Automatic drilling machine capable of feeding

A drilling machine and automatic technology, applied in fixed drilling machines, manufacturing tools, wood processing equipment, etc., can solve the problems of high labor dependence, low automation, and low processing efficiency, and achieve low labor dependence and automation High, high processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

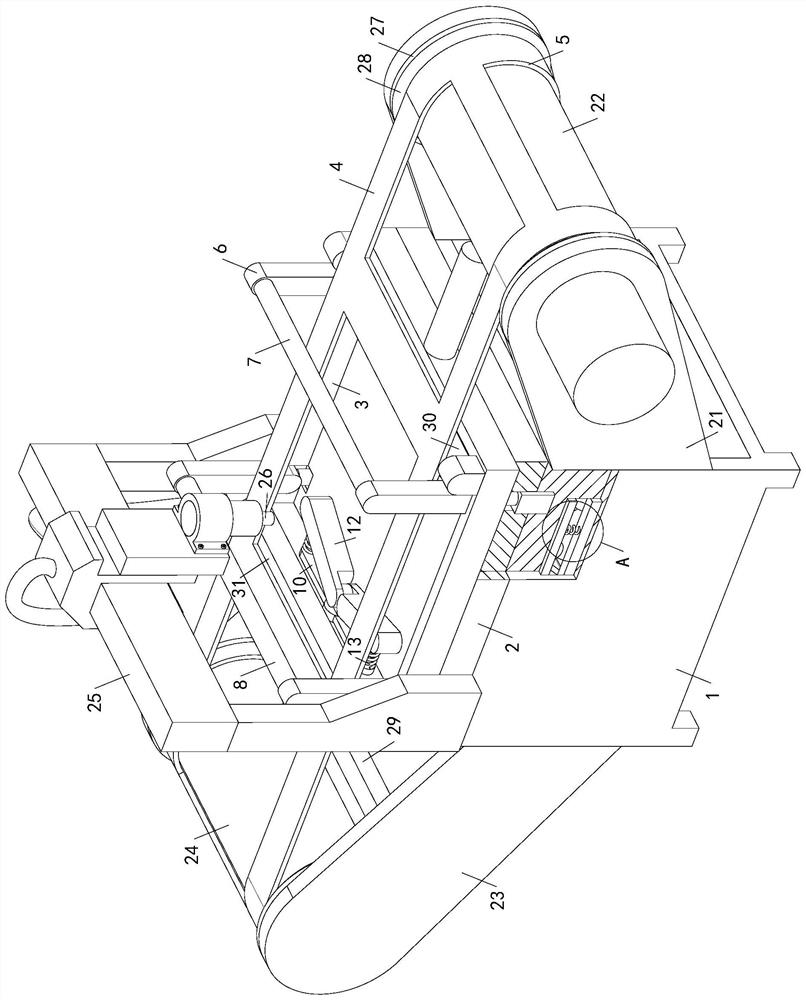

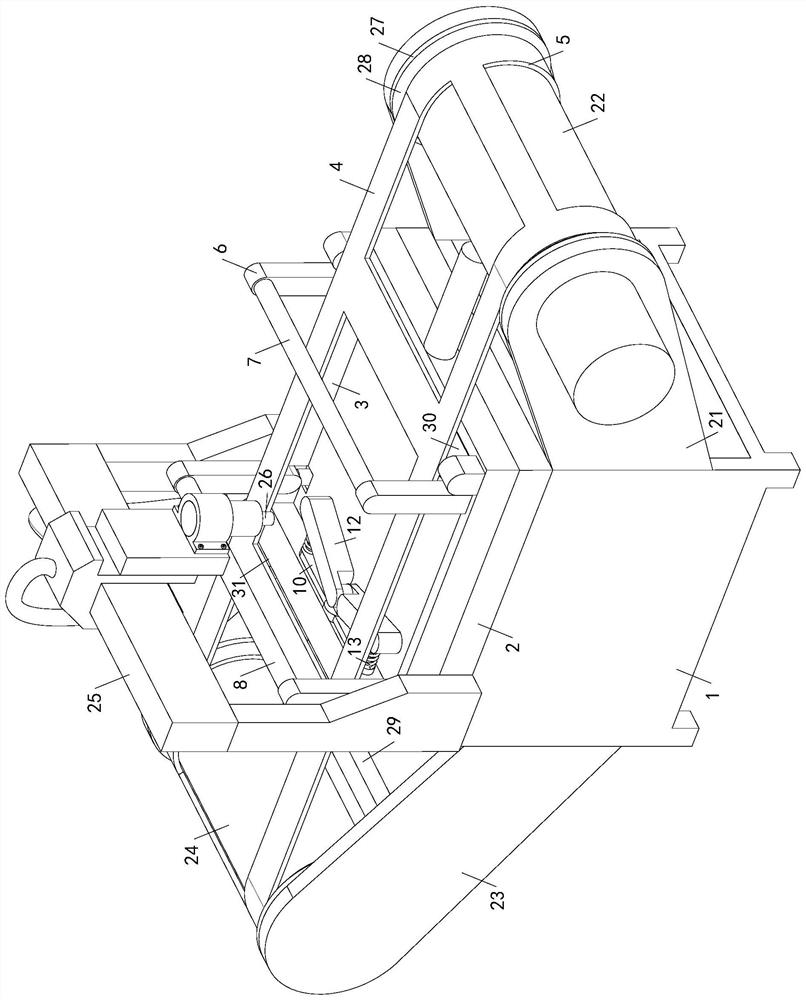

[0031] see Figure 1-5, an automatic drilling machine capable of loading materials, comprising an automatic drilling machine body 1, a workbench 2 is arranged on the automatic drilling machine body 1, a sawdust collection device 3 is installed on the workbench 2, and an assembly line conveyor belt 4 is also included, The front end of the automatic drilling machine body 1 is equipped with a main roller assembly, and the rear end of the automatic drilling machine body 1 is equipped with a slave roller assembly. The main roller assembly includes two front plate frames 21, and the two front plate frames 21 are fixedly connected to the The front end of the automatic drilling machine body 1 is rotatably connected with a drive roller 22 connected to the assembly line conveyor belt 4 between the two front frames 21, and a drive roller 22 is installed on one of the two front frames 21 for the drive roller. 22 driven drive motors, the roller assembly includes two back plates 23, the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com