Broadband wave-absorbing composite material and preparation method thereof

A composite material and broadband technology, which is applied in the field of broadband absorbing composite materials and its preparation, can solve the problems such as the inability to finely adjust the gradient effect of layer and layer impedance and the reduction of structural strength. The effect of a good impedance gradient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

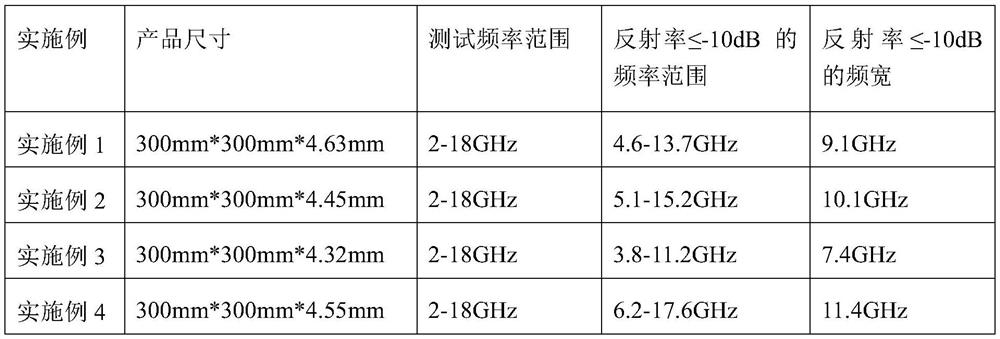

Examples

preparation example Construction

[0017] According to a typical embodiment of the present invention, a preparation method of a broadband wave-absorbing composite material is provided. The preparation method comprises the following steps: 1) Stir and disperse one or both of carbon nanotubes and MXenes in an aqueous graphene oxide dispersion to obtain a wave absorbing agent slurry; 2) in the wave absorbing agent slurry Add polymer particles of different sizes, and then obtain polymer particles with surface-coated absorbing components through mechanical stirring, filtration, and vacuum drying steps, that is, absorbing particles; 3) According to the requirements of the multi-layer design scheme, different The microwave-absorbing particles with different agent content and / or different sizes are sprinkled in the heat-pressing mold; and 4) closing the heat-pressing mold, and obtaining a broadband wave-absorbing composite material by heat-pressing.

[0018] Applying the technical solution of the present invention, in ...

Embodiment 1

[0026] 1) Preparation of wave absorbing agent slurry: Add carboxylated multi-walled carbon nanotubes with diameters of 8 to 15 nm and lengths of 3 to 5 μm in different numbers of graphene oxide dispersions at 5 mg / ml, mechanically stir and disperse for 30 minutes, and absorb Wave agent slurry. The ratios of graphene oxide and carbon nanotubes in the wave absorbing agent slurry are 1:0.2, 1:0.5, 1:0.7, 1:1, 1:1.5, 1:2, 1:3, respectively;

[0027] 2) Add polystyrene microspheres with a size of 30 μm to the seven ratios of wave-absorbing agent slurry obtained in step 1), and disperse with high-speed mechanical stirring for 120 minutes, so that the wave-absorbing agent is coated on the surface of the polystyrene microspheres.

[0028] 3) Filter out the coated polystyrene microspheres in step 2), and dry them in vacuum at 90 degrees Celsius for 12 hours in a vacuum drying oven to obtain polystyrene microspheres coated with wave-absorbing components on the surface, that is, wave-abs...

Embodiment 2

[0032] 1) Preparation of wave absorbing agent slurry: Add carboxylated multi-walled carbon nanotubes with a diameter of 8-15 nm and a length of 0.5 to 2 μm in a 5 mg / ml graphene oxide dispersion, and mechanically stir and disperse for 30 minutes to obtain a wave absorbing agent slurry material. The ratio of graphene oxide to carbon nanotubes in the dispersion is 1:1.5;

[0033] 2) The seven parts of wave absorbing agent slurry obtained in step 1) were respectively mixed with polystyrene microspheres with sizes of 113 μm, 87 μm, 65 μm, 46 μm, 25 μm, 17 μm, and 8 μm, and dispersed by high-speed mechanical stirring for 120 minutes, so that the wave absorbing agent package onto the surface of polystyrene microspheres.

[0034] 3) Filter out the coated polystyrene microspheres in step 2), and dry them in vacuum at 90 degrees Celsius for 12 hours in a vacuum drying oven to obtain polystyrene microspheres coated with wave-absorbing components on the surface, that is, wave-absorbing co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com