Coal mine belt intelligent monitoring system and monitoring method thereof

An intelligent monitoring and belt technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of low work efficiency, time-consuming and laborious, frequent maintenance and replacement of devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The best embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

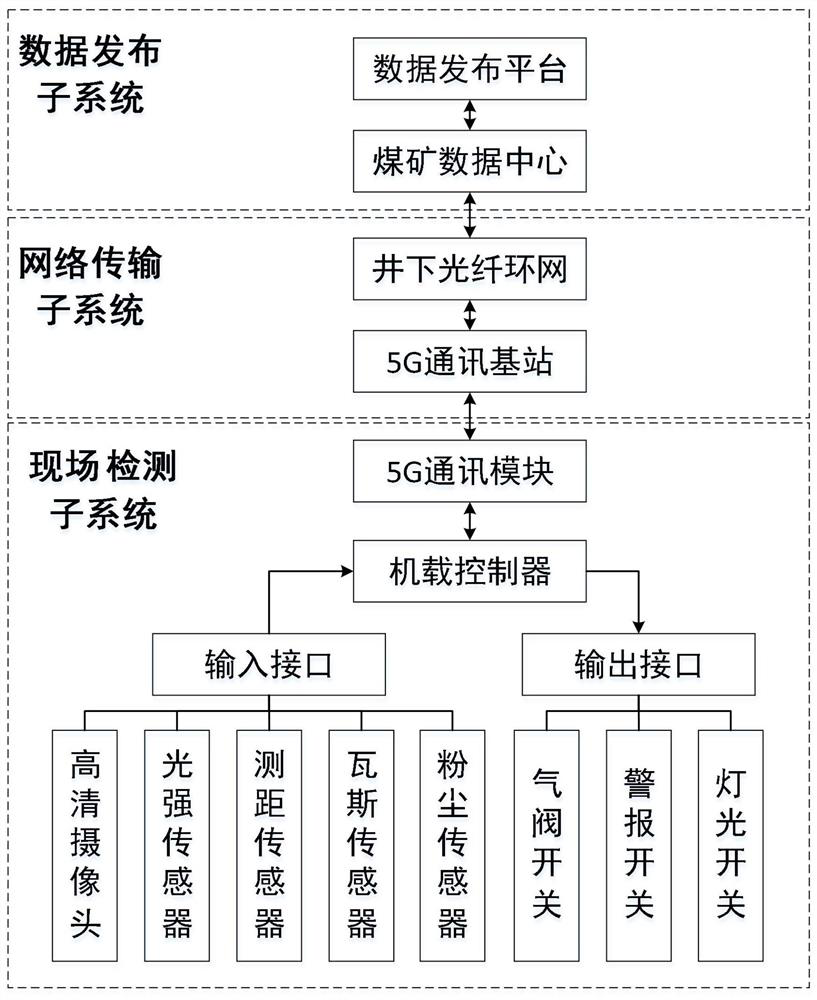

[0062] Such as figure 1 As shown, a coal mine belt intelligent monitoring system includes three parts: on-site detection subsystem, network transmission subsystem, and data release subsystem. The on-site detection subsystem and network transmission subsystem are connected through a 5G wireless network and To transmit data, the network transmission subsystem and the data publishing subsystem are connected through optical fiber to transmit data.

[0063] The on-site detection subsystem includes: a high-definition camera, a light intensity sensor, a distance sensor, a gas sensor, a dust sensor, a gas valve switch, an alarm switch, and a light switch;

[0064] Among them, the high-definition camera is connected to the input interface and transmits data through a 2×10DIP interface, the light intensity sensor is connected to the input interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com