Heat-insulating constant-temperature energy-saving ceramic tile and production process thereof

A production process and ceramic tile technology, which is applied in the field of ceramic tiles, can solve the problems of poor thermal insulation effect and high thermal conductivity of ceramic tiles, and achieve the effects of preventing moths, increasing the contact area, and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

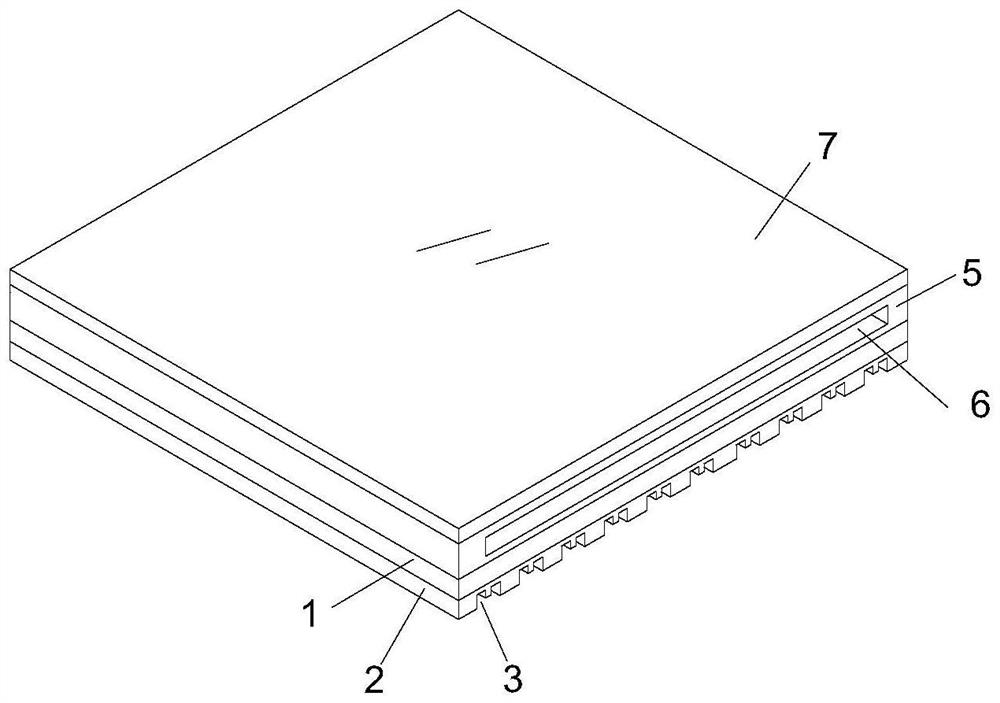

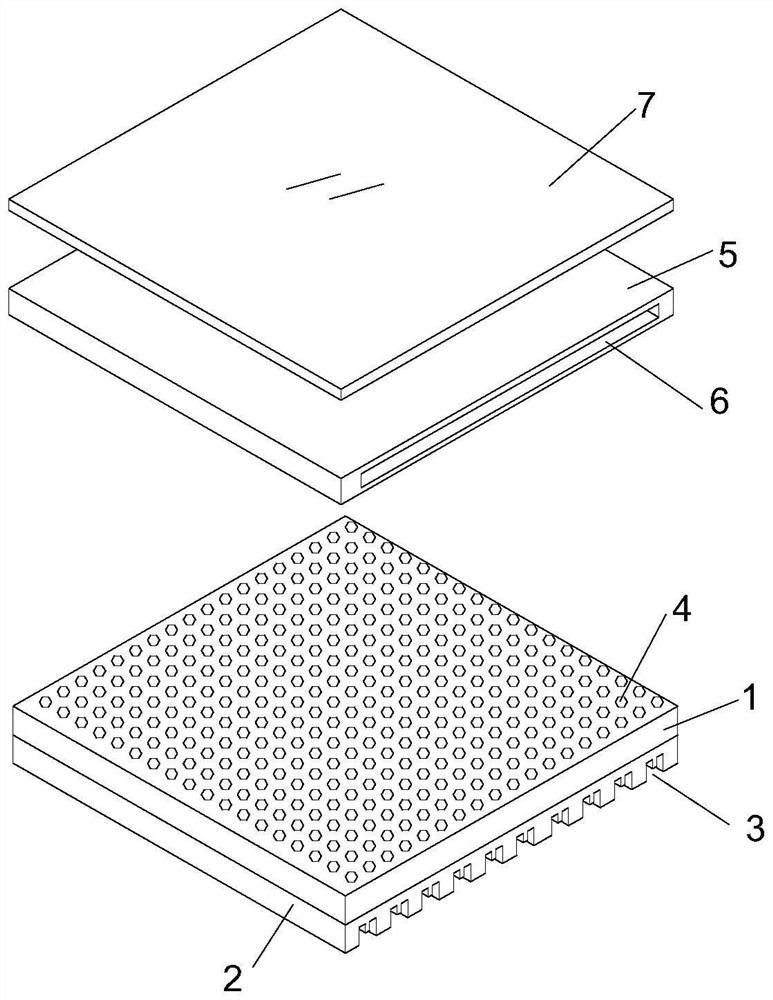

[0038] Embodiment: a kind of thermal insulation constant temperature energy-saving ceramic tile, such as Figure 1-Figure 2As shown, the tile body 1 is included, and the bottom surface of the tile body 1 is parallelly laid with a tile bottom layer 2, and a side of the tile bottom layer 2 away from the tile body 1 is equidistantly provided with multiple groups of grooves 3, and the tile body 1 is away from the tile bottom layer. There are multiple sets of intensive holes 4 on one side of the 2, and the multiple sets of intensive holes 4 are densely and evenly distributed on the top surface of the tile body 1, and the ceramic tile body 1 is hollowed out and loose through the multiple sets of dense holes 4 opened. The top surface of the ceramic tile body 1 is fixedly laid with an insulating layer 5, and an interlayer 6 is formed on the side wall surface of the insulating layer 5, and the interior of the interlayer 6 is filled with insulating material, which is made of a mixture of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com