Reaction device for bactericide production

A technology of reaction device and bactericide, applied in chemical/physical/physical-chemical fixed reactors, detailed information of chemical/physical/physical-chemical reactors, cleaning methods and utensils, etc. Problems such as air pressure adjustment and single operation mode achieve the effects of convenient cleaning and maintenance, simple and convenient loading and unloading operations, and reducing the loss of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

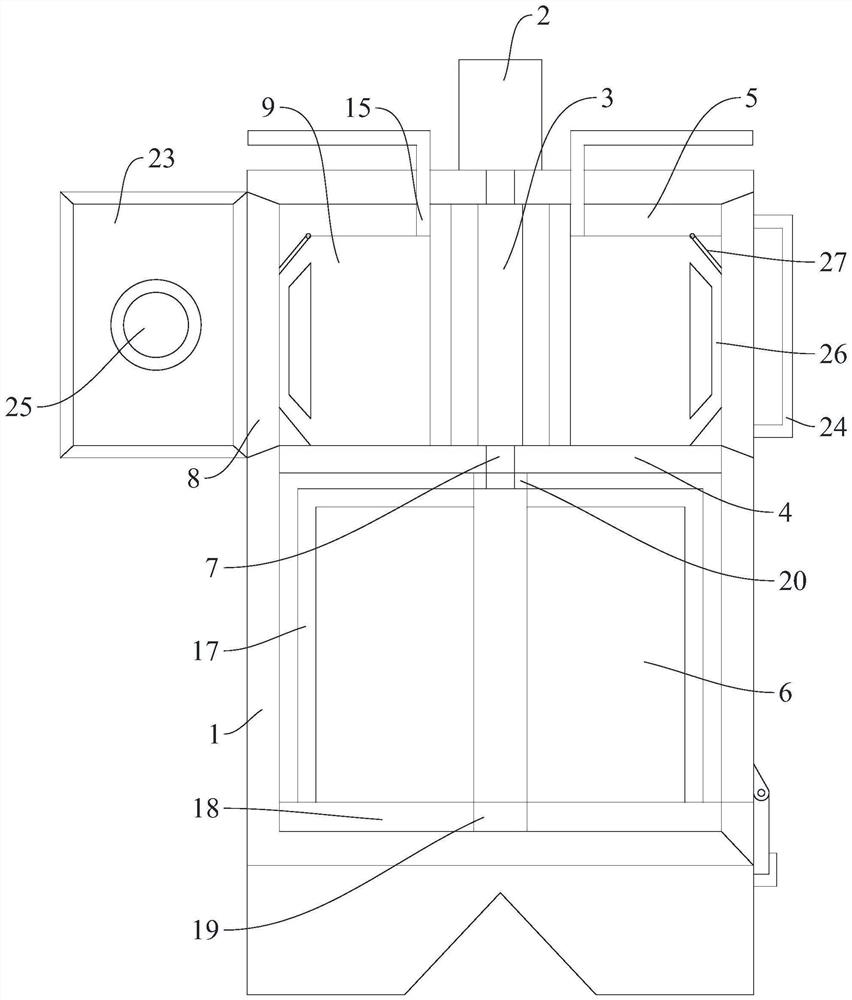

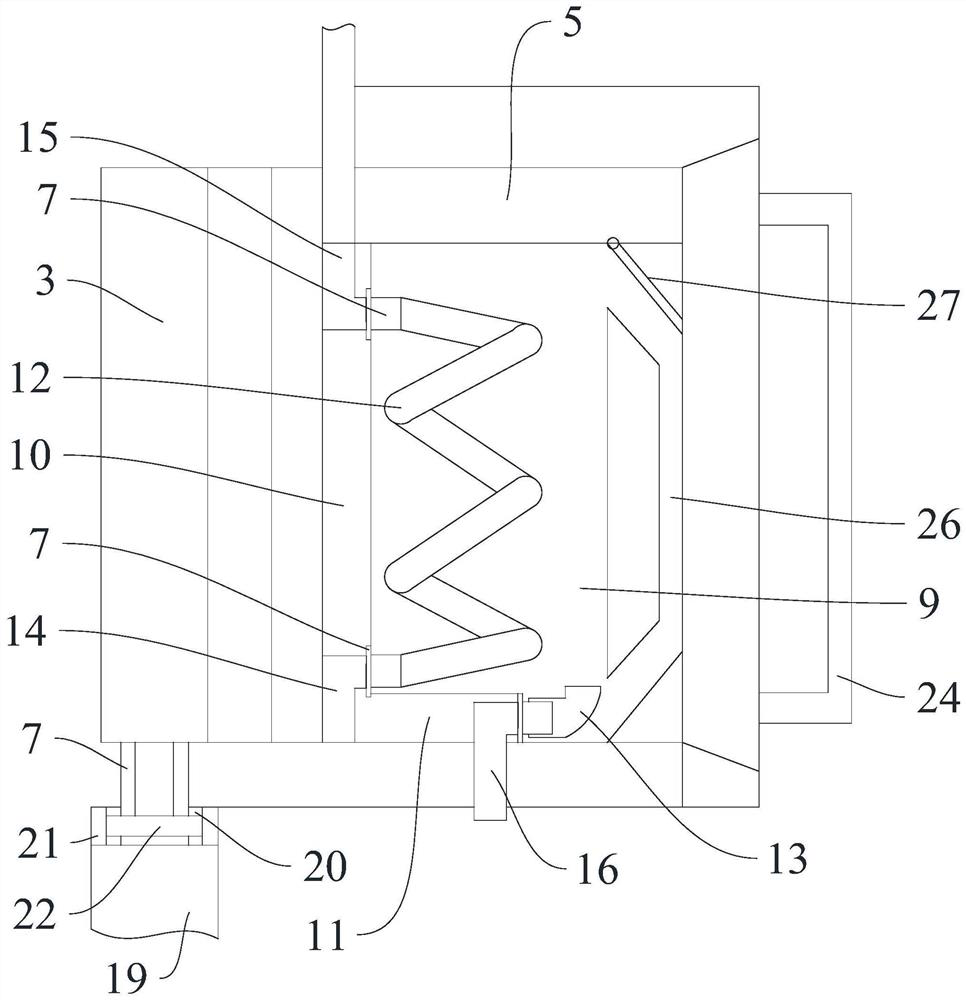

[0027] Embodiment: the top motor 2 control rotation stirring, electric lift pusher 3 to drive lifting. The top motor 2 and the electric lift pushrod 3 are powered by an external power supply and controlled by an external switch.

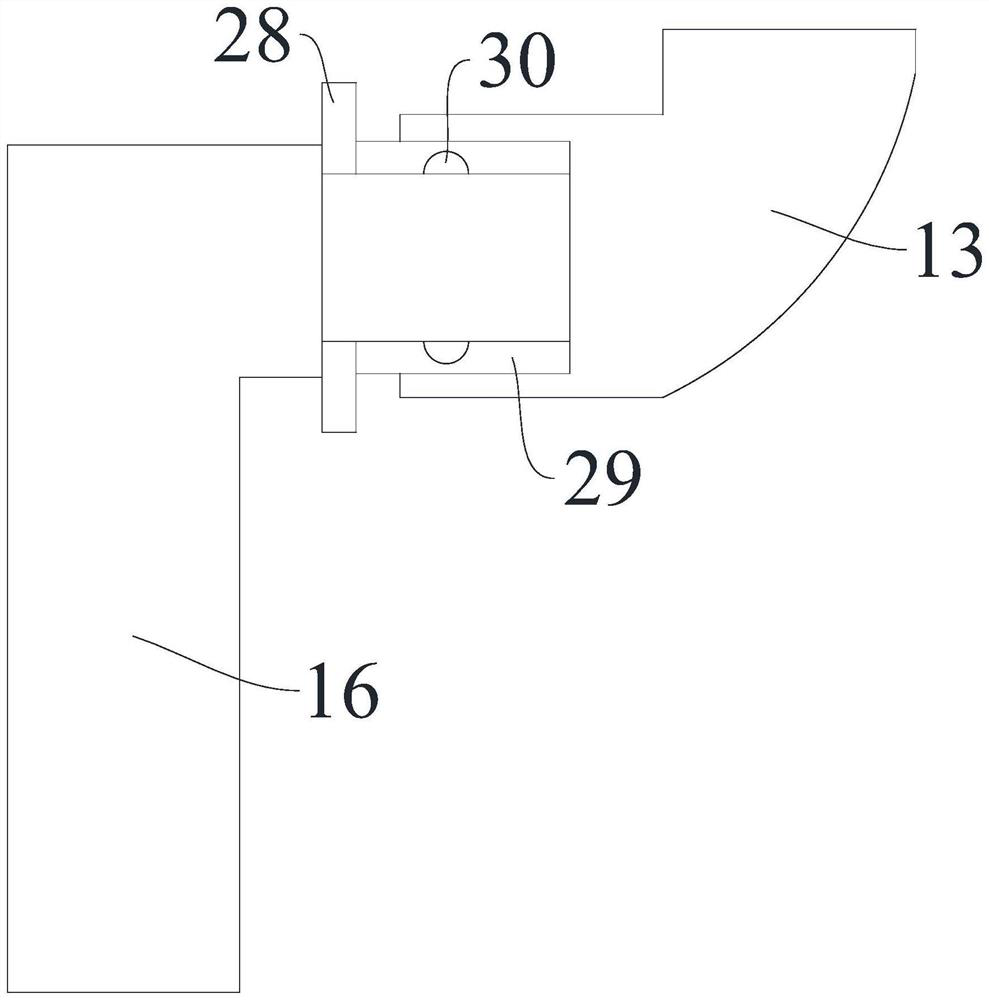

[0028]Further, in order to facilitate the control of stirring and centrifugal scraping, the height adjustable bottom stirring centrifugal apparatus comprises an axially fixed axially fixed at the bottom end of the longitudinal drive shaft 7 bottom structure bottom transmission frame 17, a lateral stirring separation vane 18 fixed on the inner side of the bottom drive frame 17, a lateral linkage plate 19 fixed on the outer side of the transverse stirring separation vane 18 and an external control sleeve 20 fixed on the lateral linkage plate 19, an external control sleeve 20 active sleeve 7 outer side of the longitudinal transmission shaft, further, In order to cooperate with the electric lift control, the bottom lifting rod 3 of the electric lifting push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com