Automatic device for separating attachments on surfaces of positive and negative pole pieces of waste power lithium battery

An automatic device, a technology of positive and negative plates, applied in the direction of grinding drive device, grinding/polishing safety device, grinding feed movement, etc., can solve the problems of increasing the workload of separation work, large dust in the working environment, damage and other problems , to achieve the effect of facilitating direct recycling, continuous production operations, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

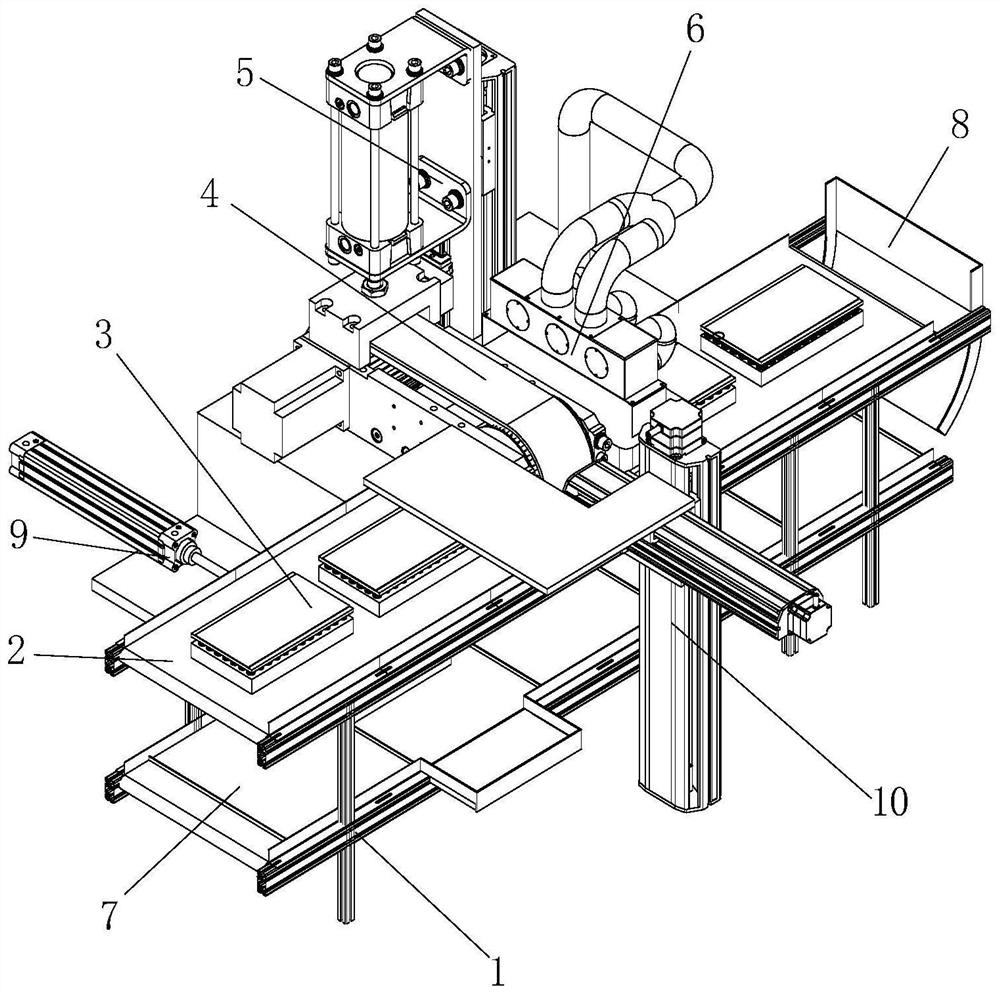

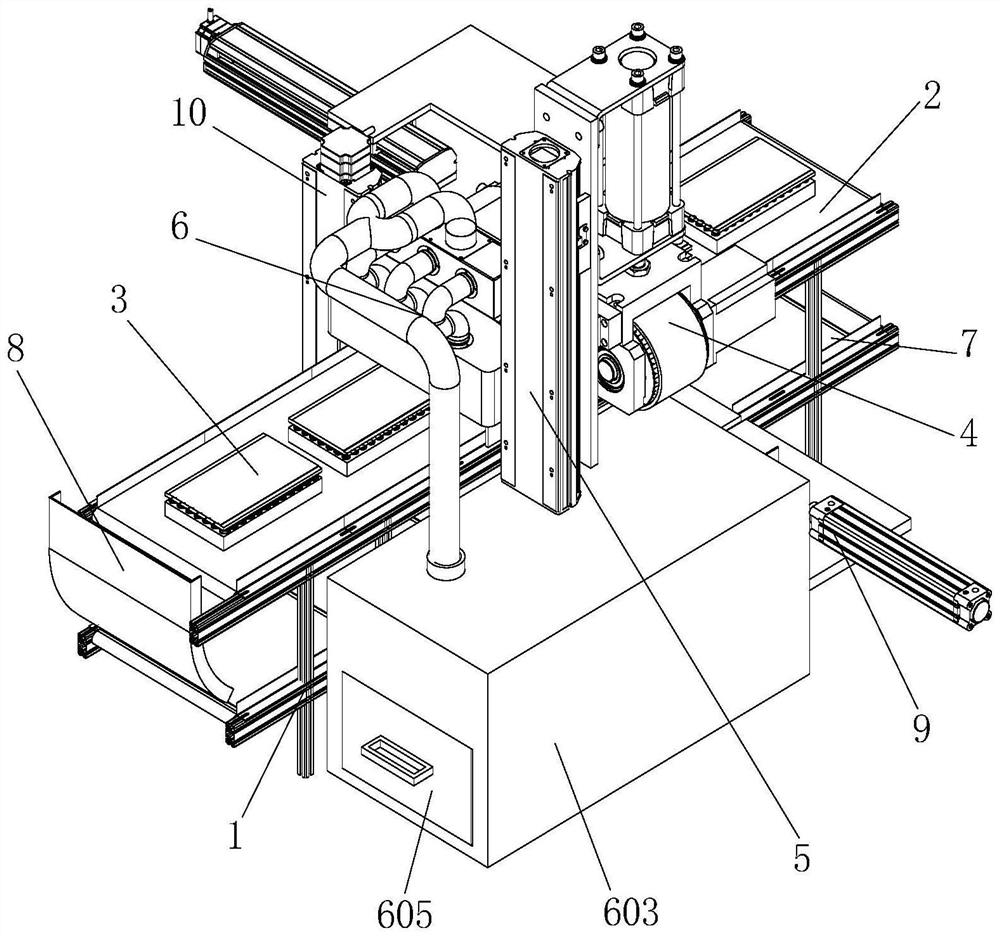

[0043] see Figure 1 to Figure 12 , an automatic device for separating the surface attachments of the positive and negative plates of waste power lithium batteries, including a frame 1, the frame 1 is a frame structure assembled from aluminum alloy profiles, and is fixedly connected by bolting or welding.

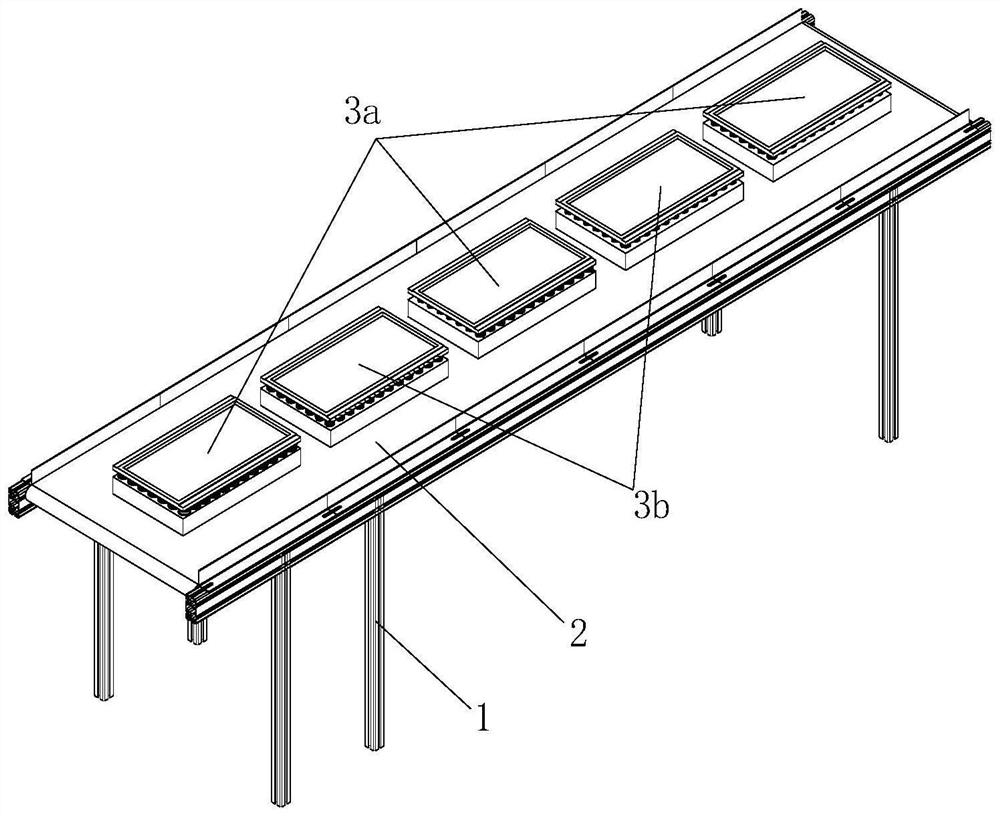

[0044] like image 3 As shown, the top of the frame 1 is provided with a feeding conveyor belt device 2 for feeding the battery pole pieces to be processed. The feeding conveyor belt device 2 adopts a non-slip synchronous belt conveyor device and is driven by a stepping motor or a servo motor to realize a single fixed-distance progressive con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com