Electrodeposition preparation method and device for super-hydrophobic structure on inner wall of pipeline

An electrodeposition and super-hydrophobic technology, applied in the direction of electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of high cost, uncontrollable, complex devices, etc., and achieve the effects of reducing stray deposition, stable gaps, and strong selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

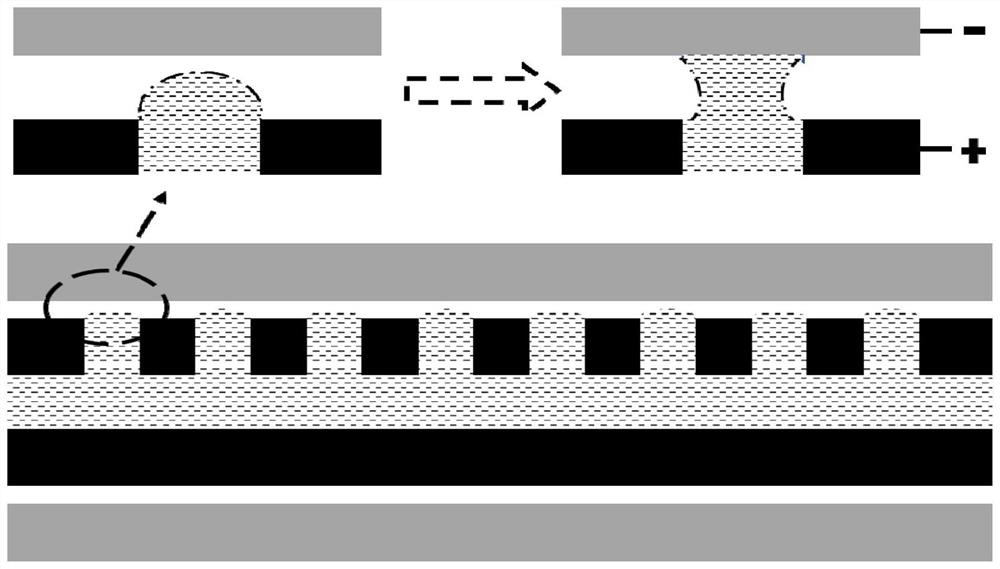

[0048] A preparation method for electrodeposition of a superhydrophobic structure on the inner wall of a pipeline, comprising the steps of:

[0049] Holes are opened on one side of the tubular anode 8 according to the required microstructure size;

[0050] Set the rotation speed and intermittent time according to the required microstructure style, and import it into computer 1 after optimization;

[0051]The inner wall of the workpiece pipeline 9 is pretreated, and chemical methods can be used to roughen the surface of the inner wall to improve the bonding force of the microstructure;

[0052] The tubular anode 8 is connected to the positive pole of the DC pulse power supply 3, and the workpiece pipeline 9 is connected to the negative pole of the DC pulse power supply 3;

[0053] Turn on the peristaltic pump 4, slowly feed the deposition solution, so that the interior of the tubular anode 8 is filled with the deposition solution and form tiny droplets at the opening at the to...

Embodiment

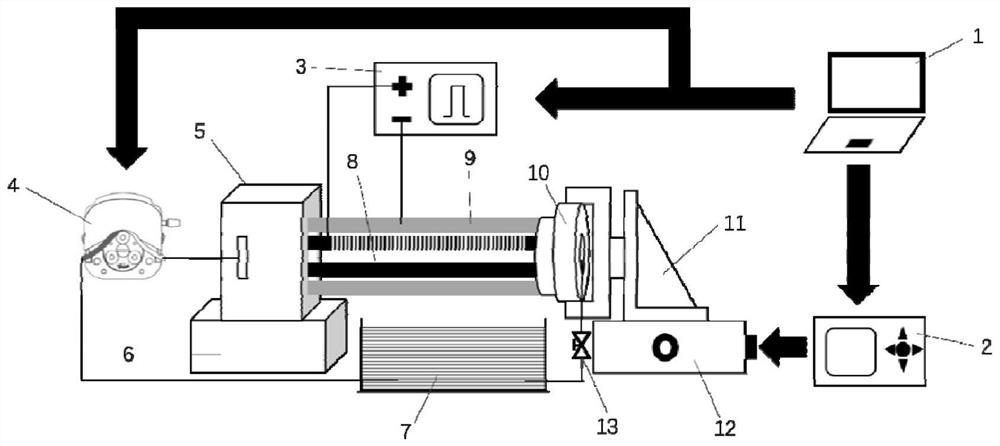

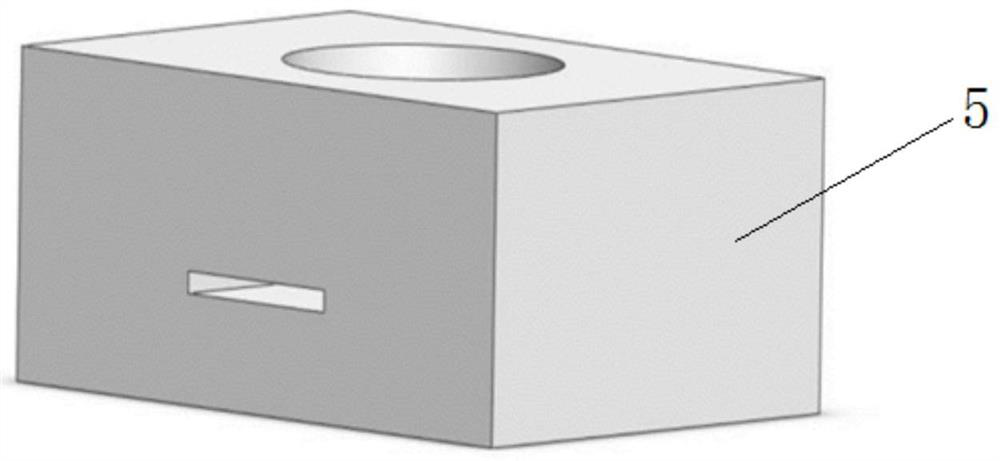

[0065] combined with figure 1 As shown, an electrodeposition preparation device with a superhydrophobic structure on the inner wall of the pipeline includes an electrodeposition processing system, a deposition liquid circulation system and a motion control system; the electrodeposition processing system includes a DC pulse power supply 3, a tubular anode 8 and a workpiece pipeline 9 The tubular anode 8 is connected to the positive pole of the DC pulse power supply 3, the workpiece pipeline 9 is connected to the negative pole of the DC pulse power supply 3, and a certain working gap is guaranteed by the liquid inlet fixture 5 and the liquid outlet fixture 10; the motion control system includes a computer 1 and a motion controller 2; the computer 1 controls a motion controller 2, a peristaltic pump 4 and a DC pulse power supply 3, and the motion controller 2 controls an x-y-z three-axis motion platform 12 and a rotating arm 11; the electrodeposition liquid circulates The system ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com