Industrial Internet of Things and control method for production line balance rate control

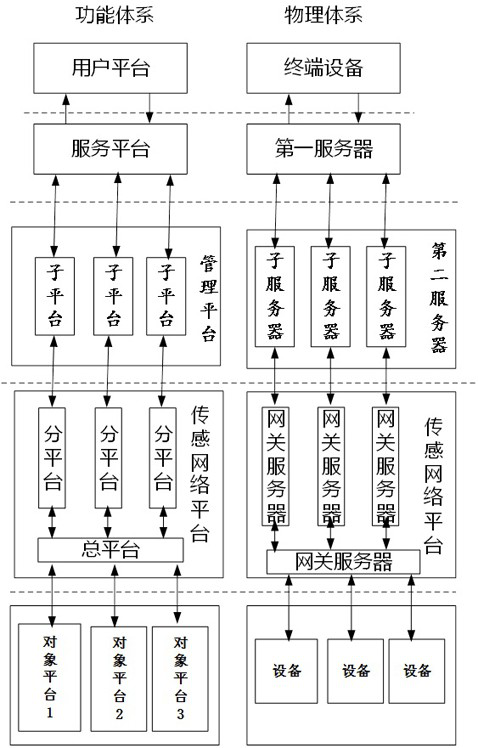

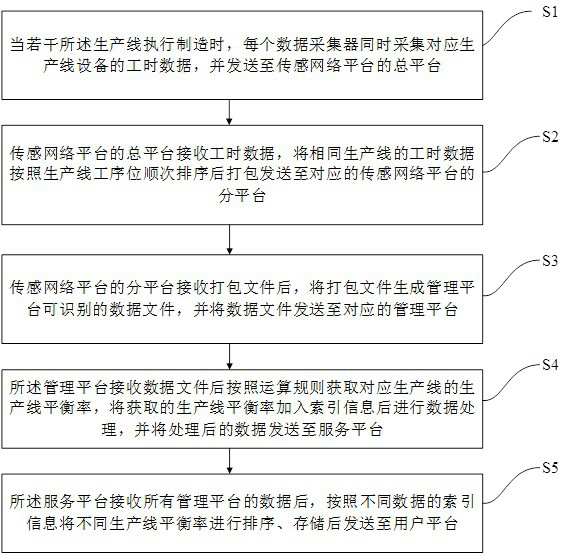

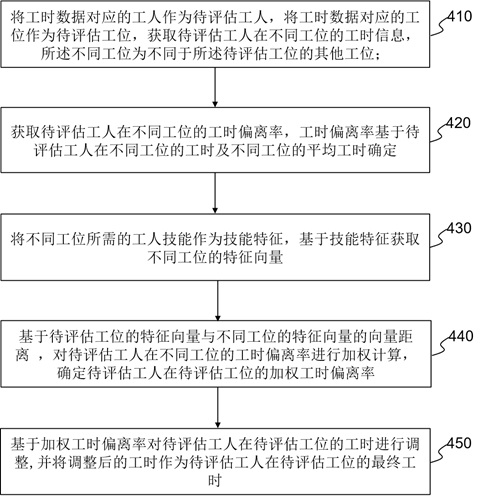

A technology of production line balance rate and industrial Internet of Things, applied in the direction of comprehensive factory control, comprehensive factory control, general control system, etc., can solve the problem of not being able to ensure that the production line balance rate meets production requirements, collecting man-hours is time-consuming and labor-intensive, increasing time-consuming and cost and other issues, to reduce the difficulty and error of human calculation, reduce the pressure of data processing, and reduce the cost of architecture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to illustrate the technical solutions of the embodiments of the present specification more clearly, the following briefly introduces the accompanying drawings used in the description of the embodiments. Obviously, the accompanying drawings in the following description are only some examples or embodiments of the present specification. For those of ordinary skill in the art, the present specification can also be applied to the present specification according to these drawings without any creative effort. other similar situations. Unless obvious from the locale or otherwise specified, the same reference numbers in the figures represent the same structure or operation.

[0017] It should be understood that "system", "device", "unit" and / or "module" as used herein is a method used to distinguish different components, elements, parts, sections or assemblies at different levels. However, other words may be replaced by other expressions if they serve the same purpose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com