Composite diaphragm, preparation method thereof and lithium ion battery

A composite diaphragm and base film technology, applied in secondary batteries, battery pack parts, separators/films/diaphragms/spacers, etc. The effect of reducing the thermal closed cell temperature and improving the safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

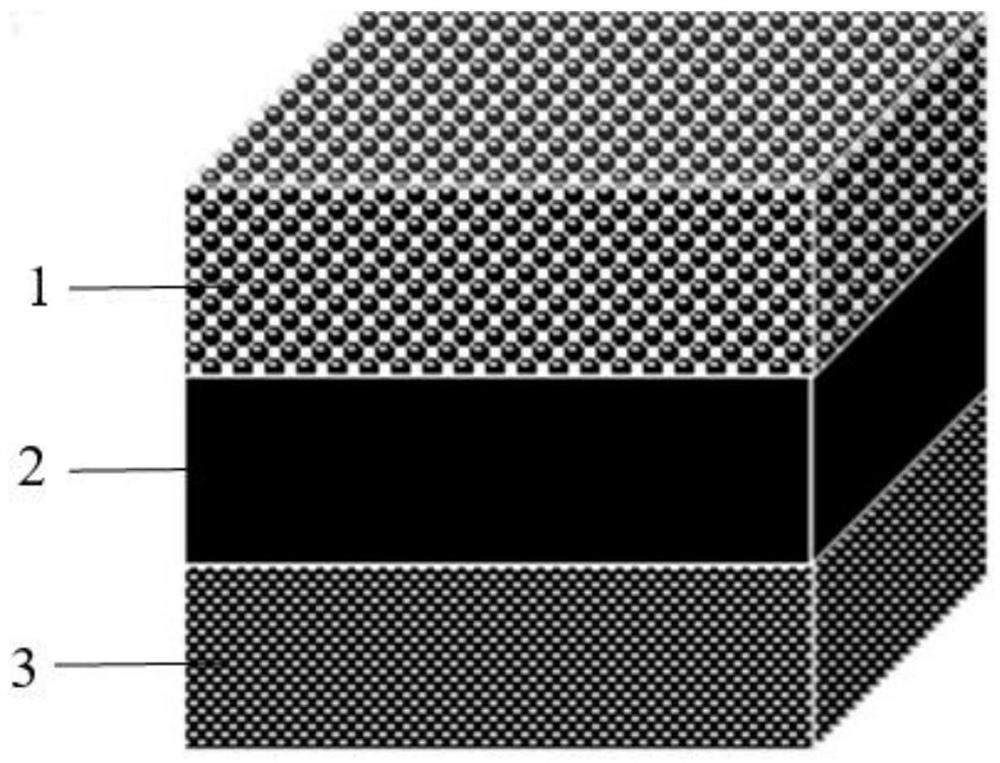

[0072] This embodiment provides a composite diaphragm ( figure 1 ), the composite separator includes a laminated solid electrolyte layer 1, a base film 2 (Celgard 2400) and a polymer microsphere layer 3; the thickness of the solid electrolyte layer is 3 μm, and the thickness of the polymer microsphere layer is 3 μm, and the thickness of the base film is 9 μm.

[0073] In terms of mass percentage, the solid electrolyte layer is composed of 30wt% Al 2 o 3 Composed of 70wt% PVDF (HSV900), surface density is 12g / m 2 The polymer microsphere layer is polyethylene microspheres with a median particle size of 1 μm and an average degree of polymerization of 5000.

[0074] Described preparation method comprises the steps:

[0075] (1) Al 2 o 3 Add N,N-dimethylformamide for ultrasonic dispersion for 15 minutes to form a suspension, add PVDF to the suspension and planetary stir for 30 minutes at a speed of 1200r / min to obtain a solid electrolyte glue, the solid electrolyte glue The ...

Embodiment 2

[0079] This embodiment provides a composite diaphragm ( figure 1 ), the composite separator includes a stacked solid electrolyte layer 1, a base film 2 (Celgard 2400) and a polymer microsphere layer 3; the thickness of the solid electrolyte layer is 2 μm, and the thickness of the polymer microsphere layer is 2 μm, and the thickness of the base film is 8 μm.

[0080] In terms of mass percentage, the solid electrolyte layer is made of 20wt% ferroelectric ceramic material (BaTiO 3 ) and 80wt% PVDF-HFP (Solvay 21510), with an areal density of 11g / m 2 The polymer microsphere layer is polyethylene microspheres, the median particle size is 200nm, and the average degree of polymerization is 2000.

[0081] Described preparation method comprises the steps:

[0082] (1) BaTiO 3 Add N-methylpyrrolidone for ultrasonic dispersion for 5 minutes to form a suspension, add PVDF-HFP to the suspension and planetary stir for 20 minutes at a speed of 1000r / min to obtain a solid electrolyte glue...

Embodiment 3

[0086] This embodiment provides a composite diaphragm ( figure 1 ), the composite separator includes a laminated solid electrolyte layer 1, a base film 2 (Celgard 2400) and a polymer microsphere layer 3; the thickness of the solid electrolyte layer is 5 μm, and the thickness of the polymer microsphere layer is 5 μm, and the thickness of the base film is 10 μm.

[0087] In terms of mass percentage, the solid electrolyte layer is composed of 40wt% super acidic oxide (acidic ZrO 2 ) and 60wt% PVC (S-700), with a surface density of 15g / m 2 The polymer microsphere layer is polyethylene microspheres with a particle size of 2 μm and a degree of polymerization of 10,000.

[0088] Described preparation method comprises the steps:

[0089] (1) the acidic ZrO 2 Add dimethyl sulfoxide for ultrasonic dispersion for 30 minutes to form a suspension, add PVC to the suspension and planetary stir for 40 minutes, the speed is 1500r / min, to obtain a solid electrolyte glue, the viscosity of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com