High earth and rockfill dam anti-seepage earth material blending construction method

A technology for high earth-rock dams and construction methods, which is applied in the direction of dams, barrages, and infrastructure engineering, etc. It can solve the problems that the soil materials in the stockyard cannot meet the design requirements, etc., so as to facilitate on-site construction operations, simple mixing process, and improve construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

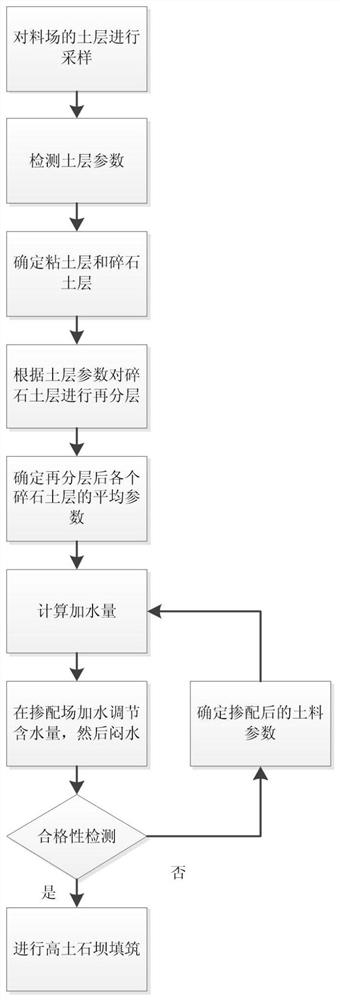

Embodiment 1

[0066] This embodiment is aimed at a high earth-rock dam anti-seepage soil mixing construction method aimed at the natural gradation of crushed stone soil in the stockyard meeting the requirements and the preparation strength of the crushed stone soil meeting the requirements, including:

[0067] The first step is to determine the location of the stockyard, and conduct vertical sampling of the soil layer of the stockyard. In order to facilitate clear measurement, repeated sampling can be carried out at multiple locations to facilitate accurate sampling.

[0068] In the second step, based on the sampling data, the parameters of the soil layer are detected, including water content, P5 content, clay content, and bulk density. In this step, relevant data can be measured in the laboratory through traditional methods.

[0069] The third step is to determine the clay layer and gravel soil layer, and divide the clay layer and gravel soil layer according to the measured P5 content and c...

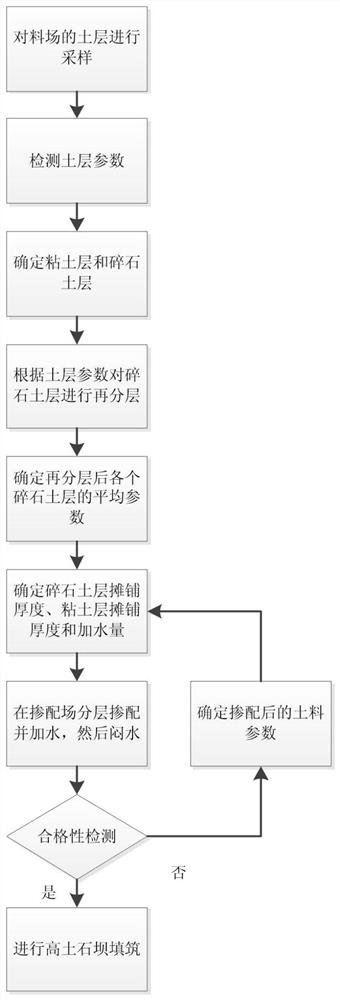

Embodiment 2

[0085] According to the mining situation in the soil material field, combined with the sampling test results of the soil material, when the natural gradation of the gravel soil cannot meet the requirements, the natural grades of the clay layer and the gravel soil layer obtained by sampling the corresponding production area in the soil material field Mixing and water content, this embodiment is a high earth-rock dam anti-seepage soil mixing construction method for the natural gradation of gravel soil in the stockyard that does not meet the requirements but the strength of the crushed soil preparation meets the requirements, including:

[0086] The first step is to determine the location of the stockyard and sample the soil layer in the vertical direction;

[0087] In the second step, according to the sampling data, the parameters of the soil layer are detected, including water content, P5 content, clay content, and bulk density;

[0088] The third step is to determine the clay ...

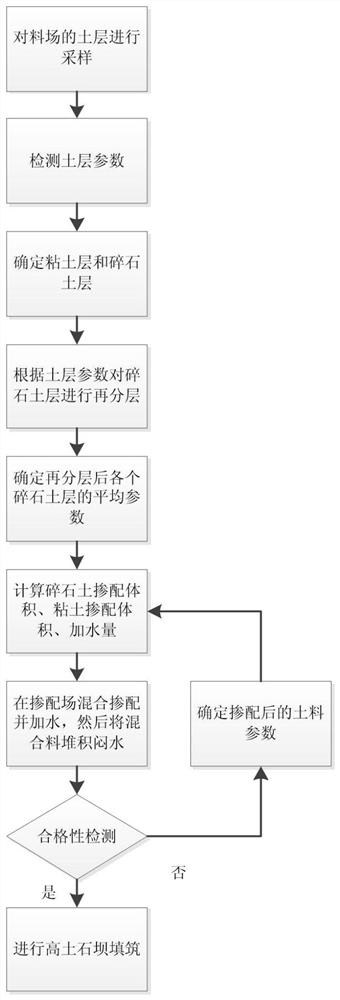

Embodiment 3

[0107] This embodiment is a high earth-rock dam anti-seepage soil mixing construction method for the natural gradation of gravel soil in the stockyard that does not meet the requirements and the strength of the crushed soil preparation does not meet the requirements, including:

[0108] The first step is to determine the location of the stockyard and sample the soil layer in the vertical direction;

[0109] In the second step, according to the sampling data, the parameters of the soil layer are detected, including water content, P5 content, clay content, and bulk density;

[0110] The third step is to determine the clay layer and gravel soil layer;

[0111] The fourth step is to set the value range of the soil layer parameters, and re-layer the gravel soil layer in the stockyard according to the value range;

[0112] The fifth step is to determine the average parameters of each gravel soil layer after delamination in the stockyard; the setting strength of gravel soil preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com