Method for preparing 5-substituted tetrazole compound and product obtained by method

A compound, tetrazolium technology, applied in the field of preparation of 5-substituted tetrazolium compounds, can solve the problems of complex post-processing operations, long reaction time, low reactivity, etc., achieve simplified separation and purification steps, and reduce reaction time , The effect of reducing the amount of catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

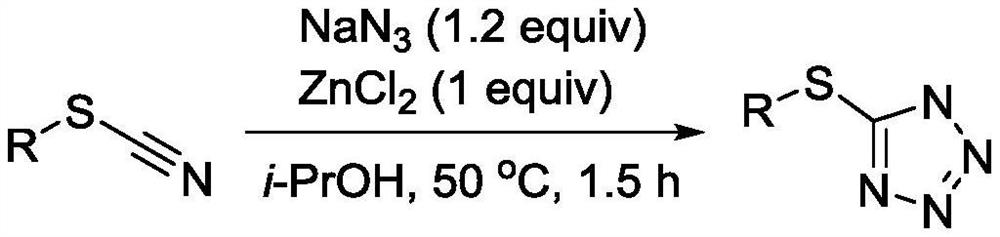

Method used

Image

Examples

Embodiment 1

[0047]

[0048] A kind of preparation method of 5-substituted tetrazole compound II-1, its steps are:

[0049] A. Add ethyl thiocyanate (0.1mol, 8.7g), sodium azide (0.12mol, 7.8g) and water (300ml) in the reaction vessel, fully stir at room temperature to obtain a mixed solution;

[0050] B. add chitosan immobilized zinc catalyst (10.0mg) in the mixed solution in A;

[0051] C. stirring reaction at room temperature, the reaction time is 1h;

[0052] D. Add hydrobromic acid dropwise to the mixed solution obtained in step C, adjust the pH to about 1;

[0053] E. filtering and separating the solid catalyst;

[0054] F. Cool the clear solution (upper layer) separated in step E to below 5°C, and recrystallize to obtain 12.0 g of 5-ethylthiotetrazolium compound II-1, with a yield of 92%;

[0055] G. The chitosan immobilized zinc catalyst that reclaims, recyclable, reclaims 9.9mg altogether, reclaims the productive rate that carries out reaction for seven times and is respecti...

Embodiment 2

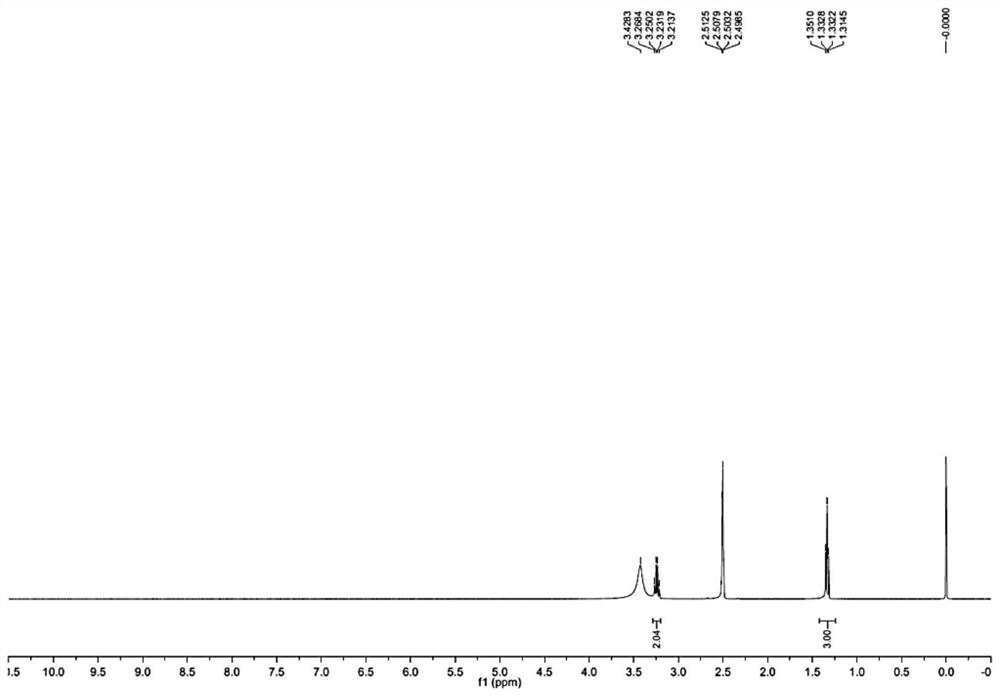

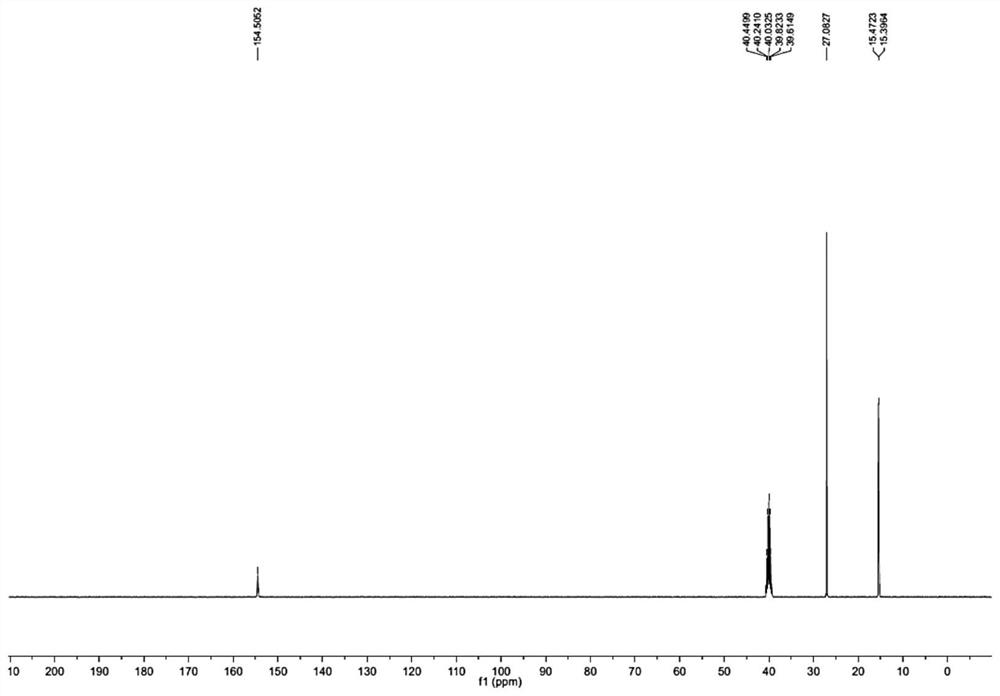

[0060]

[0061]A kind of preparation method of 5-substituted tetrazole compound II-2, its steps are:

[0062] A. Add methyl thiocyanate (0.1mol, 7.3g), sodium azide (0.12mol, 7.8g) and water (300ml) in the reaction vessel, fully stir at room temperature to obtain a mixed solution;

[0063] B. add chitosan immobilized zinc catalyst (10mg) in the mixed solution in A;

[0064] C. stirring reaction at room temperature, the reaction time is 0.5h;

[0065] D. Add hydrobromic acid dropwise to the mixed solution obtained in step C, adjust the pH to about 1;

[0066] E. filtering and separating the solid catalyst;

[0067] F. Cool the clear solution (upper layer) separated in step E to below 5°C, and recrystallize to obtain 10.2 g of 5-methylthiotetrazolium compound II-2, with a yield of 93%;

[0068] G. The chitosan immobilized zinc catalyst that reclaims, recyclable, reclaims 9.2mg altogether, reclaims the productive rate that carries out reaction for seven times and is respect...

Embodiment 3

[0073]

[0074] A preparation method of 5-substituted tetrazole compound II-3, the steps are:

[0075] A. Add phenyl thiocyanate (0.1mol, 13.5g), sodium azide (0.12mol, 7.8g) and water (300ml) in the reaction vessel, fully stir at room temperature to obtain a mixed solution;

[0076] B. add chitosan immobilized zinc catalyst (10mg) in the mixed solution in A;

[0077] C. stirring reaction at room temperature, the reaction time is 0.5h;

[0078] D. Add hydrobromic acid dropwise to the mixed solution obtained in step C, adjust the pH to about 1;

[0079] E. filtering and separating the solid catalyst;

[0080] F. Cool the clear solution (upper layer) separated in step E to below 5°C, and recrystallize to obtain 16.9 g of 5-phenylthiotetrazolium compound II-3, with a yield of 95%;

[0081] G. The chitosan immobilized zinc catalyst that reclaims, recyclable, reclaims 9.2mg altogether, reclaims the productive rate that carries out reaction for seven times and is respectively:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com