Zinc-based single flow battery operation method

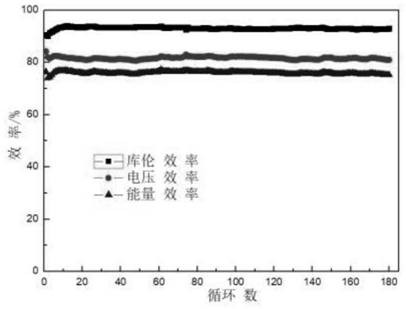

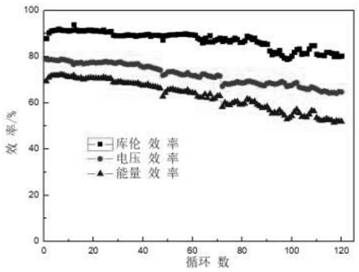

A liquid flow battery and operating method technology, which is applied in the direction of fuel cells, regenerative fuel cells, fuel cell additives, etc., can solve problems affecting battery performance and service life, reduce system energy efficiency, and reduce battery Coulombic efficiency. System pump consumption, reduced system pump consumption, and improved battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

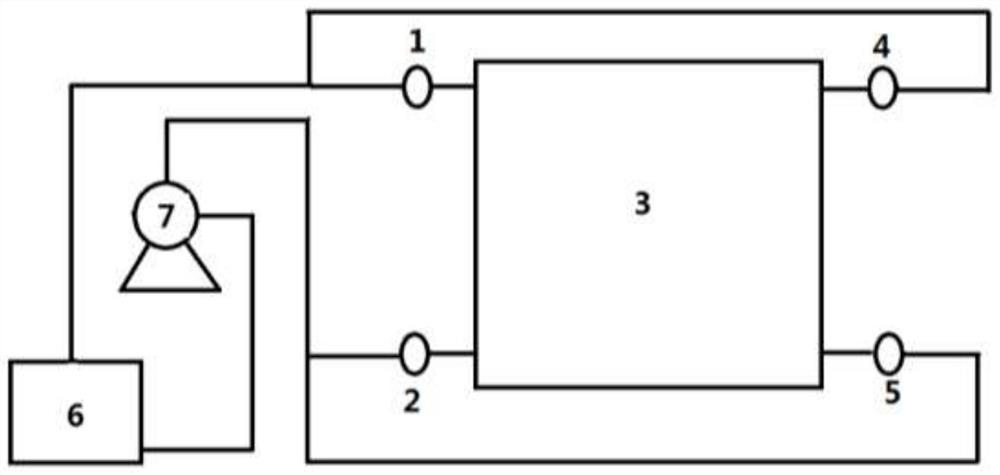

[0030] Zinc-bromine single-flow battery includes 1 electric valve for positive liquid outlet, 2 electric valve for positive liquid inlet, 3 electric stacks, 4 electric valve for negative liquid outlet, 5 electric valve for negative liquid inlet, 6 liquid storage tank, and 7 cycles Pump. The zinc-bromine single flow battery includes a stack 3 formed by connecting five single cells in series; the positive liquid outlet of the electric stack 3 passes through the electric valve 1 of the positive liquid outlet, and the electric valve 4 of the negative liquid outlet passes through the electric valve 4 of the negative liquid outlet and their connecting pipelines are connected to the electrolyte liquid storage tank 6; the positive liquid inlet of the stack 3 is connected to the negative liquid inlet through the electric valve 5 of the negative liquid inlet through the electric valve 2 of the positive liquid inlet , and their connecting pipelines are connected to the electrolyte liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com