Special ultralow-emission desulfurization solvent for SCOT tail gas of sulfur recovery device in oil refinery

A technology for sulfur recovery and oil refinery, which is applied in the direction of gas fuel, petroleum industry, separation methods, etc. It can solve the problems that the extended tail gas treatment process cannot be achieved, and achieve high removal rate and small bubble loss without affecting the service life of the equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

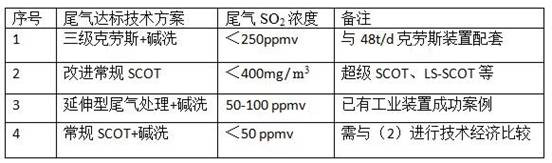

Problems solved by technology

Method used

Image

Examples

Embodiment 1

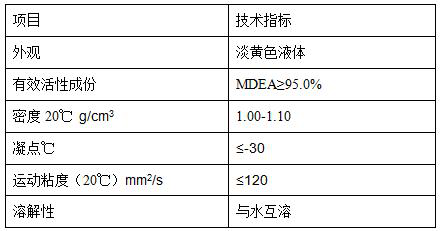

[0060] A special ultra-low emission desulfurization solvent for SCOT tail gas of refinery sulfur recovery unit, which comprises the following components in terms of mass percentage,

[0061] MDEA 95.6%;

[0062] Piperazine 2.4%;

[0063] Water 1.9%;

[0064] Special defoamer for desulfurization agent 0.1%.

[0065] Described MDEA is N-methyldiethanolamine, and its molecular formula is CH 3 N(CH 2 CH 2 Oh) 2 .

[0066] The molecular formula of the piperazine is C 4 h 10 N 2 .

[0067] The special defoamer for desulfurizer is modified simethicone.

[0068] Add MDEA, piperazine, water, and special defoamer for desulfurization agent into the reaction kettle and stir to obtain ultra-low emission desulfurization solvent for SCOT tail gas of refinery sulfur recovery unit.

Embodiment 2

[0070] A special ultra-low emission desulfurization solvent for SCOT tail gas of refinery sulfur recovery unit, which comprises the following components in terms of mass percentage,

[0071] MDEA 95.7%;

[0072] Piperazine 2.3%;

[0073] Water 1.8%;

[0074] Special defoamer for desulfurization agent 0.2%.

[0075] Described MDEA is N-methyldiethanolamine, and its molecular formula is CH 3 N(CH 2 CH 2 Oh) 2 .

[0076] The molecular formula of the piperazine is C 4 h 10 N 2 .

[0077] The special defoamer for desulfurizer is modified simethicone.

[0078] Add MDEA, piperazine, water, and special defoamer for desulfurization agent into the reaction kettle and stir to obtain ultra-low emission desulfurization solvent for SCOT tail gas of refinery sulfur recovery unit.

Embodiment 3

[0080] A special ultra-low emission desulfurization solvent for SCOT tail gas of refinery sulfur recovery unit, which comprises the following components in terms of mass percentage,

[0081] MDEA 95.9%;

[0082] Piperazine 2.1%;

[0083] Water 1.7%;

[0084] Special defoamer for desulfurization agent 0.3%.

[0085] Described MDEA is N-methyldiethanolamine, and its molecular formula is CH 3 N(CH 2 CH 2 Oh) 2 .

[0086] The molecular formula of the piperazine is C 4 h 10 N 2 .

[0087] The special defoamer for desulfurizer is modified simethicone.

[0088] Add MDEA, piperazine, water, and special defoamer for desulfurization agent into the reaction kettle and stir to obtain ultra-low emission desulfurization solvent for SCOT tail gas of refinery sulfur recovery unit.

[0089] The high-efficiency desulfurizer with MDEA as the main agent of the present invention fully demonstrates that its sulfur capacity is large and the advantages of good selectivity, and the existen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com