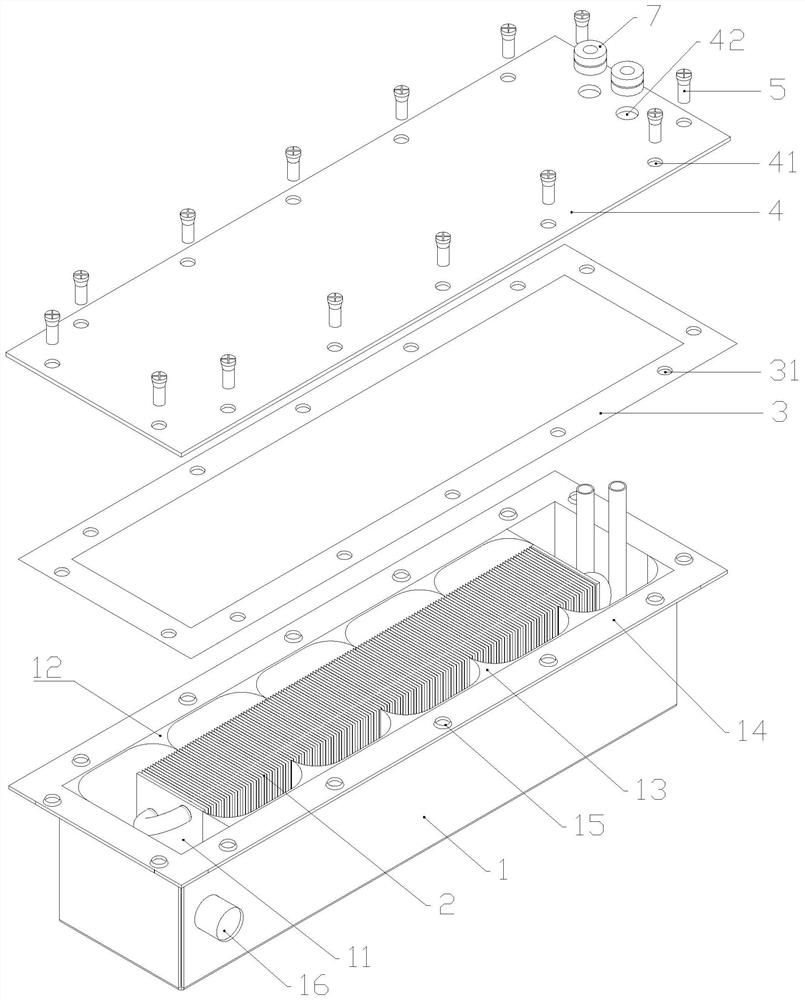

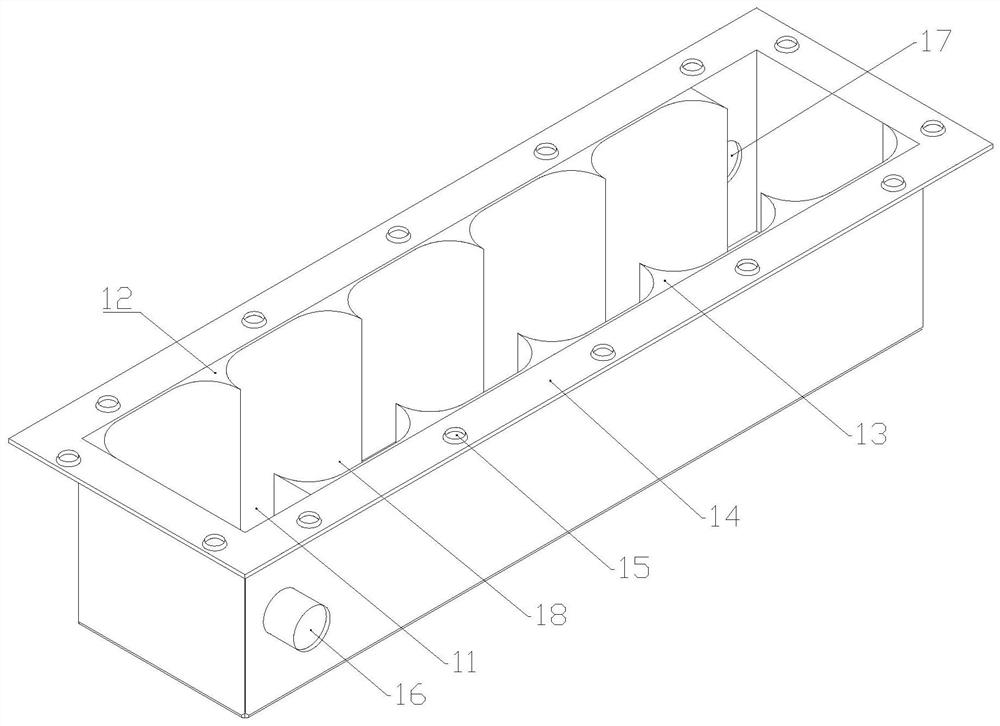

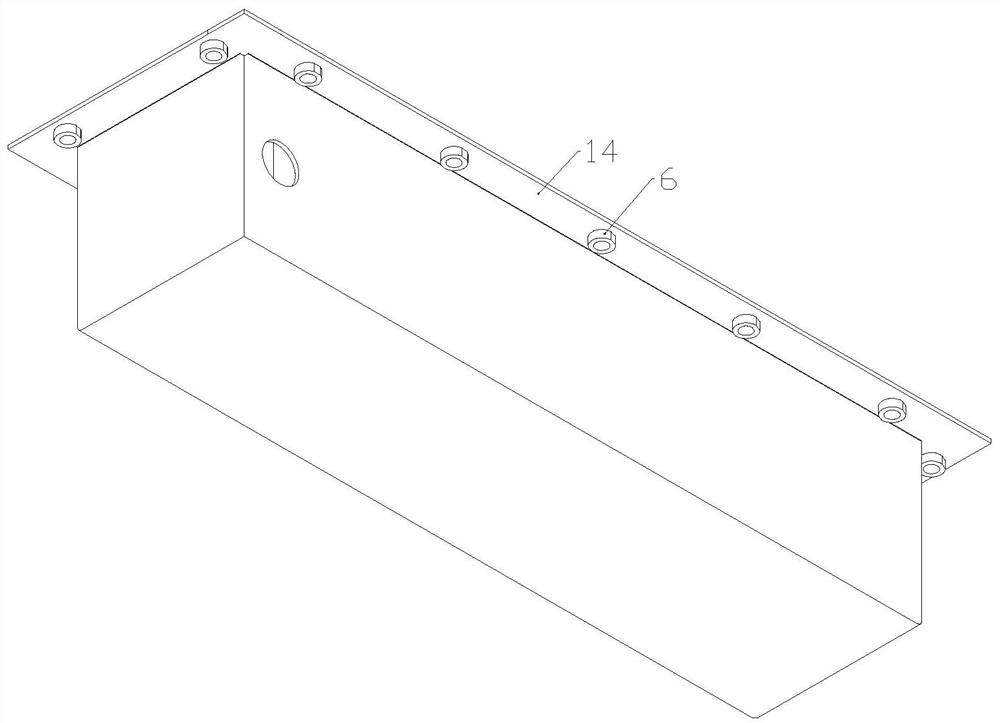

[0026] For describing in detail the technical features of the present invention and the achieved objects and effects, further description is done below in conjunction with the accompanying drawings:

[0027] like Figure 1-6 As shown, an injection molding heat exchanger device includes a plastic shell 1, the plastic shell 1 is integrally formed by an injection molding process, and the plastic shell 1 includes a groove 11 opened inside and the front and rear inner walls of the groove 11 The positions of the first baffle 12 and the second baffle 13 are arranged symmetrically in the center, and the first baffle 12 and the second baffle 13 A cooling liquid channel 18 is formed between 13, the plastic shell 1 is provided with a cooling liquid inlet 16 on the left side of the front wall, and a cooling liquid outlet 17 on the right side of the rear wall; a heat exchange core 2 is installed in the groove 11, and the heat exchange The core 2 includes end plates 21 at the left and righ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com