Graphene reinforced concrete and preparation method thereof

A technology of reinforced concrete and graphene, which is applied in the field of building materials, can solve the problems of reducing bearing capacity and service life, corrosion of steel bars, and difficulty in being replaced, and achieves the effects of easy industrial construction, reducing voids, and reducing material damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

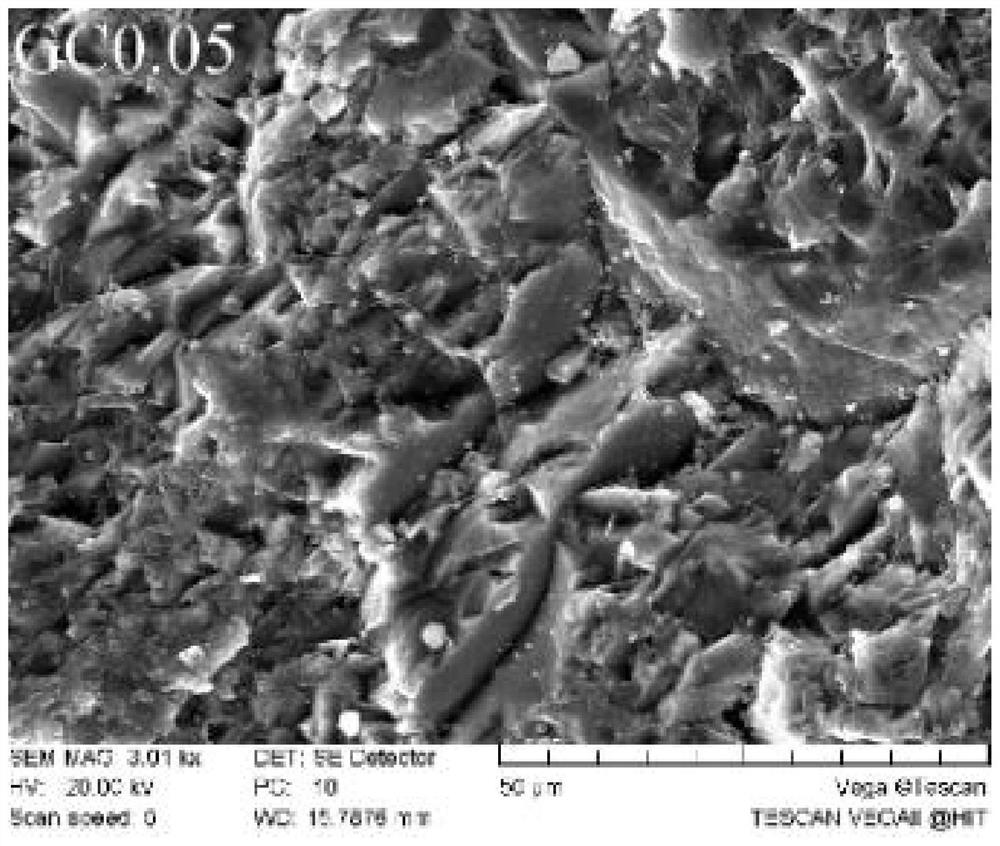

Image

Examples

Embodiment 1

[0018] A graphene-reinforced concrete, comprising the following components by weight: 200 parts of PO42.5 portland cement, 120 parts of water, 20wt% water content, 10 μm in plane size, 60 parts of graphene with a thickness of 20nm, and a diameter of 20mm 500 parts of coarse sand and 300 parts of fine sand with a particle size of 2 mm.

Embodiment 2

[0020] A graphene-reinforced concrete, comprising the following components by weight: 150 parts of PO42.5 Portland cement, 80 parts of water, 20wt% water content, 10 μm in plane size, 1.5 parts of graphene with a thickness of 20nm, and a diameter of 15mm 500 parts of coarse sand and 380 parts of fine sand with a particle size of 5mm.

Embodiment 3

[0022] A graphene reinforced concrete, comprising the following components by weight: 160 parts of PO42.5 portland cement, 60 parts of water, 20 wt% water content, 10 μm in plane size, 12 parts of graphene with a thickness of 20nm, and a diameter of 15mm 550 parts of coarse sand and 400 parts of fine sand with a particle size of 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plane size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com