Coating composition and method for controlling speed of cross-linking reaction thereof

A composition and coating technology, applied in the direction of coating, etc., can solve the problem of high activation energy, achieve the effects of expanding the application range, solving the problem of short construction time and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

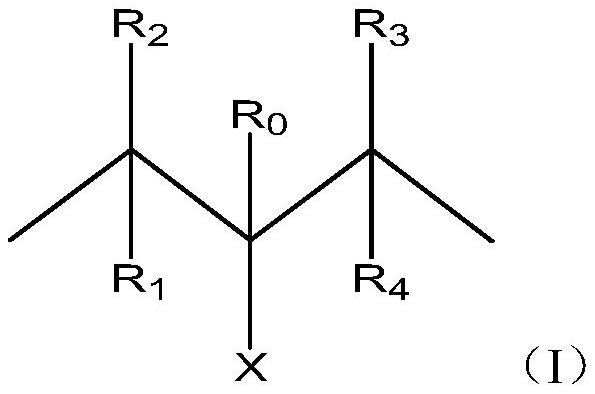

Method used

Image

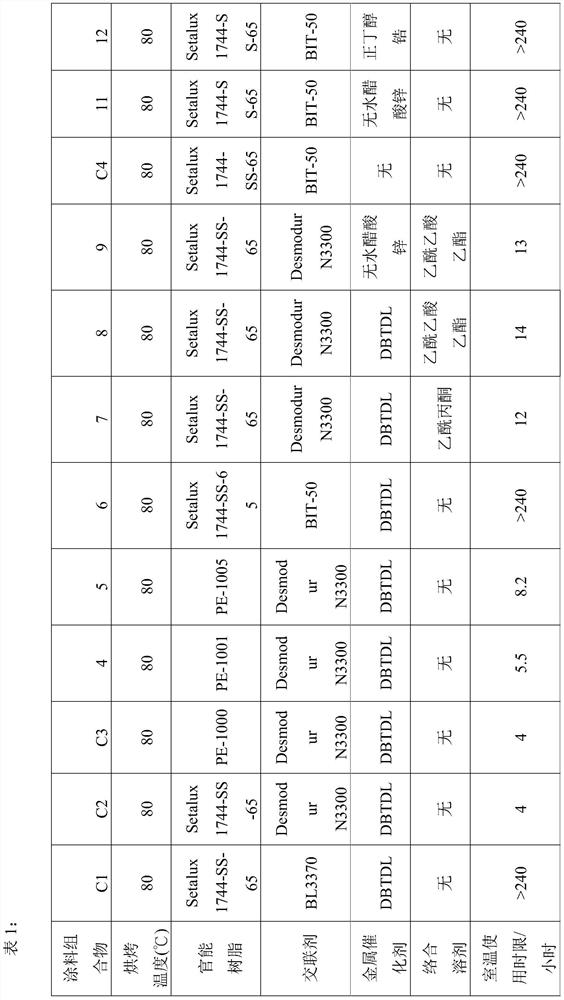

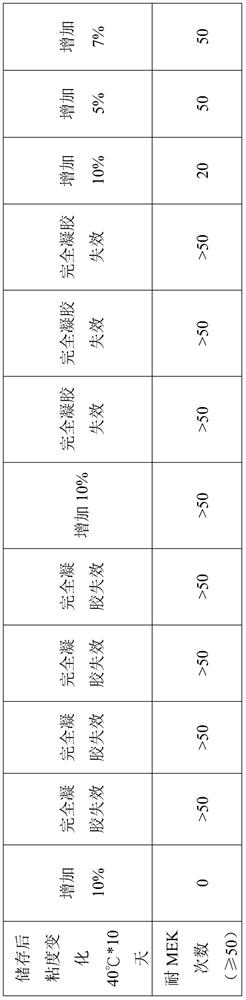

Examples

Embodiment 4

[0081] Embodiment 4 prepares coating composition 4

[0082] First synthesize the main resin PE-1001. React 25.75g of ε-caprolactone, 0.64g of stannous isooctanoate, 1.96g of 1,2 propylene glycol and 25.00g of xylene in an oil bath at 140°C for 24 hours. After testing the residual acid value < 5, cool to obtain PE-1001 resin. The hydroxyl ortho position of the main resin PE1001 has methyl steric hindrance.

[0083] Coating composition 4 was prepared by mixing 63.0 g of PE-1001 resin, 23.0 g of crosslinker isocyanate Desmodur N 3300, 13.3 g of butyl acetate, 0.2 g of BYK-306, and 0.5 g of DBTDL at room temperature for 30 minutes. The coating composition 4 is a two-component system.

[0084] Use a 150um scraping rod to coat the coating composition 4 on the substrate, and bake at 80°C for 30 minutes to obtain the paint film of the coating composition 4.

Embodiment 5

[0085] Embodiment 5 prepares coating composition 5

[0086] First synthesize the main resin PE-1005. React 25.75g of ε-caprolactone, 0.64g of stannous isooctanoate, 3.05g of 1,2 hexanediol and 25.00g of xylene in an oil bath at 140°C for 24 hours. After testing the residual acid value <5, cool to obtain PE- 1005 resin. The hydroxyl ortho position of the main body resin PE1005 has n-pentyl steric hindrance.

[0087] Coating composition 5 was prepared by mixing 63.0 g of PE-1005 resin, 23.0 g of crosslinker isocyanate Desmodur N 3300, 13.3 g of butyl acetate, 0.2 g of BYK-306, and 0.5 g of DBTDL at room temperature for 30 minutes. The coating composition 5 is a two-component system.

[0088] Use a 150um scraping bar to coat the coating composition 5 on the substrate, and bake at 80°C for 30 minutes to obtain the paint film of the coating composition 5.

Embodiment 6

[0089] Embodiment 6 prepares coating composition 6

[0090] First prepare the blocked cross-linking agent BIT-50, the steps are as follows:

[0091] (1) 50g isocyanate trimer, 18g cyclohexanone, 20g xylene, 25g methyl ethyl ketone, 0.3g DBTDL, to generate isocyanate solution. Wherein, the isocyanate-containing trimer may be one or more selected from HDI trimer, TDI trimer, MDI trimer, and IPDI trimer.

[0092] (2) Heat the above-mentioned isocyanate solution to 45°C, and gradually add the blocking agent dropwise at a speed of 500 to 800 rpm, keeping the ratio of the hydroxyl group of the blocking agent and the NCO group of the isocyanate in the range of 1:1 to 3:1, and the blocking agent is kept for 2 hours. After dripping, keep the temperature for 0.5h and then slowly raise the temperature to 70-75°C;

[0093] Wherein, the blocking agent can be selected from methyl ethyl ketone oxime, acetone oxime, 3,5-dimethylpyrazole, 2-methylimidazole, acetylacetone, ethyl acetoacetat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com