Coal mine drilling depth measuring nipple and drilling depth determining method

A technology for drilling depth and sub-section measurement, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc. It can solve the problems of large hole depth measurement error and achieve the effects of strong adaptability, accurate determination and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

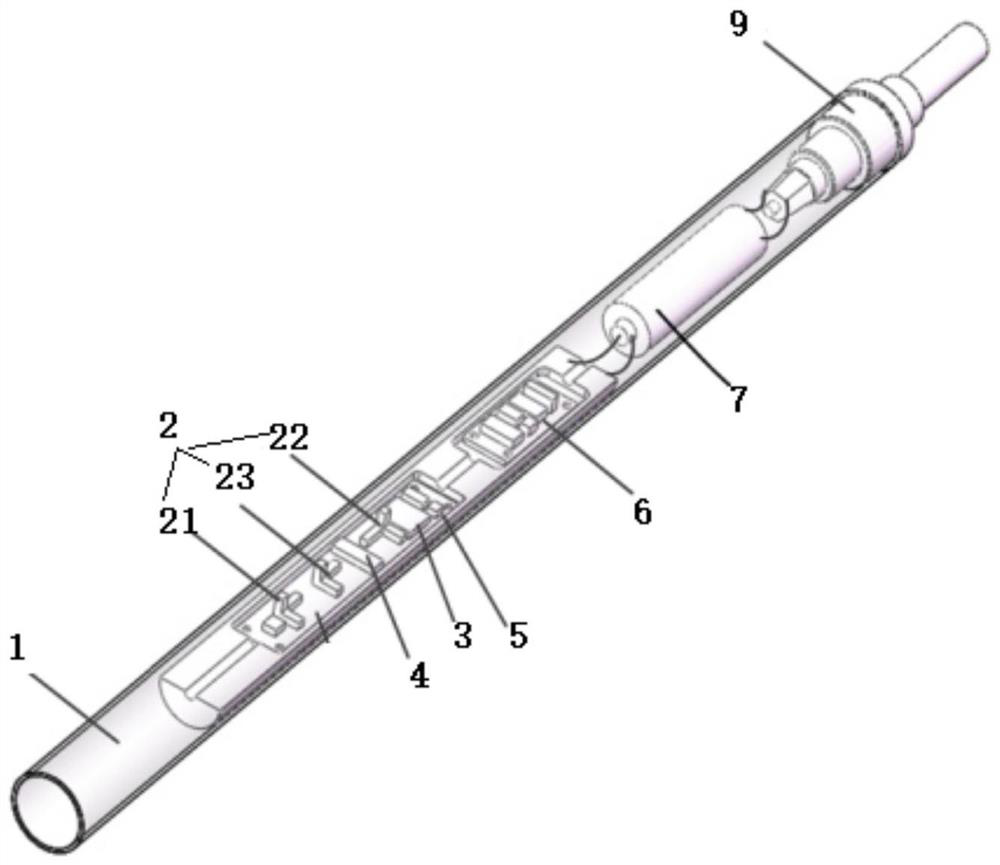

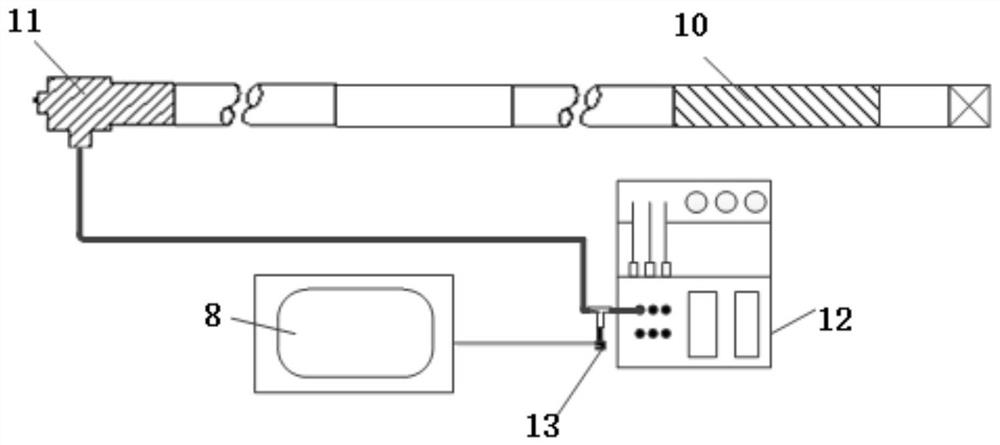

[0058] Such as figure 1 and figure 2 As shown, this embodiment provides a coal mine drilling depth measurement pup, including a measurement pup outer tube 1, and a data acquisition unit 2, a micro control unit 3, a storage unit 4, a Wireless communication unit 5, clock synchronization unit 6 and power supply unit 7;

[0059] The data acquisition unit is connected with the 2 micro-control unit 3, and is used to collect drilling data and transmit the collected data to the micro-control unit 3, and the data acquisition unit 2 includes a triaxial accelerometer for measuring triaxial acceleration 21. A three-axis geomagnetic field sensor 22 for measuring geomagnetic components, and a three-axis gyroscope 23 for measuring three-axis angular velocity;

[0060] When drilling, the micro-control unit 3 controls the three-axis accelerometer 21, the three-axis geomagnetic field sensor 22 and the three-axis gyroscope 23 to collect data, and transmits the collected raw data to the storag...

Embodiment 2

[0072] In this example, the target coal seam to be drilled is a high gas outburst coal seam in a certain coal mine in Huaibei, which belongs to a high gas outburst mine.

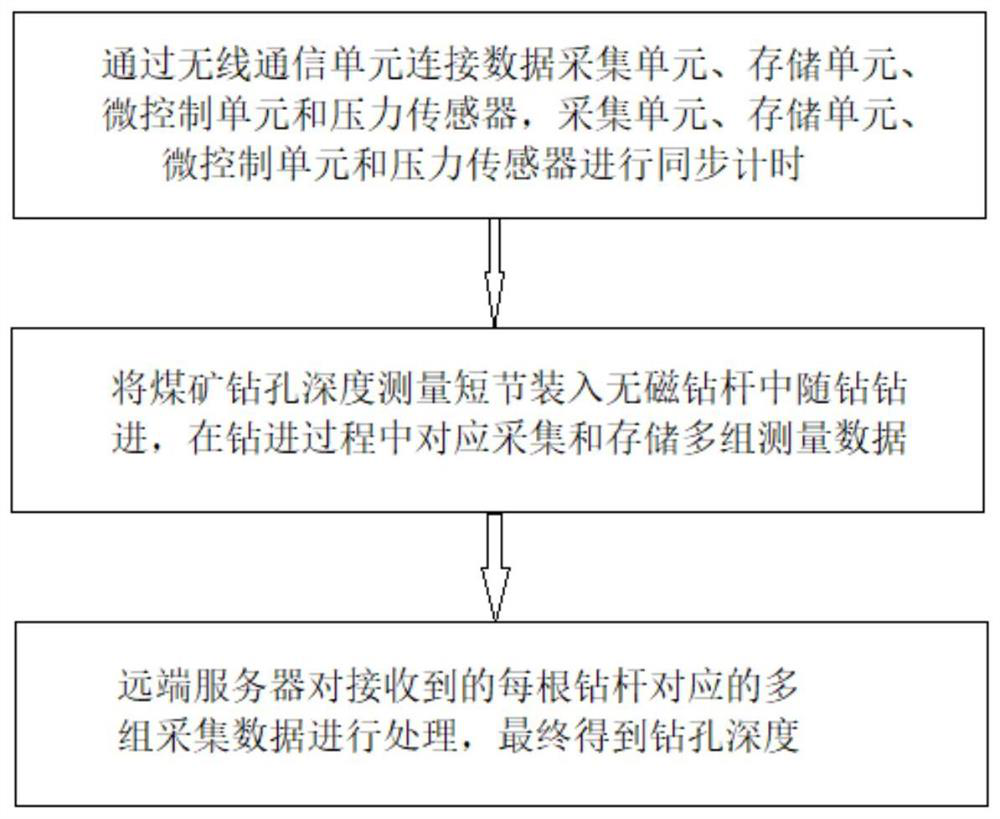

[0073] Such as image 3 As shown, this embodiment discloses a method for determining the depth of a borehole, which is realized by the coal mine borehole depth measurement nipple disclosed in Embodiment 1, and includes the following steps:

[0074] Step 1, connect the data acquisition unit, the storage unit, the micro control unit and the pressure sensor through the wireless communication unit, and the acquisition unit, the storage unit, the micro control unit and the pressure sensor perform synchronous timing;

[0075] Step 2. Put the coal mine drilling depth measurement sub into the non-magnetic drill pipe and drill while drilling. During the drilling process, each time a drill pipe is added, the coal mine drilling depth measurement sub correspondingly collects and stores multiple sets of measurement data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com