Automatic powder collecting and feeding system for metal powder 3D printing and printing method

A technology of metal powder and 3D printing, applied in metal processing equipment, transportation and packaging, additive manufacturing, etc., can solve problems such as waste of resources, impact on cost and molding efficiency, abandonment, etc., to improve safety, stability and sustainability Improve workability and print efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

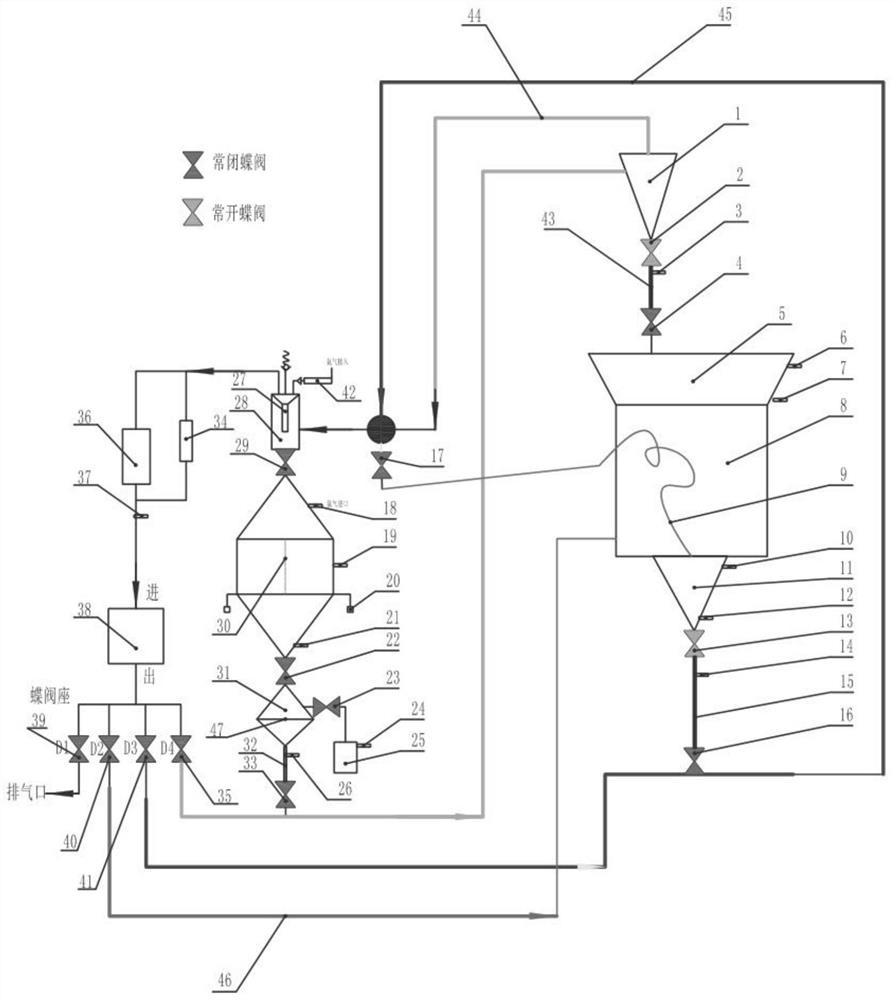

[0040] A metal 3D printing vacuum automatic powder feeding system, including a cyclone separator 1, a printer silo 5, a printer printing chamber 8, and a waste powder tank 11 arranged sequentially from top to bottom, and the cyclone separator 1 passes through a powder supply pipeline 44 It is connected to the powder tank 30, and the powder supply pipeline 45 is connected to the bottom of the powder tank 30. The waste powder tank 11 is connected to the powder tank 30 through the waste powder pipeline 45, and the waste powder is sent into the powder tank 30 for reuse.

[0041] The powder tank 30 is provided with an argon gas inlet 18, a powder tank high powder level sensor switch 19, a load cell assembly 20 and a powder tank low powder level sensor switch 21 from top to bottom. The butterfly valve 29 is connected to the exhaust barrel 28, and the filter element 27 is arranged in the exhaust barrel 28. The exhaust barrel 28 is connected to the cyclone separator 1 through the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com