Preparation method of high-purity deuterated ammonia

A high-purity, deuterated technology, used in the preparation/separation of ammonia, chemical instruments and methods, ammonia compounds, etc., can solve problems such as being unsuitable for large-scale industrial production, easy to burn magnesium powder in the air, and high price of heavy water. , to achieve the effect of small footprint, mature and controllable process route, and reduced raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

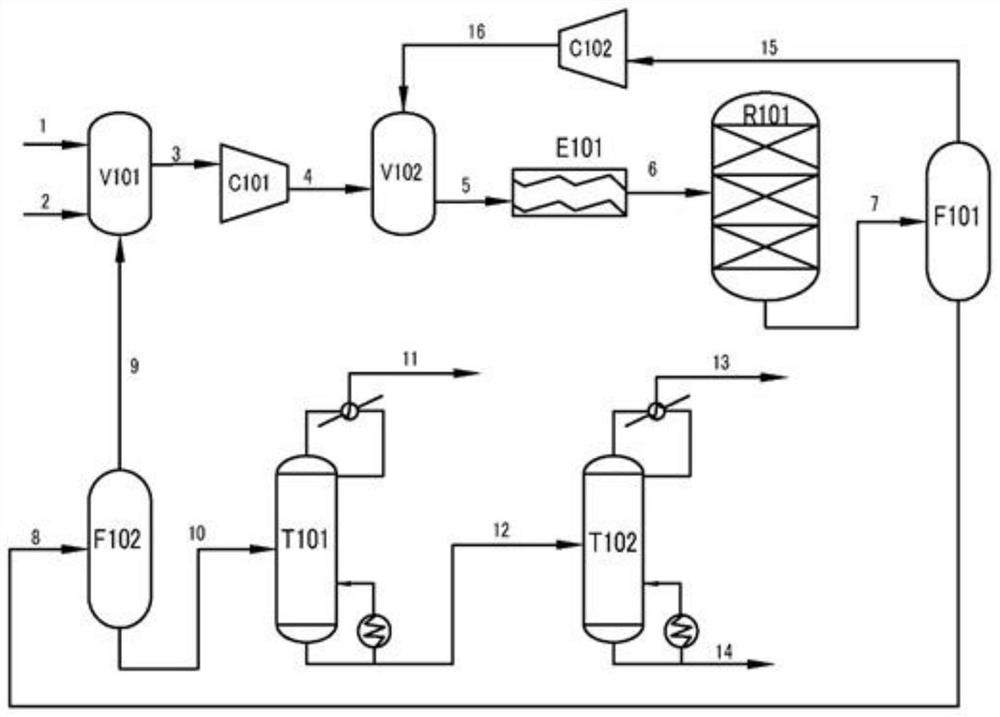

[0032] Such as figure 1 Shown, the preparation method of the high-purity deuterated ammonia of the present embodiment comprises the following steps:

[0033] S1, 12kg of high-purity deuterium 2 with a purity of 99.999% and an abundance of 99.6% and 28kg of high-purity nitrogen 1 with a purity of 99.999% are passed into the feed buffer tank V101 with a pressure of 3MPa, and the mixture is high-purity nitrogen and High-purity deuterium raw material gas 3, high-purity nitrogen and high-purity deuterium raw material gas 3 are pressurized to 15MPa by the feed compressor C101 to obtain pressurized raw material gas 4, and the pressurized raw material gas 4 is combined with After the deuterium nitrogen circulating gas 16 is mixed in the buffer tank V102, the mixed gas 5 is obtained, and the mixed gas 5 is heated to 350°C by the heat exchanger E101 to obtain the heated mixed gas 6, and the heated mixed gas is 6 is passed into the reactor R101 to react to obtain the reaction mixture 7;...

Embodiment 2

[0042] The preparation method of the high-purity deuterated ammonia of the present embodiment, as figure 1 shown, including the following steps:

[0043] S1, 12kg of high-purity deuterium 2 with a purity of 99.999% and an abundance of 99.6% and 28kg of high-purity nitrogen 1 with a purity of 99.999% are passed into the feed buffer tank V101 with a pressure of 3MPa, and the mixture is high-purity nitrogen and High-purity deuterium raw material gas 3, high-purity nitrogen and high-purity deuterium raw material gas 3 are pressurized to 30MPa by the feed compressor C101 to obtain pressurized raw material gas 4, and the pressurized raw material gas 4 is combined with After the deuterium nitrogen circulating gas 16 is mixed in the buffer tank V102, the mixed gas 5 is obtained, and the mixed gas 5 is heated to 300°C by the heat exchanger E101 to obtain the heated mixed gas 6, and the heated mixed gas is 6 is passed into the reactor R101 to react to obtain the reaction mixture 7;

...

Embodiment 3

[0052] The preparation method of the high-purity deuterated ammonia of the present embodiment, as figure 1 shown, including the following steps:

[0053] S1, 12kg of high-purity deuterium 2 with a purity of 99.999% and an abundance of 99.6% and 28kg of high-purity nitrogen 1 with a purity of 99.999% are passed into the feed buffer tank V101 with a pressure of 3MPa, and the mixture is high-purity nitrogen and High-purity deuterium raw material gas 3, high-purity nitrogen and high-purity deuterium raw material gas 3 are pressurized to 15MPa by the feed compressor C101 to obtain pressurized raw material gas 4, and the pressurized raw material gas 4 is combined with After the deuterium nitrogen circulating gas 16 is mixed in the buffer tank V102, the mixed gas 5 is obtained, and the mixed gas 5 is heated to 350°C by the heat exchanger E101 to obtain the heated mixed gas 6, and the heated mixed gas is 6 is passed into the reactor R101 to react to obtain the reaction mixture 7;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com