Process for purifying methyl methacrylate to remove low boiling components

A technology of alkyl methacrylate and methacrolein, which is applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of organic compounds, etc., and can solve problems such as expensive variants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

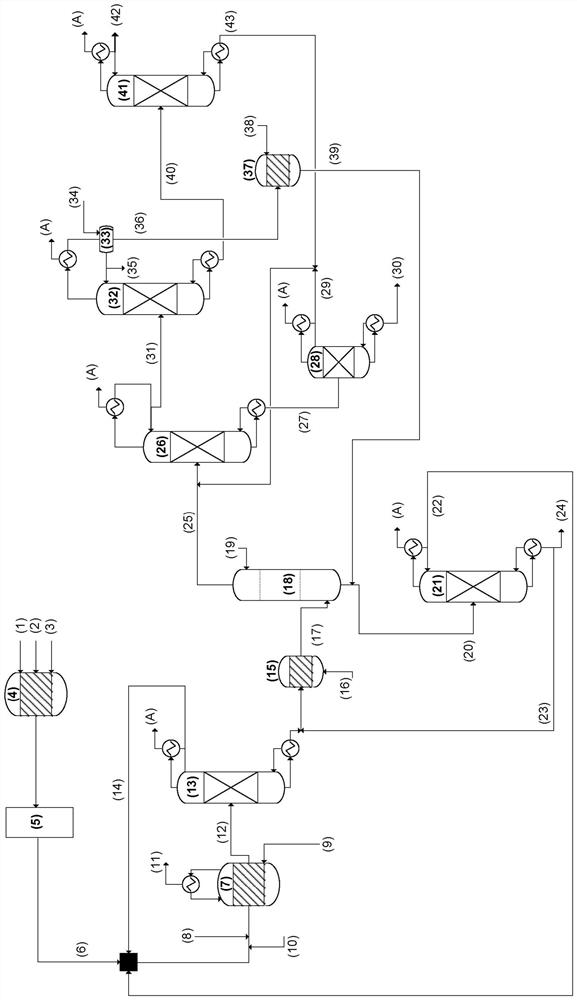

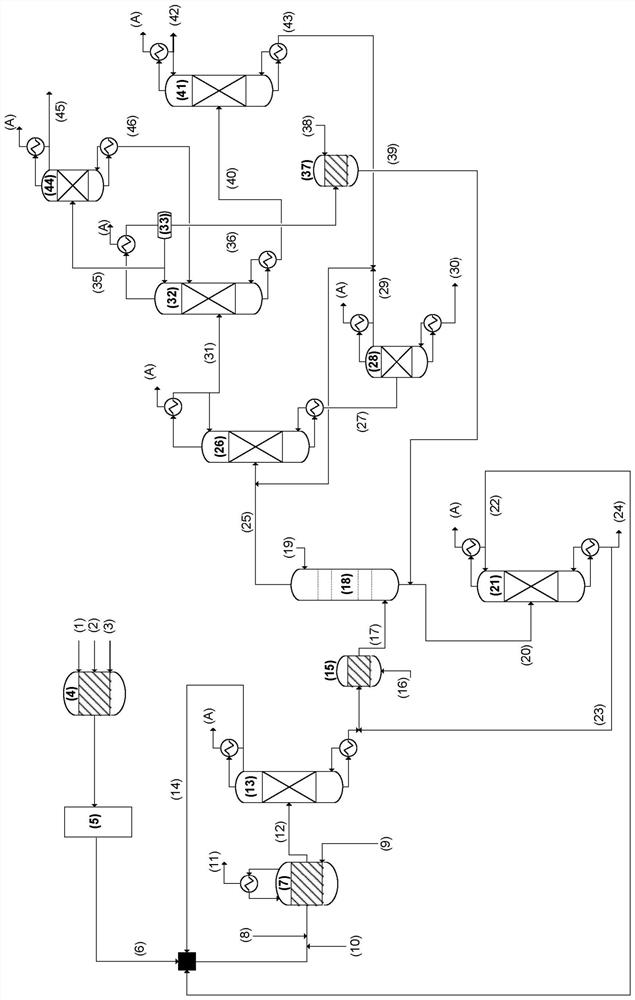

[0045] stay Figure 1 In the continuous operation equipment shown in, the distillate stream (31) of the high boiling tower (Distillation Tower IV) (26) is generated and purified by distillation in the subsequent low boiling tower (distillation tower I) (32) to remove the low boiling. With this operation, MMA bottom stream containing process stabilizer can be generated, which has PRAME content of < 10 ppm and ibsme content of < 350 ppm.

[0046] The low boiling tower is operated at an absolute operating pressure of 250 mbar. The tower is equipped with structured packing M750 from Sulzer Y (diameter 100mm, filling height 12000mm, feeding at 6000mm). Add the process stabilizer to the condenser. The process stabilizer is dissolved in MMA and added at a rate of 330g / h. The temperature is controlled at an operating temperature of 20 ° C and a phase separator with water feeding (34) produces an aqueous phase (36) and an organic phase. The organic phase is recirculated into the tower as ...

Embodiment 2

[0049] Using the tower (250 mbar absolute operating pressure) and phase separator (operating temperature 20 ℃) of example 1, the distillate stream (31) (11000g / h) of the high boiling tower is distilled, including 96.7 wt% MMA and 1.8 wt% H 2 O. 0.1 wt% mal, 0.1 wt% PRAME, 0.2 wt% ibsme and 1.1 wt% residue). Here, the ratio of reflux to feed is set to 2.2 and the discharge stream is fixed at 25 g / h. The water addition rate in the phase separator is 1530 g / h. This results in a top temperature of 54 ° C and a bottom temperature of 62 ° C. The aqueous stream (36) of the phase separator is 1858 g / h and contains 1.6% by weight of MMA and 91.8% by weight of H 2 O. 0.4 wt% mal, 0.4 wt% PRAME, 0.5 wt% ibsme and 4.9 wt% residue. The bottom output (40) is 11035g / h, which consists of 99.91 wt% MMA, 35ppm PRAME, 315ppm ibsme and 0.06 wt% process stabilizer. This mode of operation described achieves an MMA retention rate of 99.71%.

Embodiment 3

[0051] In the tower (250 mbar absolute operating pressure) and phase separator (operating temperature 20 ℃) of embodiment 1, the distillate stream (31) (11000g / h) of the distillation high boiling tower contains 96.7 wt% MMA and 1.8 wt% H 2 O. 0.1 wt% mal, 0.1 wt% PRAME, 0.2 wt% ibsme and 1.1 wt% residue). Here, the ratio of reflux to feed is set to 2.0 and the discharge flow is fixed at 25 g / h. No water is added to the phase separator. This results in a top temperature of 50 ° C and a bottom temperature of 62 ° C. The aqueous stream (36) of the phase separator is 335g / h and contains 5.5% by weight of MMA and 60.0% by weight of H 2 O. 2.0 wt% mal, 1.5 wt% PRAME, 2.0 wt% ibsme and 29.0 wt% residue. The bottom output (40) is 11000 g / h, which consists of 99.9 wt% MMA, 55 ppm PRAME, 320 ppm ibsme and 0.06 wt% process stabilizer. The MMA retention rate of 99.51% is achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com