Method for evaluating influence of battery production process link on battery consistency

A production process and consistent technology, applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve problems such as reducing the amount of calculation, and achieve the effect of simple calculation process, high reliability and scientificity, and less manual calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

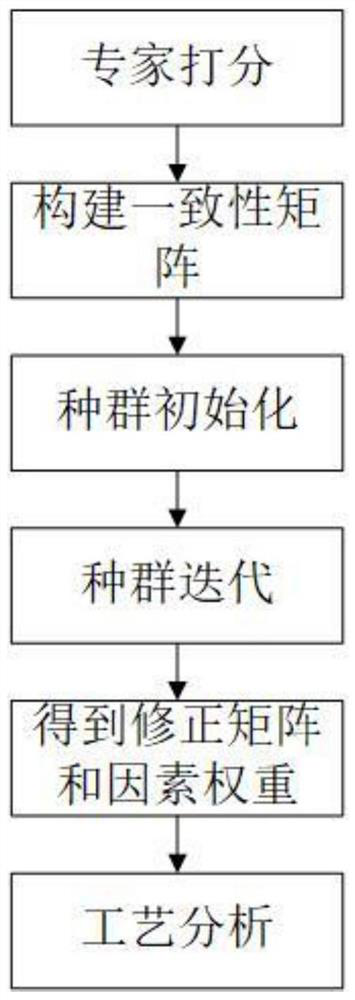

[0048] This embodiment provides a method based on swarm intelligence to evaluate the impact of battery production process on battery consistency. Please refer to figure 1 , the method includes:

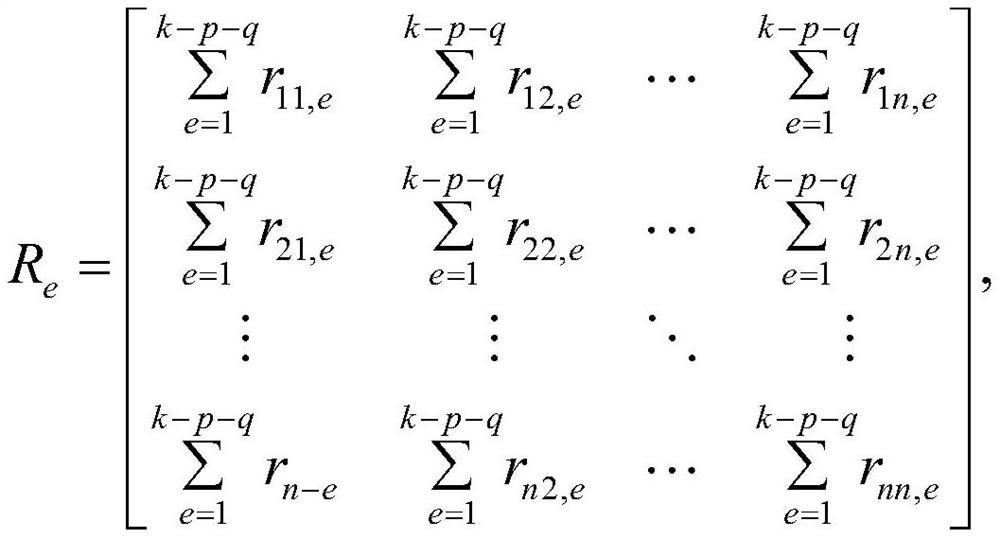

[0049] Step1: Construct an n-dimensional fuzzy consistent matrix R according to the expert scoring table e , the expert scoring table is the preliminary evaluation data of the degree of influence of factors in each process link of battery production on the consistency of the battery;

[0050] Step2: The fuzzy consistent matrix R e Each element in is used as the initial particle swarm, set the maximum number of iterations T, set the consistency optimization function CIF(n) as the fitness function of the particle swarm algorithm, set the particle position value range [0,b] and the particle velocity The value range is [0,c]; the corresponding weight w of each level factor i As optimization variables, a total of (n-1)(n-2) / 2+n optimization variables, i=1,2,...n;

[0051] Step3: Take t...

Embodiment 2

[0056] This embodiment provides a method based on swarm intelligence to evaluate the impact of the battery production process on the consistency of the battery. The actual production process of the pouch battery is used as an example for illustration. The method includes:

[0057] Step 1: Obtain expert scoring data and construct a fuzzy consistency matrix;

[0058] Based on the knowledge reserves of experts and the operating experience of front-line engineers, the professional knowledge and production experience are quantified by designing a scoring mechanism.

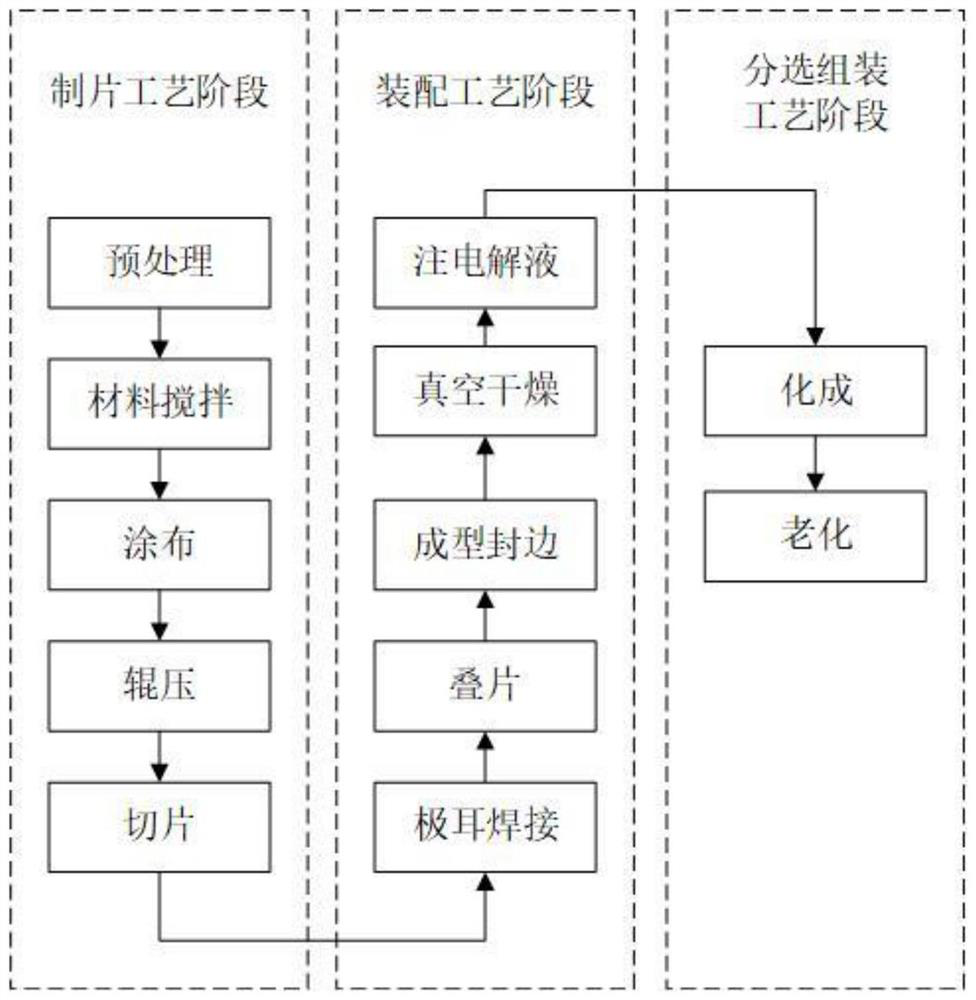

[0059] According to the customary grading method in the industry, the actual production process of the pouch battery is divided into four levels of factor layers. The first level factor layer includes the production process, assembly process and sorting process. Assembly process; the second factor layer includes pretreatment, material mixing, coating, rolling, slicing, tab welding, lamination, forming edge banding, vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com