Visual clogging simulation system of gravel pile drainage structure and simulation method thereof

A technology of drainage structure and simulation system, applied in suspension and porous material analysis, instrument, permeability/surface area analysis, etc. The design of the effect of pile drainage and anti-liquefaction, to achieve the effect of facilitating the adjustment of parameters and the measurement of subsequent test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

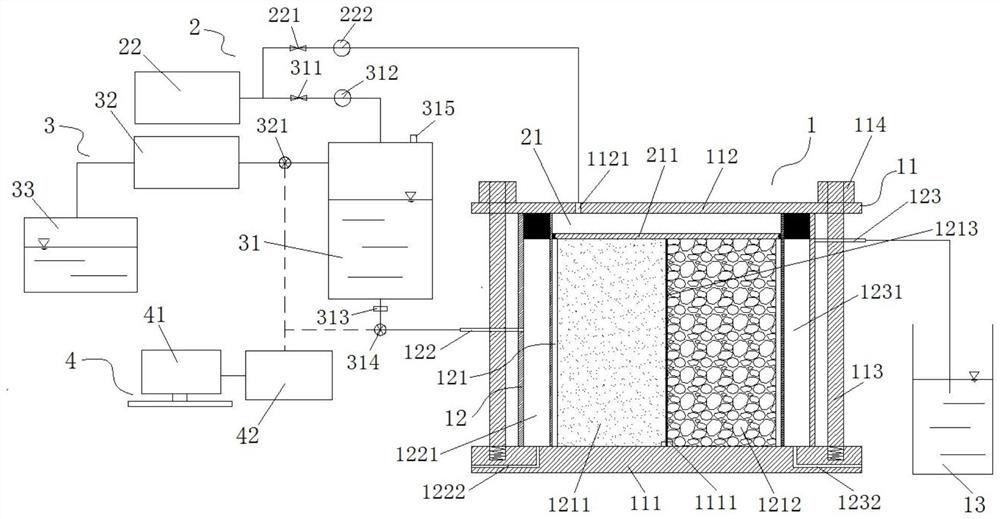

[0046] Such as Figure 1-4 As shown, this embodiment provides a visual silting simulation system for the drainage structure of gravel piles, which mainly includes a gradation simulation device 1 , a vertical stress loading device 2 , an osmotic pressure loading device 3 and a control system 4 .

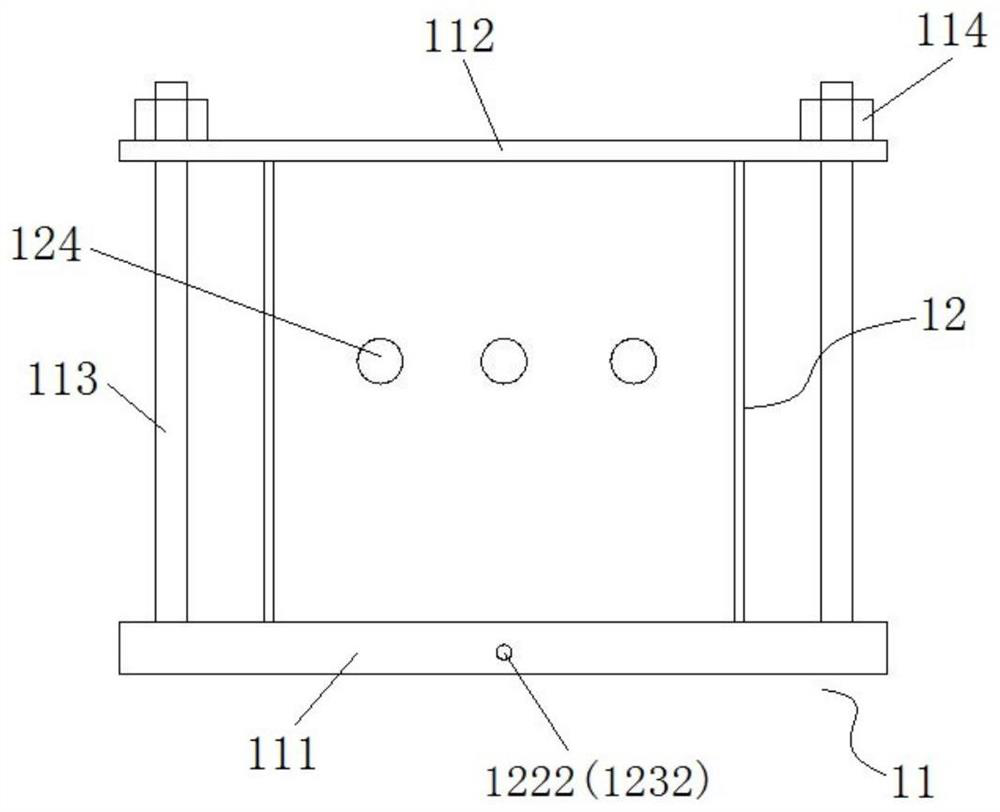

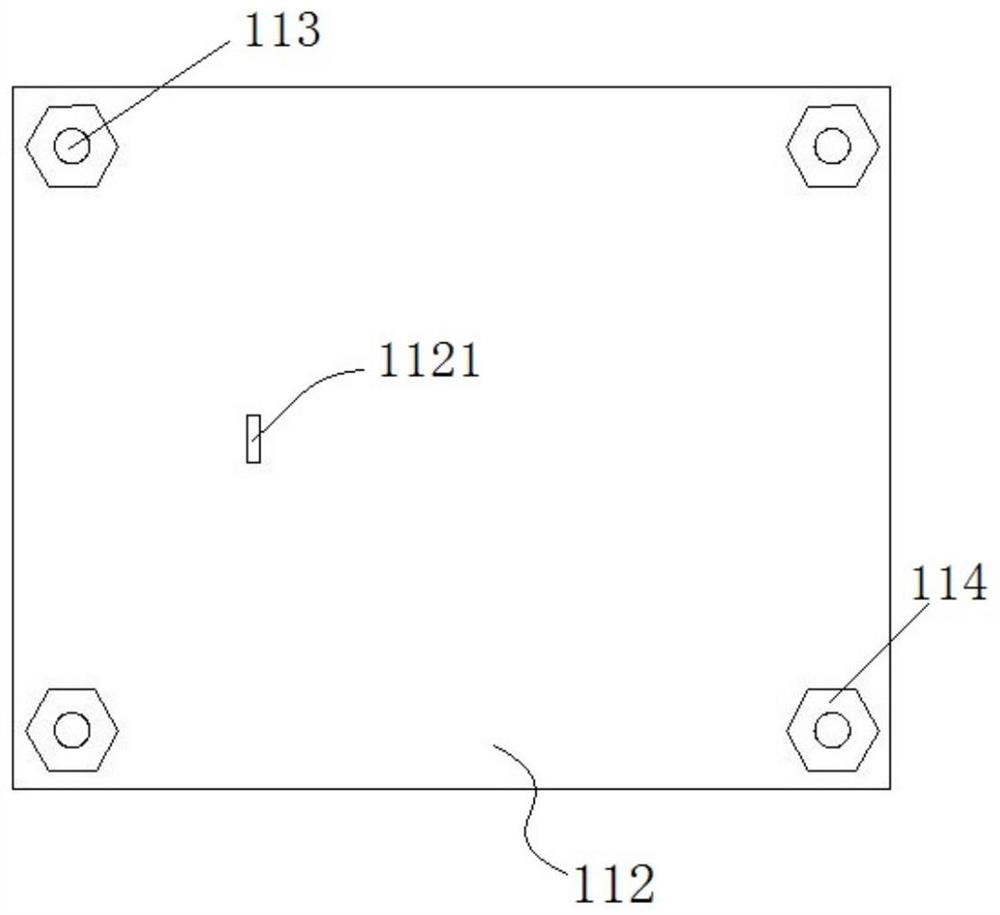

[0047] The gradation simulation device 1 mainly includes a device frame 11 and a model tank 12 arranged on the device frame 11 . Specifically, as one of the preferred solutions, the device frame 11 in this embodiment includes a base 111, a cover plate 112 and several connecting rods 113, the base 111 and the cover plate 112 are both rectangular The plate is set, the bottom of the model tank 12 is fixed on the base 111, and the cover plate 112 is detachably installed on the top of the model tank 12; one end of the connecting rod 113 is for mounting It is arranged on the base 111 and is located outside the mold groove 12 , and the other end of the connecting rod 113 is set on the cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com