Method for predicting axial compression performance of foldable composite cylindrical shell

A composite material, axial compression technology, applied in the field of space navigation, can solve the problems of complex calculation, high cost of axial compression performance of cylindrical shell, and difficult to guarantee calculation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

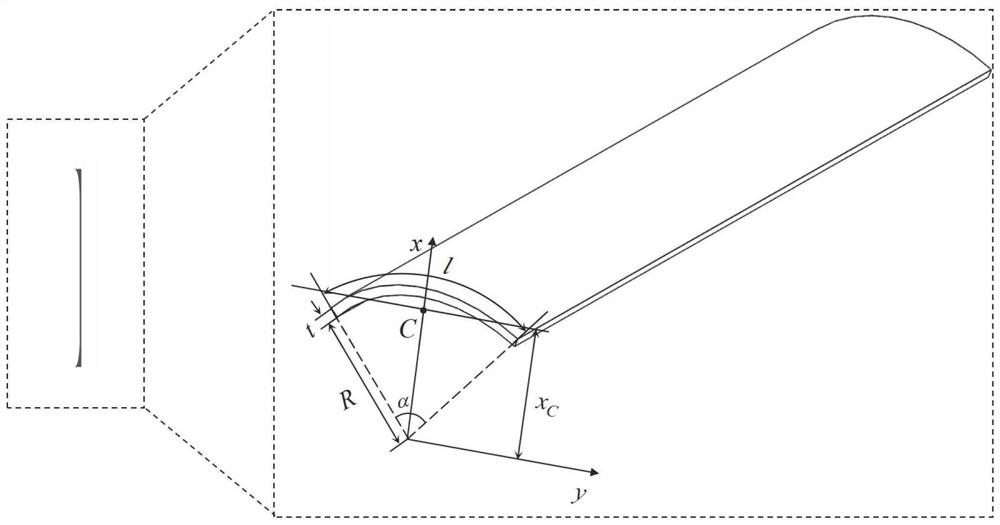

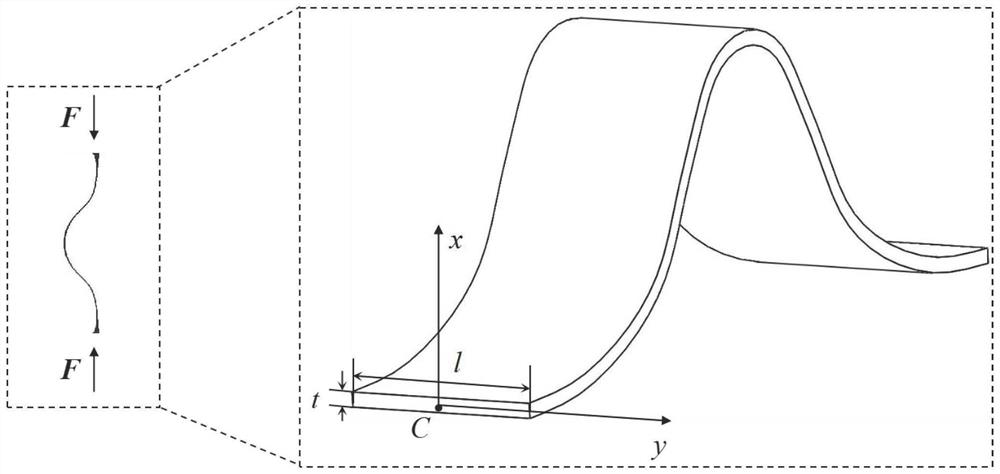

[0178] Step 1. Define the geometric shape and size of the foldable composite cylindrical shell, and determine the mathematical expression of the relationship between various geometric parameters.

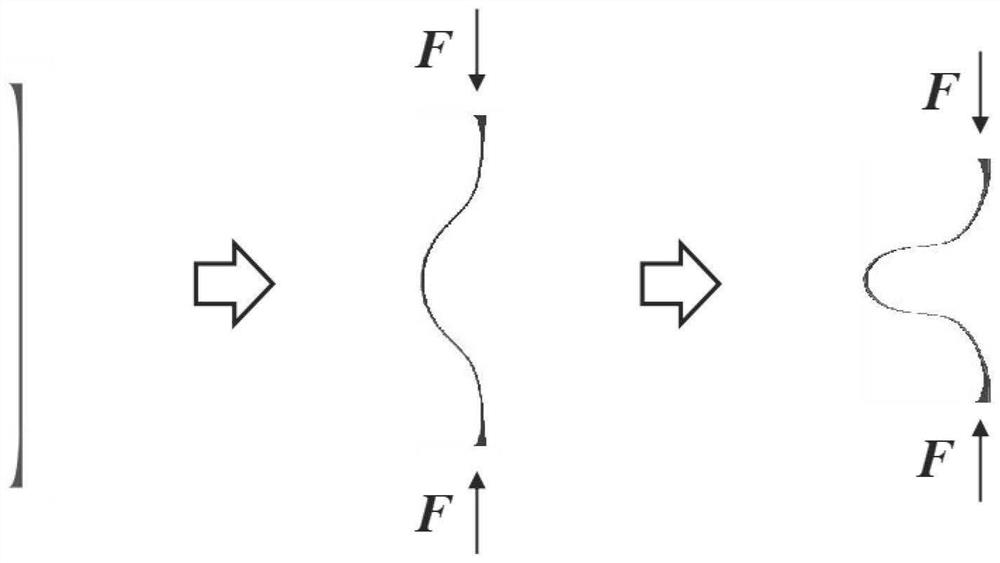

[0179] When the foldable composite cylindrical shell is subjected to axial compression load, buckling and post-buckling phenomena will occur, and the compression process can be divided into three stages. The first stage is a high-stiffness linear stage, which is the linear elastic deformation process of the foldable composite cylindrical shell from the compression load to buckling. The second stage is the cross-sectional transformation stage, in which the compressive load on the foldable composite cylindrical shell drops sharply. The main reason is that after the foldable composite cylindrical shell buckles, the cross-section changes from circular arc to rectangular, so the moment of inertia of the thin shell cross-section drops rapidly, and then the external compressive load drops ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com