Antirust oil composition used for metal processing and preparation method thereof

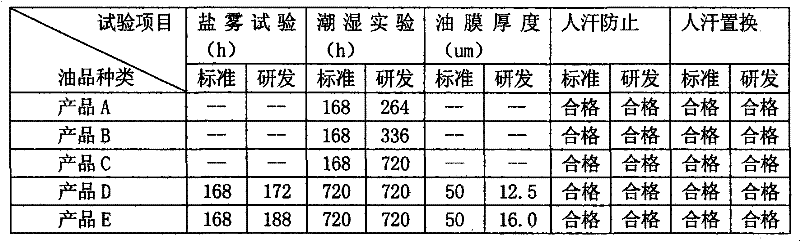

A metal processing and composition technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve problems such as thick oil film, poor anti-rust effect of anti-rust oil, difficult to remove, etc., and achieve breakthrough and excellent performance and effect Effect of anti-salt spray, excellent anti-humidity and anti-rust function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 30kg of lubricating oil 75SN into the kettle, raise the temperature to 80°C, then add 104kg of barium petroleum sulfonate T701, 52kg of oxidized petroleum ester barium soap T743, after it dissolves, add 13kg of sorbitol monooleate SP -80, 1kg of benzotriazole T706, stirred for 2 hours, after filtering, it is the A product of the anti-rust oil composition of the present invention, get A product 4kg and dilute with 196kg 120# solvent oil, ready to use.

Embodiment 2

[0024] Add 32kg of lubricating oil 150SN into the kettle, raise the temperature to 90°C, then add 102kg of petroleum sodium sulfonate T702, 56.6kg of lanolin magnesium soap, and after it dissolves, add 9kg of alkenyl succinate T747, 0.4 kg of tolyltriazole was stirred for 3 hours, and after filtering, it was the B product of the antirust oil composition of the present invention, and 6 kg of the B product was diluted with 194kg 120# solvent oil to get ready to use.

Embodiment 3

[0026] Add 40kg of lubricating oil 350SN into the kettle, heat up to 100°C, then add 75kg of petroleum calcium sulfonate T101, 70kg of lanolin aluminum soap, after it dissolves, add 14kg of glycerol borate fatty acid ester, 1kg of ethyl benzotriazole was stirred for 2.5 hours, and after filtering, it was the C product of the antirust oil composition of the present invention, and 8 kg of the C product was diluted with 192kg of 120# solvent oil to be ready for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com