Pneumatic crane

A crane and rotating groove technology, which is applied in the direction of grinding machine parts, load hanging components, metal processing equipment, etc., can solve the problem of wire rope rust being difficult to deal with, and achieve the purpose of avoiding random splashing, reducing burden and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

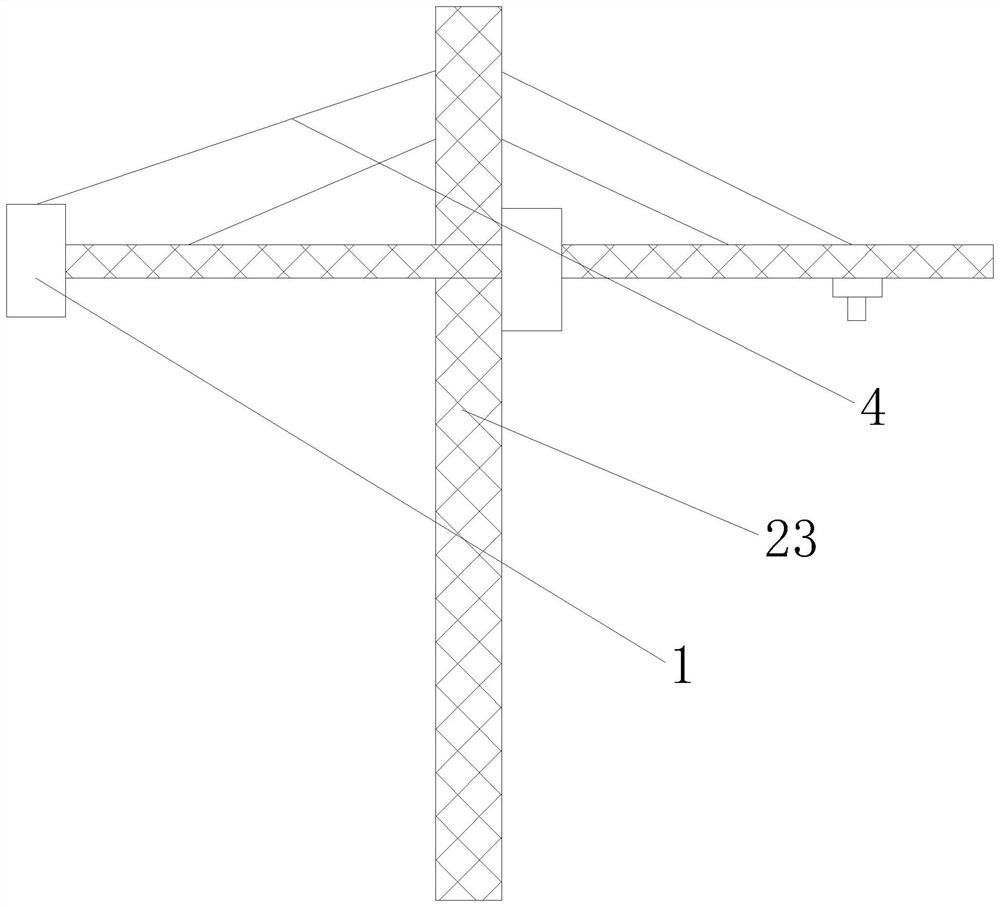

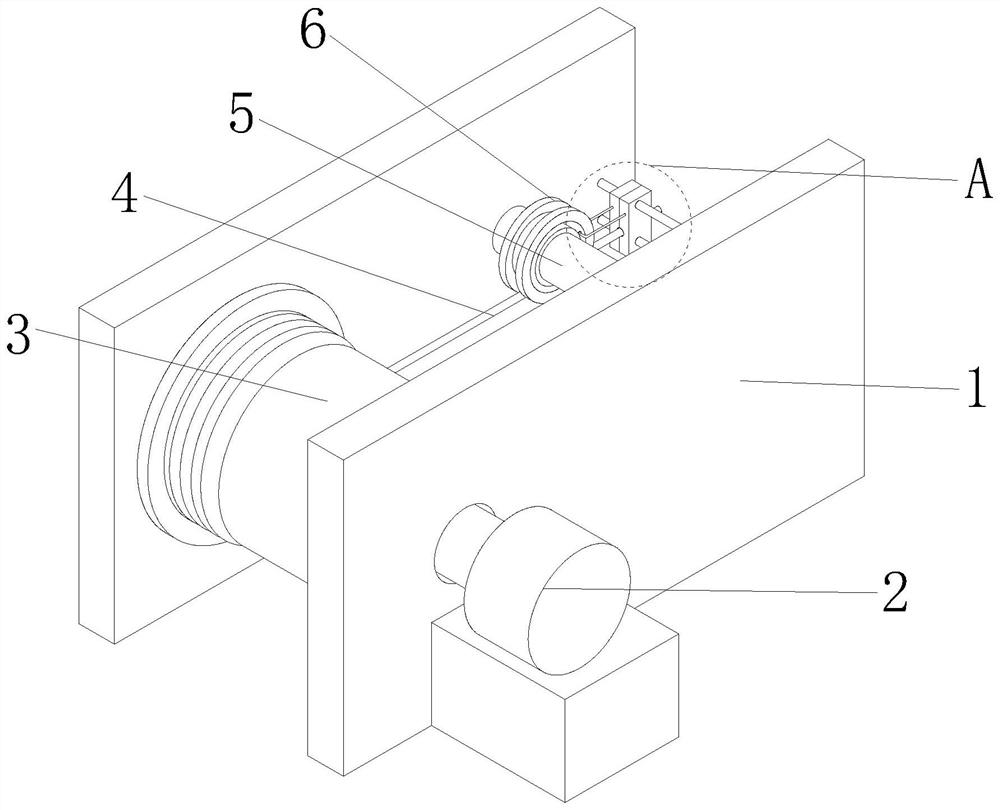

[0033] see Figure 1-2 , the present invention provides a technical solution: a pneumatic crane, including a pneumatic crane body 23, a fixed frame 1, a motor 2, a wire roller 3, a steel wire rope 4, a fixed rod 5, and a cable pulley 6, and the fixed frame 1 is fixedly connected to the crane On the body 23, the output end of the motor 2 runs through the right side of the fixed frame 1 and is fixedly connected with the wire roller 3. The left and right ends of the wire roller 3 are respectively connected to the left and right sides of the inner wall of the fixed frame 1. Be respectively fixedly connected on the left and right sides of the fixed frame 1 inner wall, the inner ring of the cable pulley 6 is connected with the surface of the fixed rod 5 in rotation, the rear end of the wire rope 4 is arranged on the surface of the wire roller 3, and the end of the wire rope 4 away from the wire roller 3 is connected to the wire roller 3. The surface of the wire arranging wheel 6 is ...

Embodiment 2

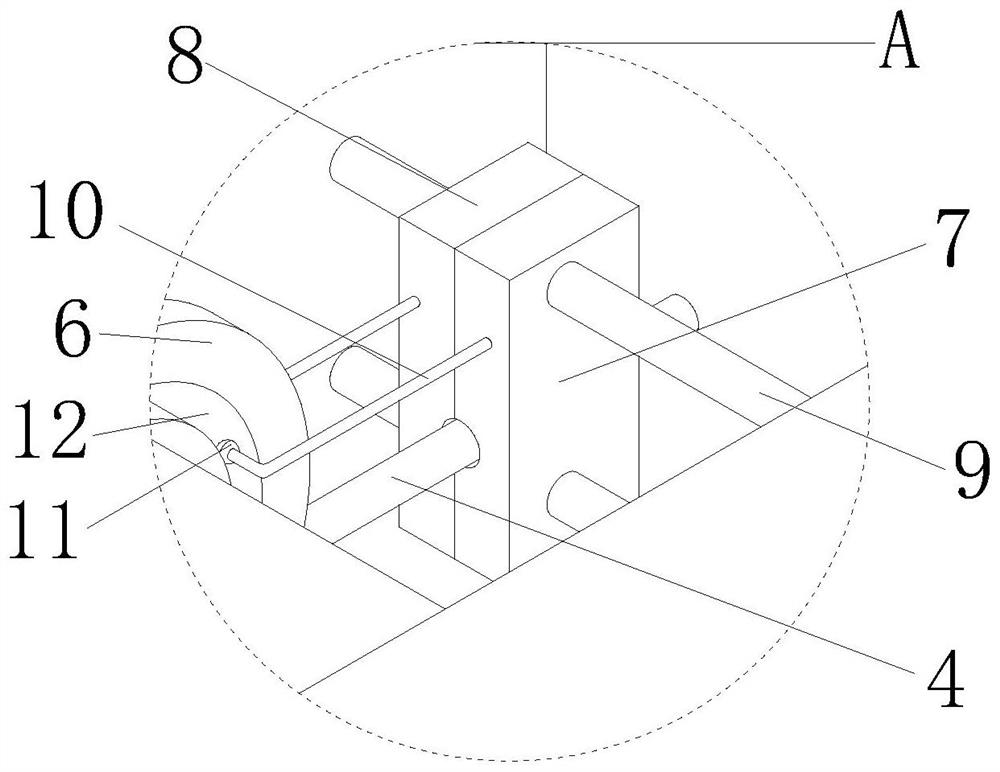

[0036] see image 3, on the basis of Embodiment 1, the left and right sides of the cable wheel 6 are provided with rotating grooves 12, and the inner walls of the two rotating grooves 12 are slidingly connected with two connecting rods 10 in the shape of an "L". The rear end of the rod 10 is inlaid with rotating balls 11, and the surfaces of the two rotating balls 11 are slidingly connected with the inner walls of the two rotating grooves 12 respectively. It is set so that the two connecting rods 10 cannot break away from the rotating groove 12, so that the two connecting rods 10 can move along with the movement of the cable arrangement wheel 6, thereby ensuring the smooth operation of the device, and the two connecting rods 10 are far away from the cable arrangement One end of wheel 6 is provided with cleaning mechanism, and cleaning mechanism comprises the first cleaning shell 8, the second cleaning shell 7, and the first cleaning shell 8 and the second cleaning shell 7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com