Method for testing bonding strength of emulsified asphalt

A technology of emulsified asphalt and bond strength, which is applied in the field of bond strength test of emulsified asphalt, can solve problems such as low efficiency, long test piece production cycle, road surface damage, etc., and achieve the effect of improving construction efficiency and construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

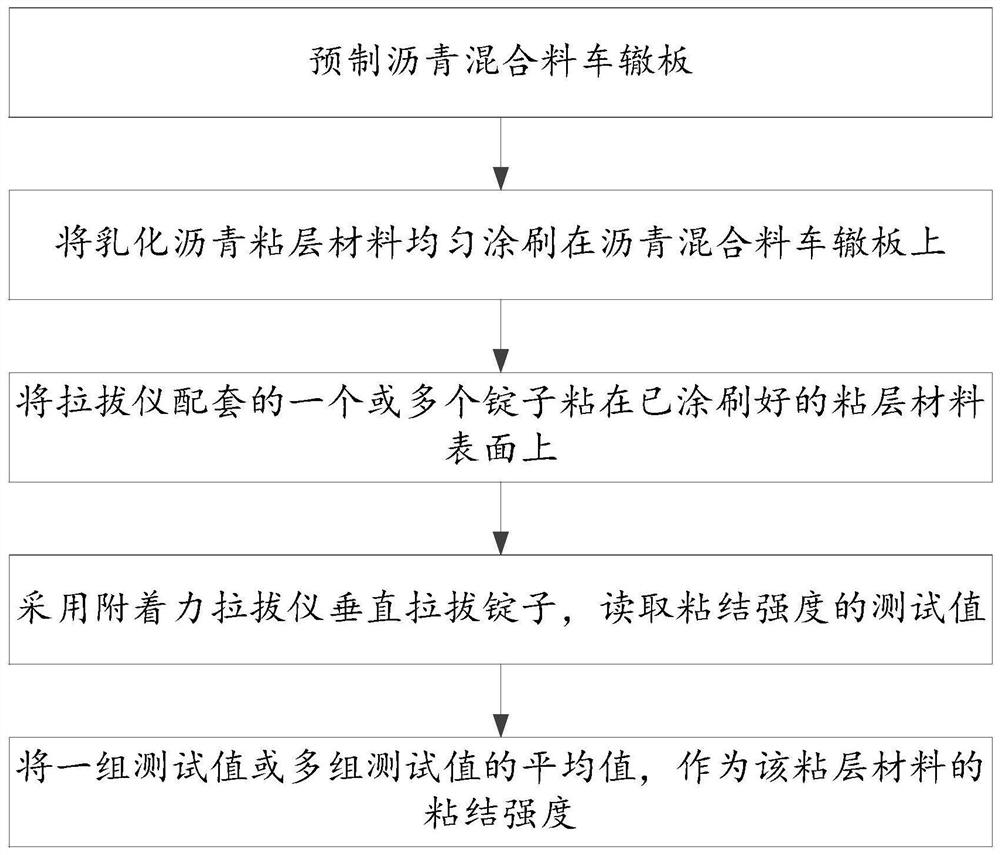

Method used

Image

Examples

Embodiment 1

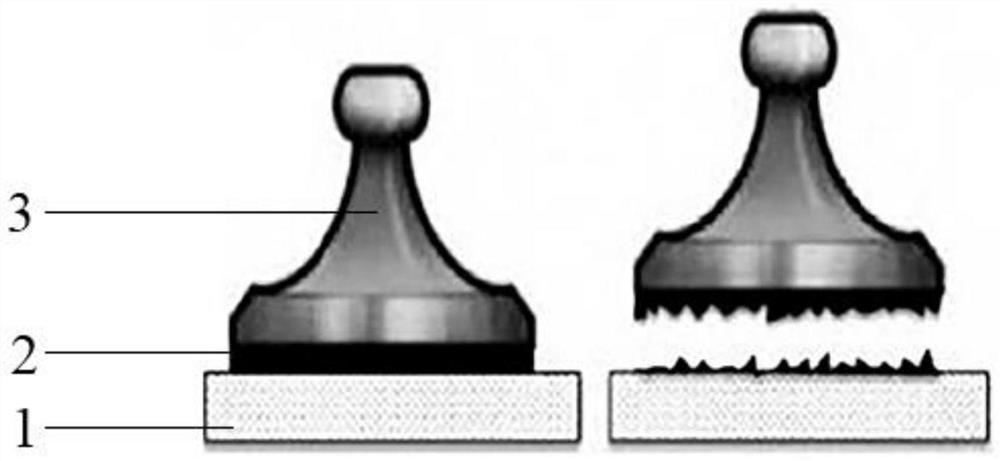

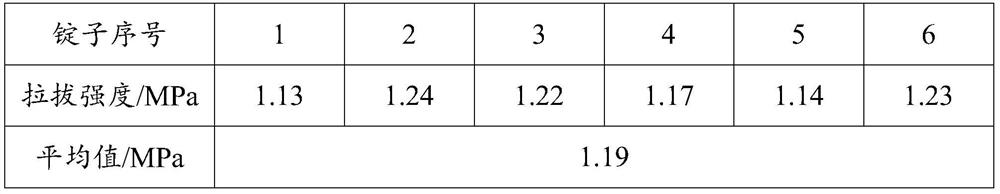

[0038] Prefabricate 30cm×30cm×5cm AC-10 asphalt mixture rutting slabs to prepare SBR modified emulsified asphalt with an asphalt content of 50%; apply 72g of SBR modified emulsified asphalt evenly on the asphalt mixture rutting slabs, and let it stand for 24 hours ; Use AB glue to stick six 20mm spindles on the surface of the smeared adhesive layer material, and test it after placing it at room temperature for 24 hours. After setting the relevant parameters of the instrument, use the pulling device to pull out, the measuring range is 0.7-20MPa, read the test value, and observe the asphalt adhesion fracture interface. Test results, as shown in Table 1:

[0039] Table 1

[0040]

example 2

[0042] Prefabricated 30cm×30cm×5cm AC-20 asphalt mixture rutting slabs to prepare emulsified asphalt with 50% asphalt content, SBR modified emulsified asphalt and water-based epoxy modified emulsified asphalt. Apply 72g of these three materials evenly on the asphalt rut slab, and let it stand for 24 hours. Use AB glue to stick three groups of 18 20mm spindles on the surface of the smeared adhesive layer material, and place it at room temperature for 24 hours before conducting the test. After setting the relevant parameters of the instrument, use the pulling device to pull out, the measuring range is 0.7-20MPa, read the test value, and observe the asphalt adhesion fracture interface. Test result, as shown in table 2:

[0043] Table 2

[0044]

[0045] From the above test results, it can be concluded that among the three materials, the bond strength of water-based epoxy emulsified asphalt is the largest.

[0046] The advantages of the present invention are:

[0047] 1. Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com