FRPP ultra-silence drain pipe

A drainage pipe, ultra-quiet technology, applied in the field of drainage pipes, can solve the problems of injury to workers or construction personnel, large energy consumption and dust pollution, poor noise reduction effect of drainage pipes, etc., to avoid permanent damage and reduce dust pollution , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

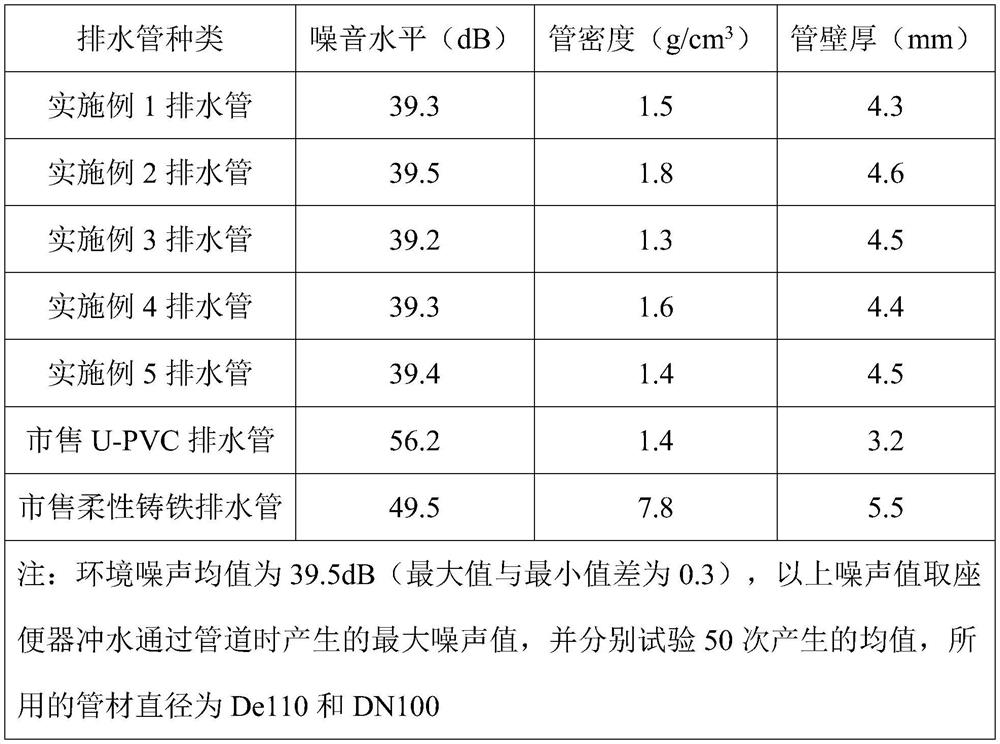

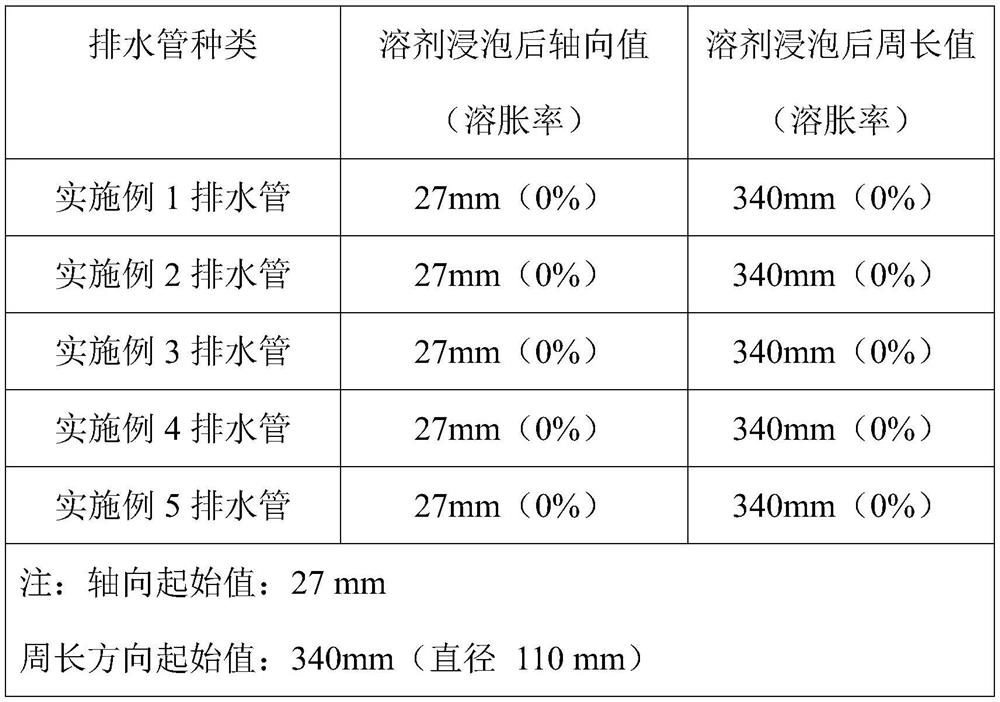

Examples

Embodiment 1

[0020] An FRPP ultra-quiet drainage pipe is composed of an inner layer, a core layer and an outer layer, wherein the core layer is located between the inner layer and the outer layer; The inner layer consists of the following raw materials in percentage by weight: 99.3% of polypropylene and 0.7% of masterbatch; The core layer consists of the following raw materials in percentage by weight: 48% of polypropylene, 31.5% of calcium carbonate, 18% of barium sulfate and 2.5% of glass fiber; The diameter of the glass fiber is 5μm, and the length of the glass fiber is 5 mm; The outer layer consists of the following raw materials in percentage by weight: 99.3% of polypropylene and 0.7% of masterbatch.

Embodiment 2

[0022] An FRPP ultra-quiet drainage pipe is composed of an inner layer, a core layer and an outer layer, wherein the core layer is located between the inner layer and the outer layer; The inner layer consists of the following raw materials in percentage by weight: 99.4% of polypropylene and 0.6% of masterbatch; The core layer consists of the following raw materials in percentage by weight: 49% of polypropylene, 30.2% of calcium carbonate, 19.5% of barium sulfate and 1.3% of glass fiber; The diameter of the glass fiber is 5μm, and the length of the glass fiber is 5 mm; The outer layer consists of the following raw materials in percentage by weight: 99.4% of polypropylene and 0.6% of masterbatch.

Embodiment 3

[0024] An FRPP ultra-quiet drainage pipe is composed of an inner layer, a core layer and an outer layer, wherein the core layer is located between the inner layer and the outer layer; The inner layer consists of the following raw materials in percentage by weight: 99.5% of polypropylene and 0.5% of masterbatch; The core layer consists of the following raw materials in percentage by weight: 50% of polypropylene, 30% of calcium carbonate, 18.5% of barium sulfate and 1.5% of glass fiber; The diameter of the glass fiber is 5μm, and the length of the glass fiber is 5 mm; The outer layer consists of the following raw materials in percentage by weight: 99.5% of polypropylene and 0.5% of masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com