UV dispergation machine

A glue machine and degumming technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of uneven degumming effect, low work efficiency, poor heat dissipation, etc., and achieve stable degumming effect. The effect of small footprint and saving loading and unloading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

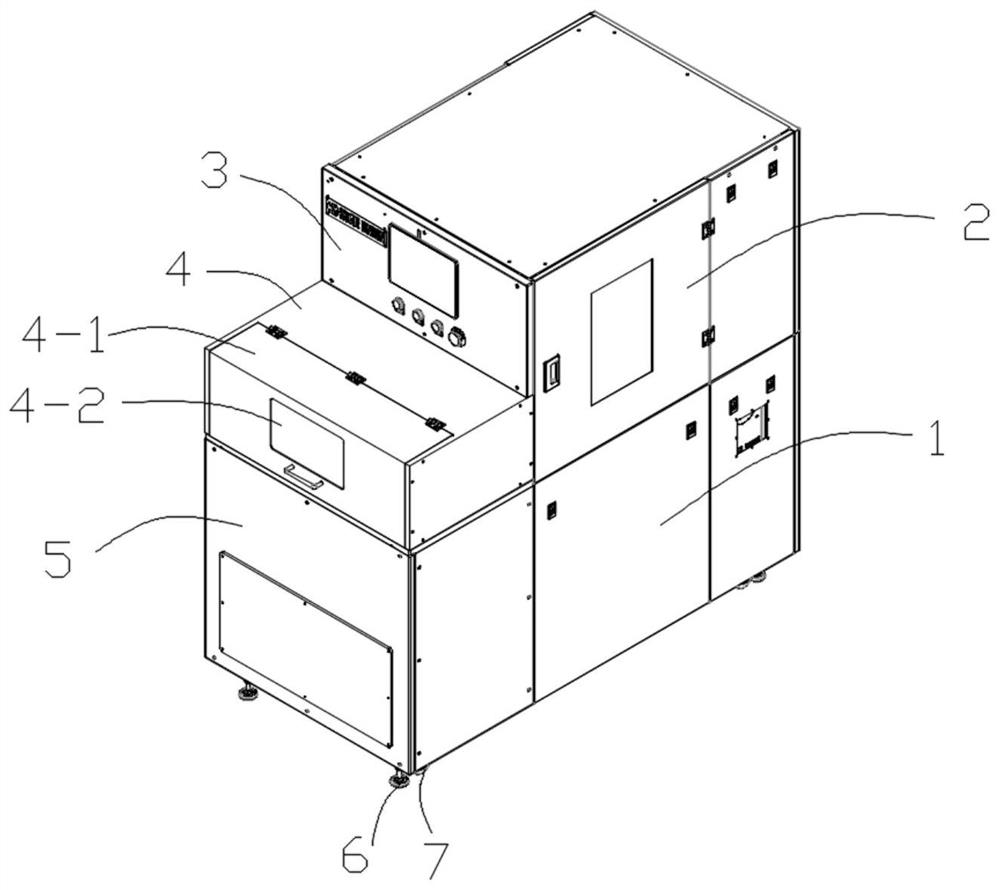

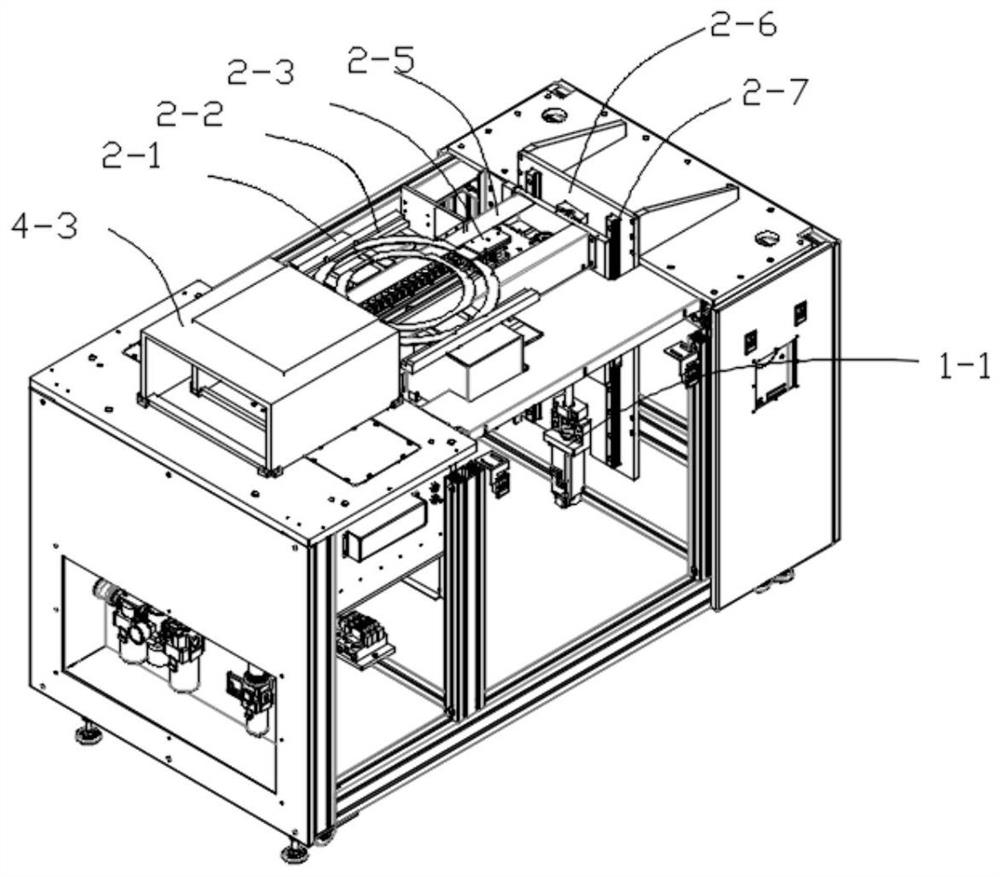

[0029] Such as Figures 1 to 4 As shown, this embodiment provides a UV dissolving machine, which includes an outer casing, a support assembly 6 and a roller assembly 7 arranged at the four corners of the bottom of the outer casing, and the outer casing includes a wafer placement box on the upper left side 4. The main basket box for placing the wafer basket on the upper right side 2. The wafer sub-box on the lower right side for lifting and lowering the wafer basket 1. The deglue box 5 for wafer debonding on the lower left side. The wafer placement box 4, the basket main box 2, the wafer sub-box 1 and the deglue box 5 are sequentially connected, and the wafer placement box 4 is provided with a wafer box 4-3 for placing wafers. The box 2 is provided with a wafer carrier 2-2, a mounting frame 2-5, an adjustment frame 2-1 which is arranged on the mounting frame 2-5 and can adjust the distance of the wafer carrier 2-2, and is arranged on the mounting frame 2-2. 5 and can move hori...

Embodiment 2

[0035] This embodiment is further optimized on the basis of embodiment 1, specifically:

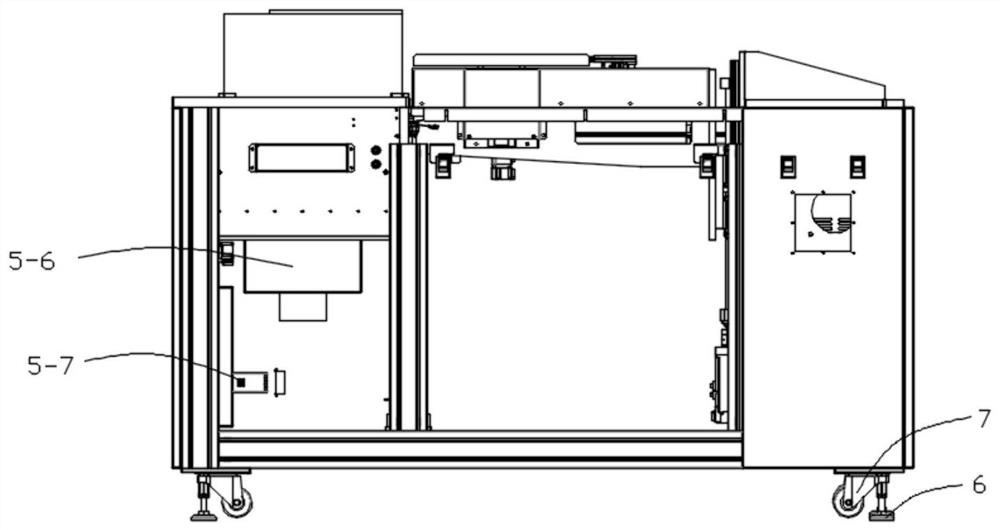

[0036] A nitrogen nozzle 5-4 is arranged on the top of the degumming box 5, and an exhaust fan 5-7 is arranged on the inner bottom of the degumming box 5 to make nitrogen convective.

[0037] A cooling fan is arranged in the degumming box 5 .

[0038] The wafer box 4-3 is a U-shaped folded plate with the opening facing downwards. The width of the U-shaped folded plate is adapted to the width of the wafer basket 2-2. The wafer placement box 4 is provided with an opening. A sealing cover 4-1 is hingedly arranged at the opening, and a transparent observation window 4-2 and a handle are arranged on the sealing cover 4-1.

[0039] A control panel 3 is arranged on the left side of the main box 2 of the carrying basket, and a plurality of control buttons are arranged on the control panel 3 .

[0040] The inner right side wall of the main box 2 of the basket is provided with a vertical guide pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com