Metal injection molding mechanism and injection molding machine

An injection molding, metal technology, applied in the field of metal injection molding devices, to achieve the effect of simple operation, wide applicability and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

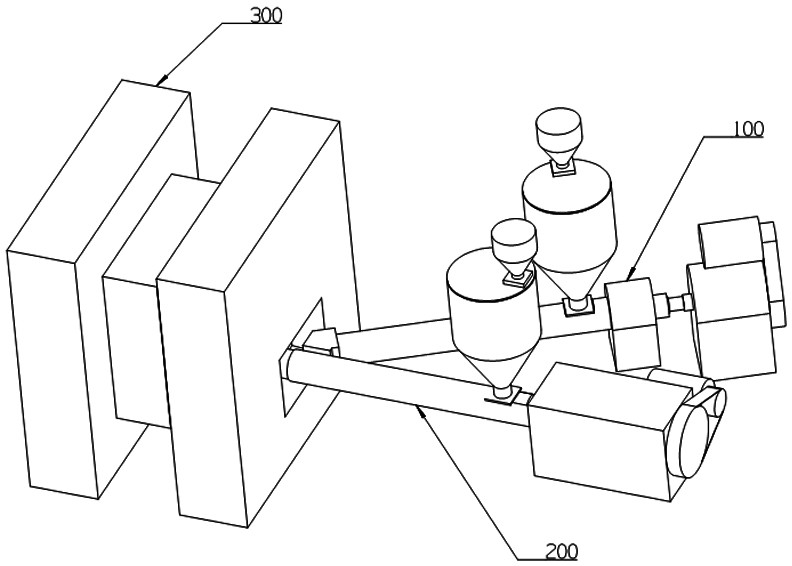

[0034] A metal injection molding mechanism provided in this embodiment or a metal injection molding machine with the mechanism includes an injection unit 100, an injection unit 200, and a mold 300. figure 1 It shows that the injection unit 200 is directly connected to the mold 300, while the injection unit 100 is connected to the injection unit 200, and the melt outlet of the injection unit 100 is connected to the injection front end of the injection unit 200. .

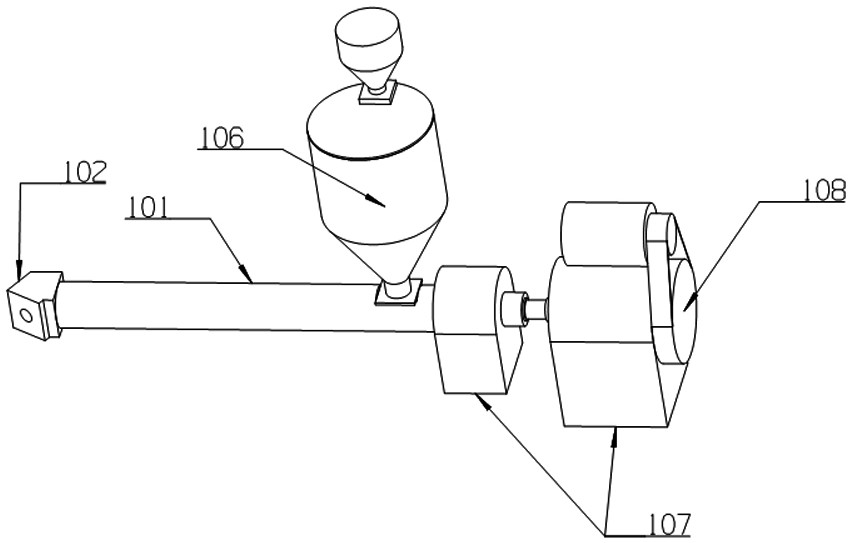

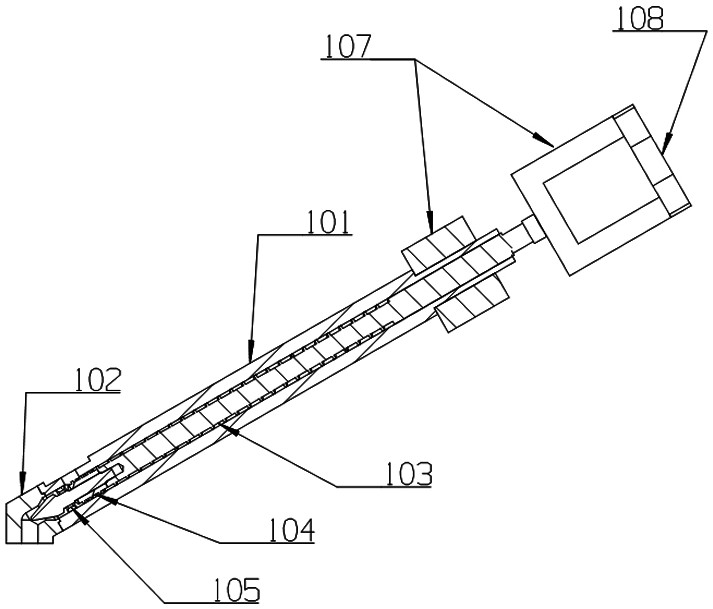

[0035] as attached figure 2 , 3 As shown, the injection unit 100 includes a material cylinder 101 and a discharge pipe 102 arranged at the end of the material cylinder 101 (the discharge pipe 102 is connected to the front end of the injection cylinder 201 or the front barrel 202 described below) , the feeding screw 103 arranged in the material barrel 101, the drying bin 106 arranged on the material barrel 101 and used to supply the melt, and the end of the material barrel 101 away from the discharge pipe 102 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com